The terms "packing machine" and "packaging machine" are often used interchangeably in industry, and in practice, they generally refer to the same type of equipment. However, there can be a subtle distinction in their emphasis:

Packing Machine:

Focus: The core process of placing the product into a container or wrapping it.

Emphasis: On the physical act of enclosing or loading the product. It highlights the action of putting items into boxes, bags, or around wrapping material.

Example: A machine that loads individual bottles into a cardboard case, or a machine that wraps a single chocolate bar in foil.

Packaging Machine:

Focus: The broader concept of creating the package, which includes protection, containment, labeling, and preparation for distribution and sale.

Emphasis: On the final package as a complete unit, considering its role in marketing, safety, shelf life, and logistics. It encompasses the entire process from product insertion to sealing and sometimes labeling.

Example: An integrated system that fills a pouch with product, seals it, checks the seal integrity, and applies a date code.

In Summary:

"Packing" often emphasizes the mechanical action of filling or enclosing.

"Packaging" often emphasizes the overall process and the final packaged product, including its function and appearance.

However, in everyday industrial and commercial use, the difference is negligible. Both terms are used to describe machines that automate the process of enclosing products in containers or materials. You'll find manufacturers and suppliers using both terms to describe the same equipment. The choice of word often depends on regional preferences or company terminology rather than a strict technical difference.

The automation levels in packing and packaging machines aren't inherently different based on the terminology (packing vs. packaging), as the distinction between the two terms is minimal (as explained previously). Instead, automation levels vary across the entire spectrum of packaging/packing equipment based on function, scale, and integration.

However, we can describe the general levels of automation found in modern packaging/packing machinery, which apply to both terms:

1. Manual Machines

Operation: Require significant human labor for most steps (loading product, placing into packaging, sealing, labeling).

Use Case: Very small businesses, startups, or specialized products.

Example: A hand-operated heat sealer for pouches; a manual box tucker.

2. Semi-Automatic Machines

Operation: Automate one or two key processes (like sealing or filling), but still require an operator to load products, position packaging, or remove finished packages.

Use Case: Small to medium businesses with moderate production needs.

Example: A semi-automatic case packer where an operator places products into a jig, and the machine closes and seals the box.

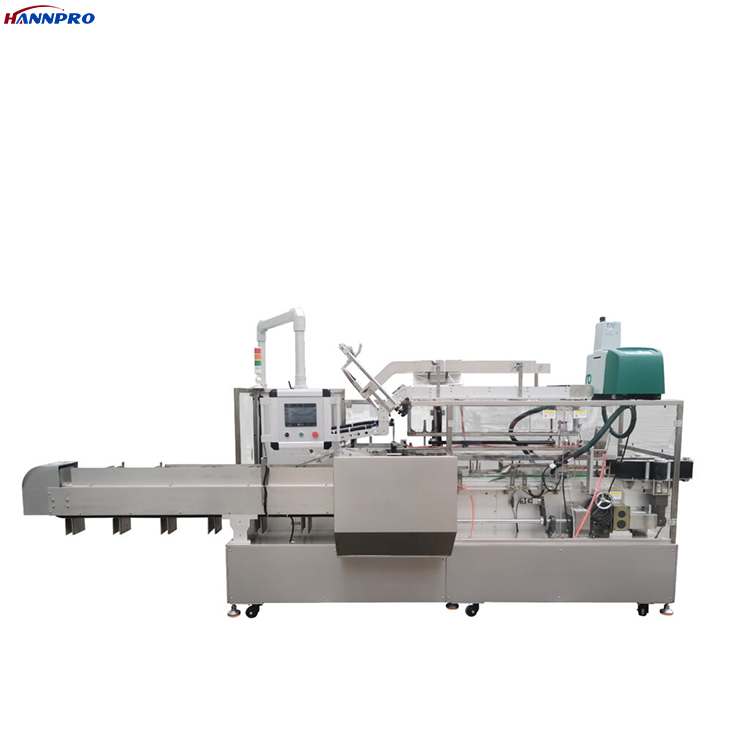

3. Automatic Machines

Operation: Run continuously with minimal human intervention. They automatically feed products, form packages, fill, seal, and eject finished units. An operator typically monitors the machine and replenishes packaging materials.

Use Case: Medium to large-scale production.

Example: An automatic flow wrapper that forms, fills, and seals individual products on a conveyor line.

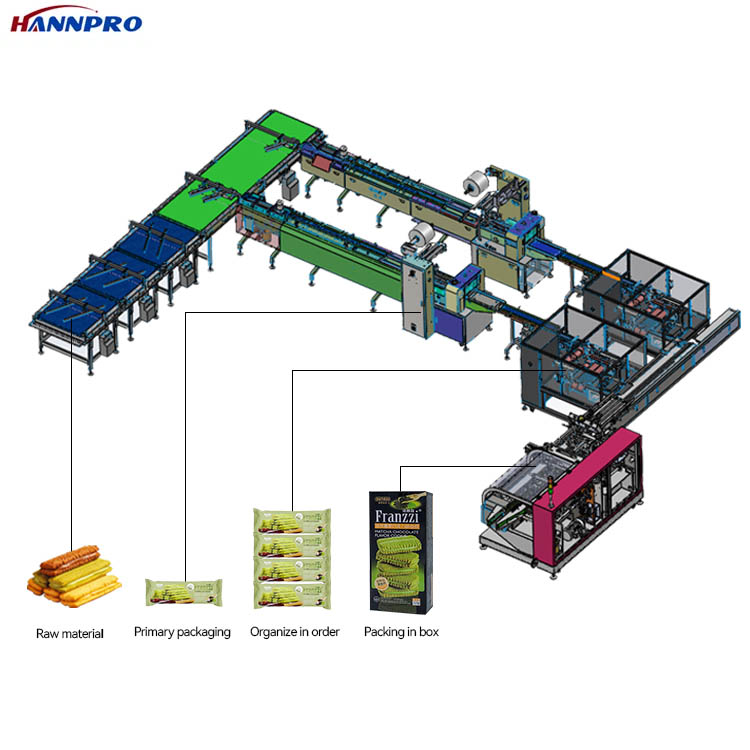

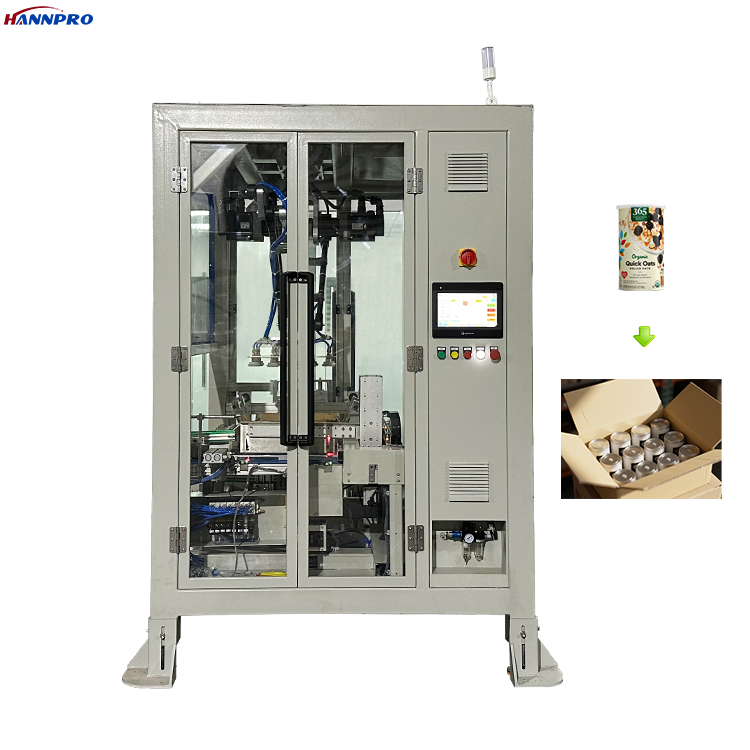

4. Fully Automatic / Integrated Lines

Operation: Multiple machines (fillers, cappers, labelers, packers, case packers, palletizers) are linked by conveyors and controlled by a central system (often with PLCs and SCADA). These lines handle the entire process from bulk product to palletized finished goods with very little manual labor.

Use Case: High-volume industrial production.

Example: A complete wafer biscuit line: baking → cooling → automatic filling & laminating → cutting → counting → flow wrapping → case packing → sealing → palletizing.

Key Automation Features Across Levels:

Sensors & Feedback: Detect product presence, fill levels, seal integrity.

Programmable Logic Controllers (PLCs): Control machine sequences and logic.

Human-Machine Interface (HMI): Touchscreens for operators to monitor and adjust settings.

Robotics: Used in high-end systems for picking, placing, packing, and palletizing.

Vision Systems: For quality inspection, label verification, and alignment.

In essence: Whether called "packing" or "packaging" machines, their automation can range from simple manual devices to highly sophisticated, fully integrated robotic systems. The level chosen depends on production volume, labor costs, product complexity, and budget.