The Wafer biscuit automatic material sorting and packaging line is an automated solution specially designed to meet the efficient and precise packaging requirements of wafer biscuits.

Such production lines usually integrate multiple functional modules, aiming to enhance production efficiency Wafer Biscuit Packaging Machine, reduce manual intervention and ensure the consistency of product quality Wafer Biscuit Packing Machine.

The wafer biscuit automatic material sorting and packaging line is a key equipment for the automated production of wafer biscuits. It mainly realizes the processes of biscuit sorting, arrangement, measurement and packaging, which can significantly improve production efficiency, reduce labor costs and ensure packaging quality Wafer Biscuit Packing Machine. The following is a detailed introduction from aspects such as equipment composition, working process, advantages and features Wafer Biscuit Packaging Machine, and application scenarios:

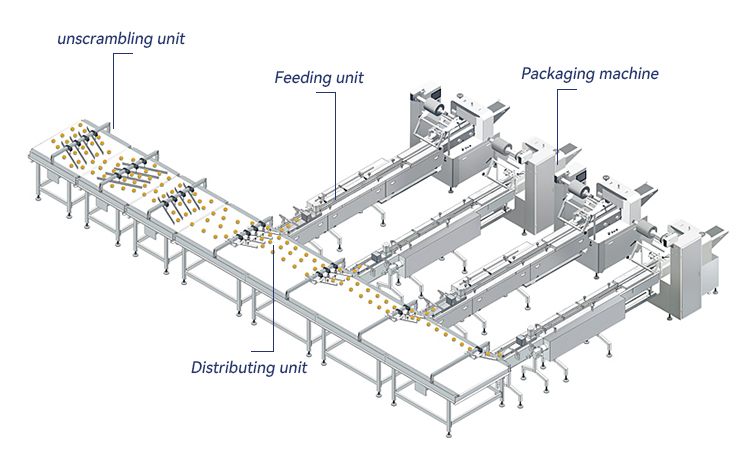

I. Equipment Composition

The Wafer biscuit automatic material sorting and packaging line is usually composed of multiple functional modules working together Wafer Biscuit Packaging Machine, specifically including:

Material handling system

Conveying device: Cookies are conveyed from the front end of the production line to the material sorting area through a conveyor belt. Common types include belt type and chain plate type Wafer Biscuit Packing Machine.

Sorting mechanism: Orient, sort and stack the disordered cookies to ensure they are neatly arranged in a unified direction (such as flat or upright) Wafer Biscuit Packing Line. Common methods include vibration sorting and fork sorting, etc.

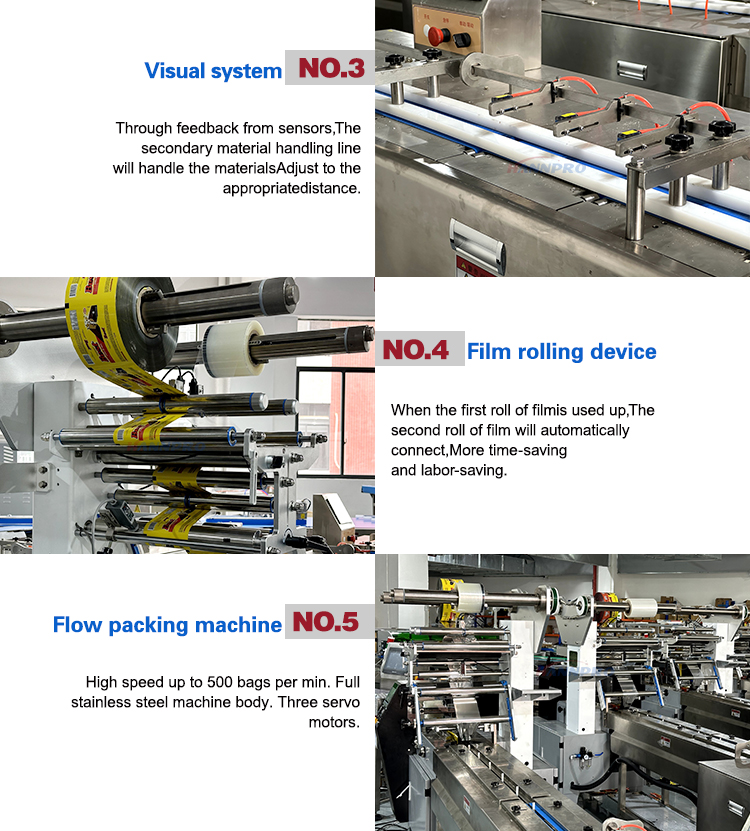

Detection and rejection device: Through photoelectric sensors or visual inspection systems Wafer Biscuit Packing Line, damaged or corner-missing cookies are removed to ensure the quality of products entering the packaging process Wafer Biscuit Packing Machine.

Metering and material distribution system

Quantitative device: It precisely counts and groups cookies according to packaging specifications (such as 5 or 10 pieces per bag). Common equipment includes rotary table counters and servo motor-driven dispensers, etc Wafer Biscuit Packing Machine.

Material distribution mechanism: Accurately distribute the measured biscuit groups to the packaging station Wafer Packing Machine. It can be combined with a buffer conveyor belt or a mechanical hand to achieve flexible material distribution Wafer Biscuit Packing Machine.

Packaging system

The main unit of the packaging machine: It can complete functions such as bag making, filling, sealing, and date printing, and supports various packaging forms Wafer Packing Machine, such as pillow packaging, vertical packaging, and box packaging.

Sealing device: Select heat sealing, cold sealing or ultrasonic sealing method based on the packaging material (such as plastic film, aluminum foil paper) to ensure a firm and aesthetically pleasing seal Wafer Biscuit Packing Machine.

Printing device: Integrated inkjet printer or heat transfer printer, printing production date, shelf life, batch and other information on packaging film Wafer Packing Machine.

Auxiliary system

Control system: Full-process automated control is achieved through PLC (Programmable Logic Controller) or industrial control computer, supporting parameter setting, fault alarm and production data monitoring.

Dust removal and cleaning device: It removes biscuit debris during the material sorting and packaging processes, keeps the equipment clean, and meets the food production safety standards Wafer Biscuit Packing Machine.

Finished product conveying and palletizing: The packaged products are conveyed to the buffer area or automatic palletizing machine to complete the stacking of finished products, facilitating subsequent storage and transportation Wafer Biscuit Packing Machine.

Ii. Work Process

Cookie input:

The cookies output from the wafer cookie production line (such as the baking and cooling lines) are conveyed into the sorting and packaging line by the conveyor. At this point, the cookies may be in a disordered state Wafer Biscuit Packing Machine.

Sorting and organizing

The material handling system separates and arranges the cookies one by one through vibration, forks and other means, while the detection device removes the substandard products Wafer Biscuit Packing Machine.

Measurement and material distribution

The quantitative device counts the qualified biscuits (such as grouping by the set quantity), and the feeding mechanism pushes each group of biscuits to the feeding port of the packaging machine.

Packaging operation:

The packaging machine automatically completes steps such as taking out the film, making bags, filling cookies, sealing, and printing the date, forming independently packaged products Wafer Biscuit Packing Machine.

Finished product output

The packaged wafer cookies are conveyed out by the conveyor and can be connected to the automatic cartoning machine or palletizing machine to complete the final product processing Wafer Biscuit Packing Machine.

Iii. Core Advantages and Characteristics

High-efficiency automation

The production speed can reach 50 to 200 packs per minute (depending on the biscuit specifications and packaging forms), significantly enhancing production capacity and reducing manual intervention.

Full-process linkage control reduces errors in manual material arrangement, counting and packaging, and enhances production stability Wafer Biscuit Packing Machine.

Flexibility and compatibility

It supports various biscuit specifications (such as single pieces and multi-piece combinations) and packaging forms. The product type can be switched by changing the mold or adjusting the parameters.

Compatible with different packaging materials (such as transparent film, composite film) and packaging bag sizes (such as small retail size, large household size) Wafer Biscuit Packing Machine.

Quality Assurance

The material preparation process is gentle, reducing the damage caused by cookies due to collision. The detection device removes defective products in real time to ensure the qualified rate of products leaving the factory Wafer Biscuit Packing Machine.

The sealing is firm and the printing is clear, meeting the requirements of sealing and traceability for food packaging.

Hygiene and Safety

The equipment is made of food-grade stainless steel, with a smooth surface that is easy to clean, and complies with GMP (Good Manufacturing Practice for Pharmaceuticals) and HACCP (Hazard Analysis and Critical Control Points) standards.

It is equipped with safety protection devices (such as emergency stop buttons and guardrails) to prevent operators from accidentally touching the moving parts Wafer Biscuit Packing Machine.

Data-driven management

The control system can monitor data such as production speed, packaging quantity, and equipment operation status in real time, support the generation of production reports and fault early warning, and facilitate factory management optimization Wafer Biscuit Packing Machine.