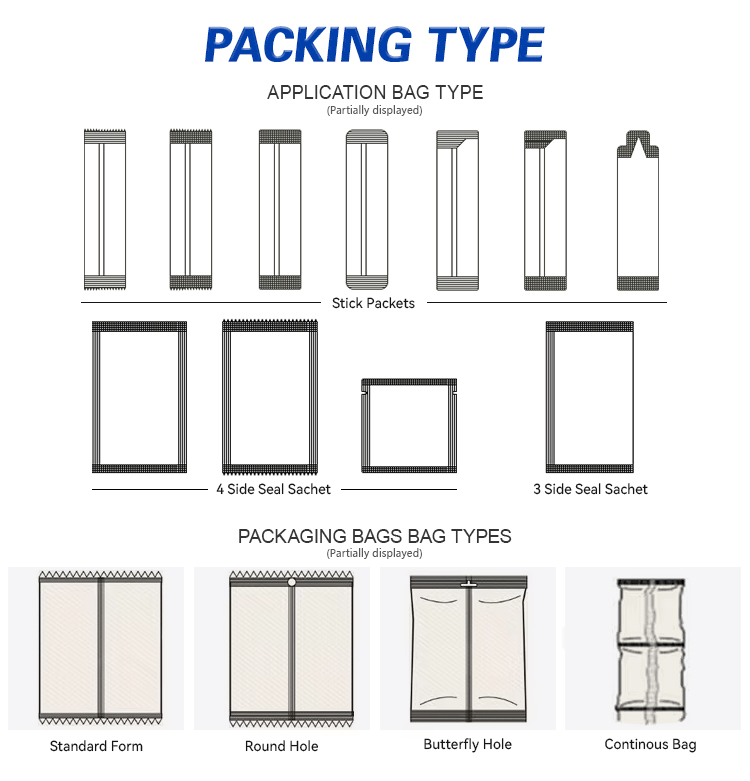

Used for sorting, collecting, and pillow-type medium packaging of items such as bar bags and small bags.

Application Areas

Mainly used in the pharmaceutical, health supplement, and food industries coffee stick packaging machine. In the pharmaceutical industry, it can be used for bag sorting and collection of small bags of granular and powdered medicines, as well as for intermediate packaging coffee stick packaging machine. In the food industry, it can be used for intermediate packaging of small packages of foods such as oatmeal and soy milk, improving production efficiency and product packaging quality coffee stick packaging machine.

Working Principle

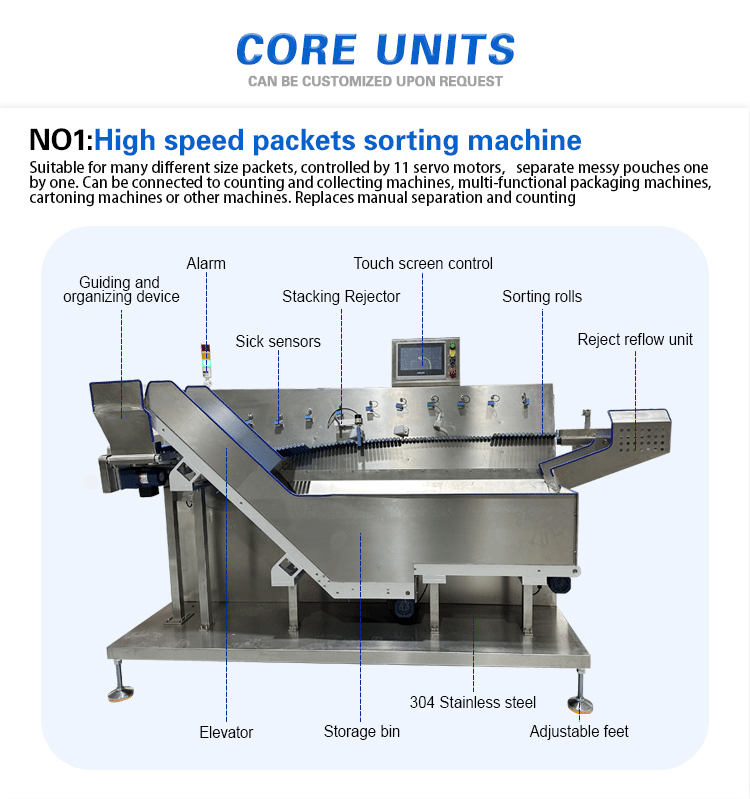

Bag Sorting and Collection Principle: Bagged materials are fed through a low-platform, large-angle, large-capacity storage bin, and then transported to the bag sorting area via a matrix-style multi-stage synchronized feeding design coffee stick packaging machine. Each workstation is equipped with a precision motion control system and a photoelectric detection real-time feedback system to inspect and adjust the bags, ensuring orderly arrangement and accurate counting. Non-conforming bags are automatically rejected coffee stick packaging machine.

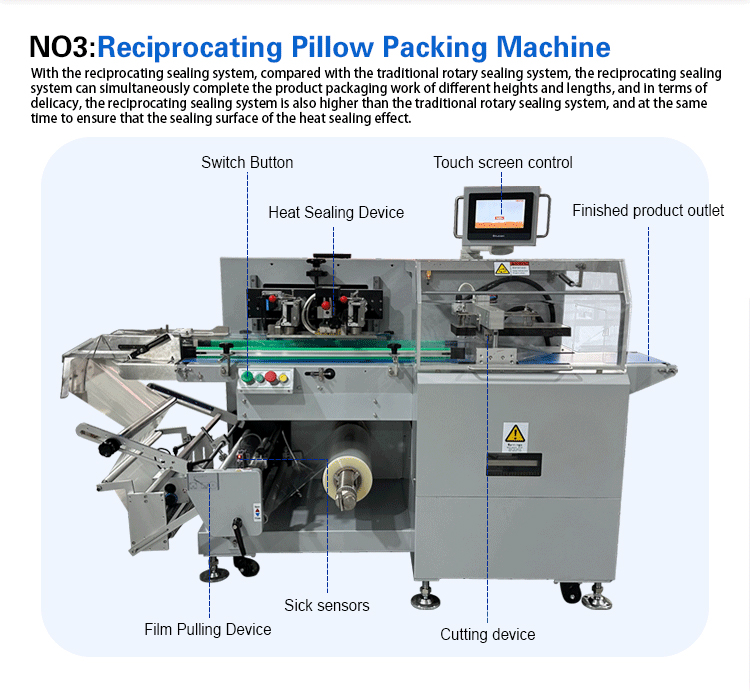

Pillow Packaging Principle: Rolled packaging film is fed into the forming unit via guide rollers and tensioning devices, where it is folded into a U-shaped or cylindrical cavity coffee stick packaging machine. The items to be packaged, such as strip-shaped pouches, are conveyed into the packaging area via a conveyor belt and aligned with the film. The film is longitudinally sealed on both sides using heating rollers or ultrasonic devices, forming a closed tubular structure coffee stick packaging machine. When the product reaches the set position, the transverse sealing mechanism completes the transverse sealing through heating and pressure, simultaneously cutting the packaging film to form an independent pillow-style intermediate packaging unit coffee stick packaging machine.

Functional Features

Bag Sorting Function: Capable of automatically sorting various types of bagged materials, including pillow bags, soft bags, granular bags, aluminum foil bags, and strip bags. Equipped with a fully servo-driven intelligent drive system, multiple servo motors, and a multi-axis high-precision servo intelligent control system, ensuring high-speed, smooth, and orderly automatic arrangement of materials.

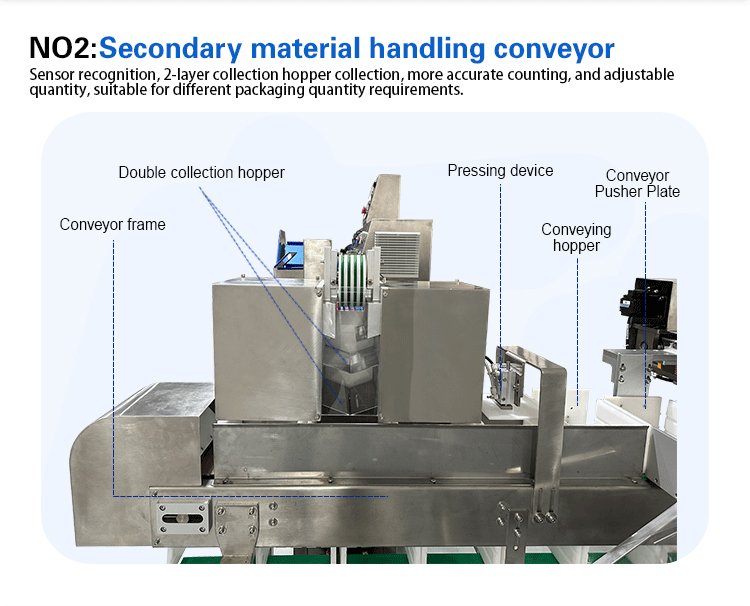

Collection Function: Collects and organizes sorted bags. Some models feature precise counting and waste removal functions, enabling the entire process from material supply, distribution, automatic sorting, distance control to output to be completed without manual intervention coffee small bag packaging machine, ensuring process continuity and product quality. Maximum speed reaches 400 bags per minute, with a stacked or consecutive bag probability below 0.009%.

Pillow-style medium-sized packaging: Using pillow-style packaging, collected small bags or items are wrapped in packaging film, which is then sealed by longitudinal and transverse sealing mechanisms and cut to form independent medium-sized packaging units coffee small bag packaging machine. During the packaging process, the intelligent control system precisely controls parameters such as bag length, sealing temperature, and packaging speed to accommodate different products and packaging materials coffee small bag packaging machine.