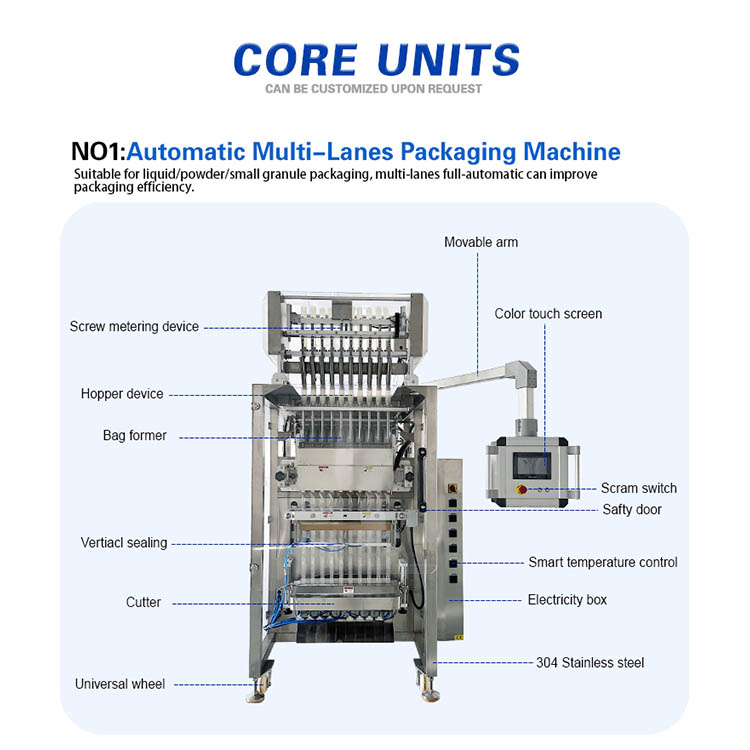

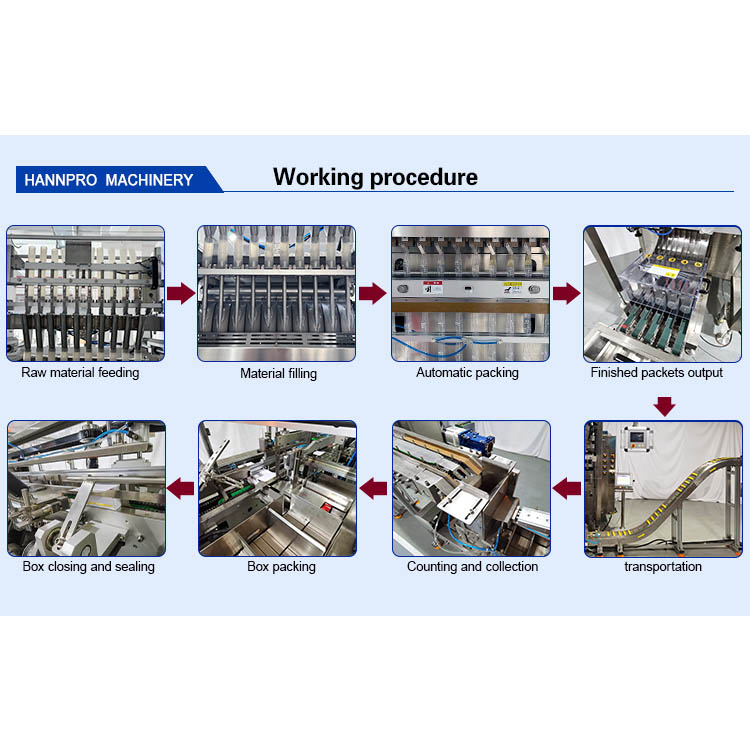

The milk powder packaging machine is an automated packaging equipment specifically used for powder materials. This machine can carry out packaging work in multiple channels (multiple columns)simultaneously, greatly improving production efficiency and packaging speed. Milk powder packaging machine usually can automatically complete a series of operations such as measurement, bag making, filling and sealing, and can adjust the size and packaging capacity of the packaging bag according to different needs milk powder packing machine.

The multi-column automatic packaging machine for milk powder is an automated packaging equipment specifically designed for powdered products such as milk powder. It can ensure efficient production while guaranteeing the accuracy and sealing of packaging. This kind of machine is particularly suitable for the needs of large-scale production, which can significantly improve production efficiency and reduce labor costs milk powder packing machine.

Main features

Multi-column design: Supports simultaneous packaging of multiple channels, greatly enhancing production efficiency milk powder packaging machine.

High-precision metering system: Advanced weighing or volumetric metering devices are adopted to ensure the accurate weight of each bag of milk powder milk powder filling machine.

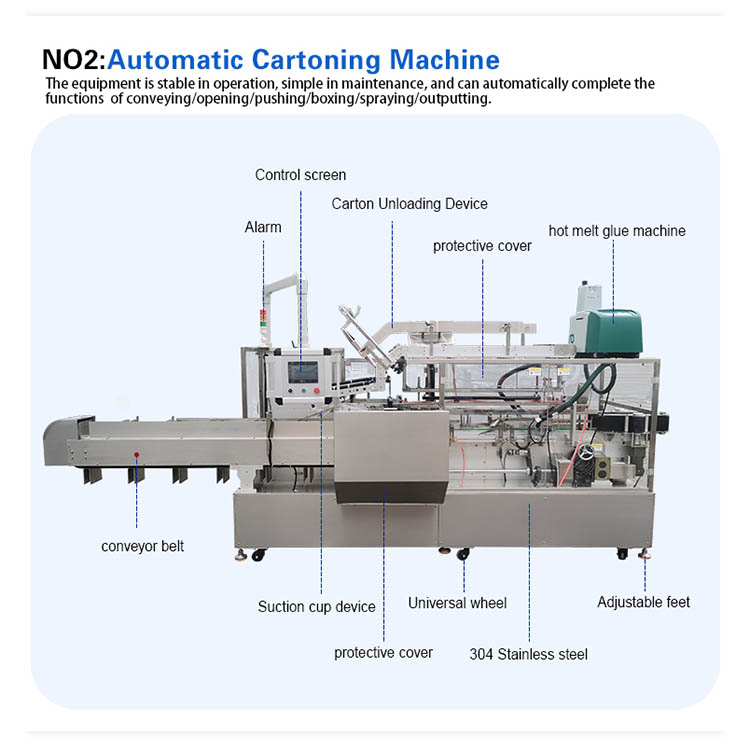

Automated operation process: A series of operations from bag making, filling, sealing to cutting can all be completed automatically, reducing manual intervention milk powder packaging machine.

Strong applicability: It can not only be used for milk powder, but also for other powdered materials with similar properties, such as coffee powder, medicinal powder, etc.

Easy to clean and maintain: Considering hygiene requirements milk powder packaging, the design emphasized the convenience of cleaning and maintenance milk powder packaging machine.

Intelligent control system: Some high-end models are equipped with touch screen control panels, which facilitate operators to adjust parameters and can integrate Internet functions to achieve remote monitoring and data management.

Selection considerations

Production capacity requirements: Select an appropriate packaging speed and output based on the production scale milk powder packaging machine.

Product features: Different materials have different fluidity, adhesion and other properties. When making a selection, these factors should be considered to match the best packaging solution milk powder packaging machine.

Packaging specifications: Different market demands may require packaging bags of different sizes and types. Therefore, equipment that can flexibly adjust packaging specifications should be selected.

Budget constraints: Balance the relationship between performance and cost based on the budget and select the equipment with the best cost performance.

With the development of technology milk powder packing, modern multi-column automatic packaging machines for milk powder have not only improved production efficiency and packaging quality, but also made considerable progress in intelligence and automation, which helps enterprises better adapt to market changes and enhance their competitiveness.