The automatic packaging machine for white sugar granules is a device used for automatic metering, filling, sealing and other packaging operations of white sugar granules sugar sachet packing machine. It is often used for small-dose and multi-column packaged white sugar products, such as sugar packets and coffee companions, with a packaging speed generally ranging from 35 to 50 cuts per minute sugar packing machine.

The multi-column packaging machine for white sugar in strip form is a specialized device designed to package white sugar into slender strip shapes and perform multi-column packaging simultaneously sugar packing machine. The following is a detailed introduction to it:

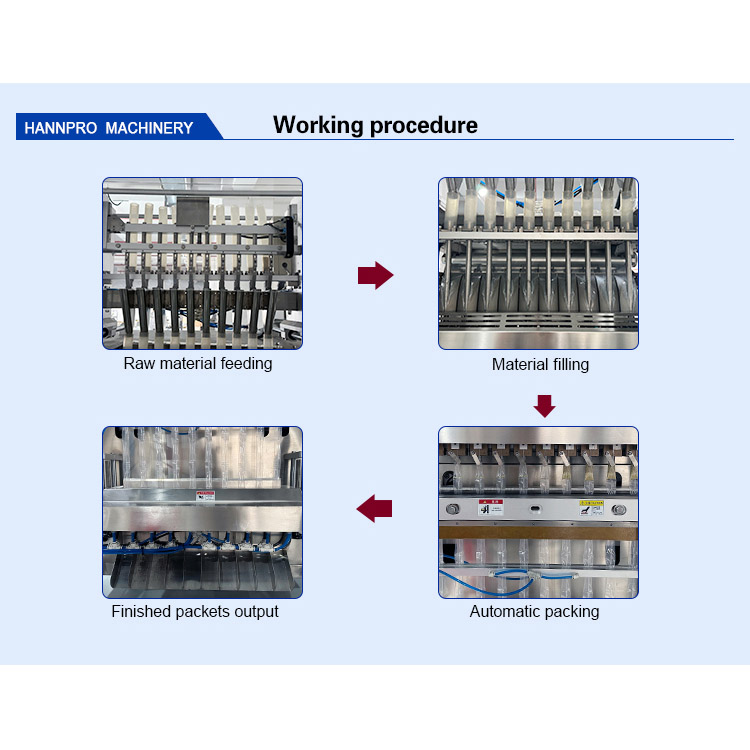

Working principle

Bag-making principle: Roll packaging films pass through a forming machine, and under the action of the longitudinal sealing device, they form a cylindrical shape sugar sachet machine. Then, they are sealed horizontally through the transverse sealing device, thereby producing multiple parallel packaging bags sugar packing machine.

The principle of metering and filling: Usually, a multi-head combination scale or a measuring cup type metering device is used to precisely measure the white sugar granules. Then, the measured white sugar granules are filled into the corresponding packaging bags respectively through the discharge channel sugar bagging machine.

The principle of sealing and cutting: The horizontal sealing device not only completes the horizontal sealing but also cuts according to the set length, dividing the continuous strip-shaped packaging bags into individual strip-shaped packaging of white sugar products. Some equipment can also perform operations such as embossing and printing at the sealing area sugar packing machine.

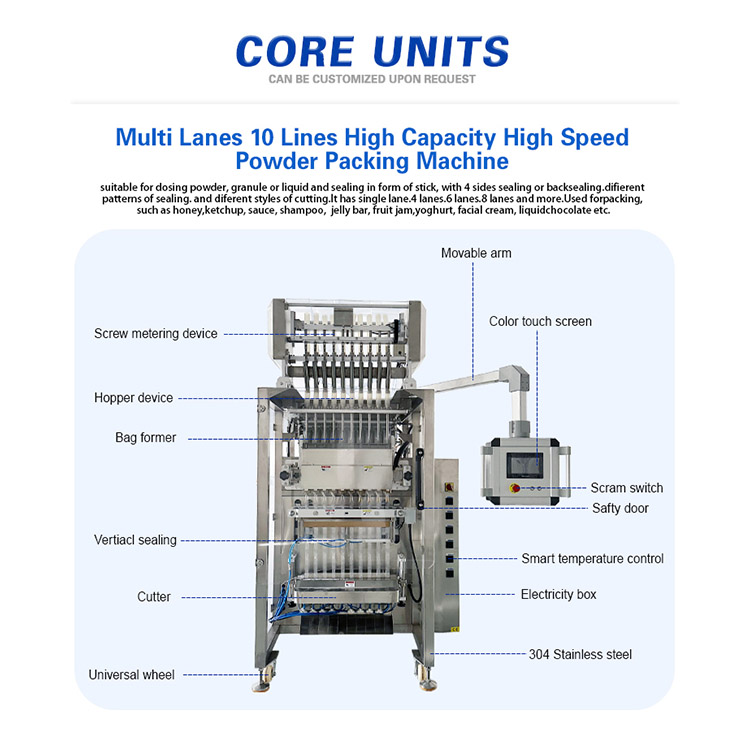

Structural composition

Film feeding mechanism: It is responsible for transporting the roll film to the packaging position. It is usually composed of motors, rollers, etc., and can achieve uniform and stable transportation of the film automatic sugar packing machine.

Measuring device: such as a multi-head combination scale, it can precisely weigh and measure white sugar, ensuring that the weight of white sugar in each package is consistent sugar packing machine.

Filling mechanism: Accurately fills the measured white sugar into the prepared packaging bags. Common ones include vibrating feeders and screw feeders, etc.

Sealing and cutting mechanism: It includes longitudinal sealing and transverse sealing devices, which are used to seal the packaging bags longitudinally and laterally and complete the cutting operation, ensuring that the white sugar in the strip packaging has good sealing performance sugar packing machine.

Control system: Generally, it is realized by using PLC (Programmable Logic Controller) in combination with a touch screen. It can set and adjust various parameters of the packaging machine, such as packaging speed, bag length, measurement accuracy, etc. It can also achieve functions such as fault alarm and automatic shutdown sugar packing machine.

Transmission system: Composed of motors, reducers, gears, chains, etc., it provides power for the operation of various mechanisms and ensures the coordinated actions among all components sugar packing machine.

Performance characteristics

High efficiency: It can package multiple strip packages simultaneously at one time, with a fast packaging speed, which can effectively improve production efficiency and meet the demands of large-scale production sugar packing machine.

High-precision measurement: Advanced metering devices are adopted, which can precisely control the filling amount of white sugar and ensure that the weight error of each package is within the allowable range.

Good packaging quality: The sealing and cutting mechanism can ensure that the sealing of the strip package is firm and smooth, and it is less likely to have sugar leakage. At the same time, it can also guarantee the accurate cutting position and the neat and beautiful appearance of the strip package.

High degree of automation: It can automatically complete a series of packaging processes such as film feeding, metering, filling, sealing and cutting, reducing manual intervention, lowering labor intensity, and improving the stability and consistency of production.

Easy operation: The control system is equipped with a human-machine interface, making parameter Settings intuitive and simple. Operators can operate it proficiently after a brief training.

Strong flexibility: By adjusting parameters or replacing some components, it can adapt to the packaging requirements of different specifications of white sugar granules and different sizes of strip packages sugar packing machine.

Maintenance and upkeep

Daily maintenance: At the end of each day's work, clean the sugar particles and dust on the surface of the equipment, check if there is any loosening or wear on each component, and promptly clear the residual materials in the metering device and the discharge channel to ensure the equipment is clean and free from blockage sugar packing machine.

Regular maintenance: Regularly lubricate the transmission components of the equipment, check the wear of the sealing and cutting tools, replace severely worn tools in time, calibrate the metering device to ensure metering accuracy, and at the same time check whether the wiring of the electrical system is firm to avoid safety hazards such as short circuits and leakage.