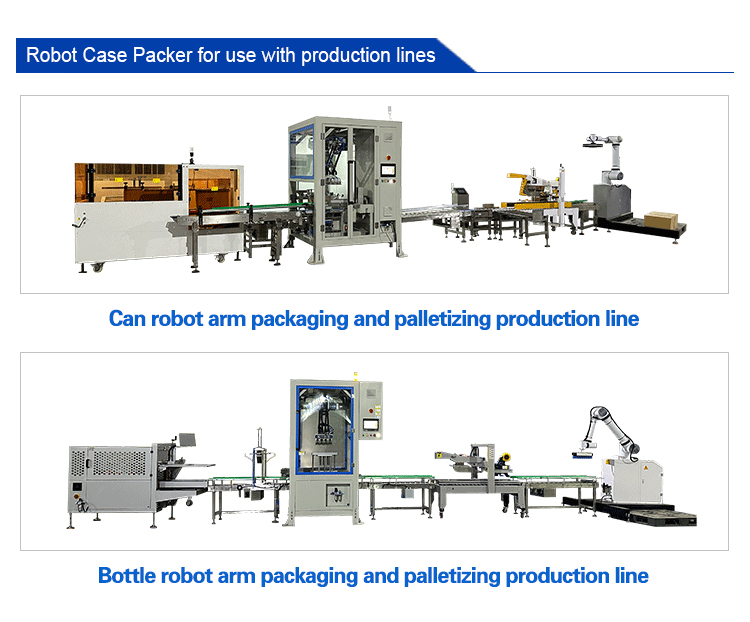

The robot case packing machine is an automated device widely used in manufacturing case packer machine, food processing, pharmaceutical production and other industries to achieve the automatic case packing operation of products.

This type of machine usually integrates advanced sensor technology, robotic arm technology and control systems, and is capable of efficiently and accurately completing various packing tasks.

Main features

High efficiency: Compared with manual packing, robot packing machines can handle a large number of products in a short time case erector and packer, improving the overall efficiency of the production line case packer machine.

High precision: Through an accurate control system and advanced sensors, it is ensured that each product can be accurately placed in the designated position case packer machine.

Flexibility: It can be adjusted according to different product types and packaging requirements, adapting to various packaging specifications and forms case packer machine.

Cost savings: Although the initial investment is large case packing, in the long run, it can significantly reduce labor costs and minimize losses caused by human errors case packer machine.

Hygiene and safety: Particularly suitable for the food and pharmaceutical industries, it reduces the opportunity for personnel to come into direct contact with products and enhances hygiene standards.

Application field

Food and beverage industry: such as packaging work for bottled water, canned food, etc.

Pharmaceutical industry: Packing and sealing operations for drugs and medical devices case packer machine.

Electronic product manufacturing: Protective packaging for fine parts or finished products robotic case packer.

Daily necessities industry: such as packaging of products like detergents and cosmetics case packer machine.

When choosing a robot cartoning machine that suits your production needs automated case packer, factors to consider include but are not limited to the size and weight of the product, production speed requirements, budget constraints, and future expansion possibilities, etc. With the development of automation technology, the functions of robot case packers will become increasingly powerful and their application scope will also be more extensive.

The control system of the robot cartoning machine is its core part, which determines the operational accuracy, efficiency and flexibility of the robot. According to different demands and levels of technological development case packer machine, the types of control systems can be classified into the following categories:

Control system based on PLC (Programmable Logic Controller) : This is one of the most common control systems and is suitable for many standard industrial automation tasks. The PLC system features high reliability and easy maintenance, and can achieve complex logical control and sequential control through programming. For some basic packing operations, such as simple grasping and placing operations, the PLC control system is sufficient to handle them.

Pc-based (Personal Computer) control system: Compared with PLC systems, PC-based control systems offer higher computing power and richer software resources. It can achieve more complex functions through advanced programming languages, such as visual recognition and path planning. This type of system is suitable for application scenarios that require processing large amounts of data or executing complex algorithms.

Specialized control system: Some high-end or specific-purpose robot case packers may adopt specially designed control systems. These systems are usually optimized for specific tasks and can provide outstanding performance. For example, some packing operations with high speed and high precision requirements may need this type of control system case packer machine.

Integrated control system: With the development of the Industry 4.0 concept, an increasing number of enterprises tend to use integrated solutions to manage the entire production line. Such a system can not only coordinate the operation of individual robot case packers, but also seamlessly integrate with other production equipment, achieving full automation and intelligence in the production process.

Intelligent control system (combined with AI technology) : In recent years, artificial intelligence technology has been widely applied in the field of industrial automation. The intelligent control system can continuously optimize the operation process through machine learning algorithms, improve work efficiency and reduce error rates. For example, by using deep learning technology to improve object recognition capabilities, robots can accurately locate and grasp items in complex environments.