The high-speed biscuit automatic packaging and boxing line is an integrated automated production line, mainly used for the high-speed packaging and boxing of biscuits and other foods cookie wrapping machine.

It can effectively improve production efficiency and product quality, and reduce labor costs cookie packaging machine. The following is its related introduction:

Component part

Biscuit conveying system: Usually composed of multiple conveyor belts, it is used to transport biscuits from the production process to the packaging and boxing area. The speed of the conveyor belt can be adjusted according to production requirements, and it has good stability and precise positioning function to ensure that the biscuits can accurately enter the subsequent packaging and boxing equipment cookie packaging machine.

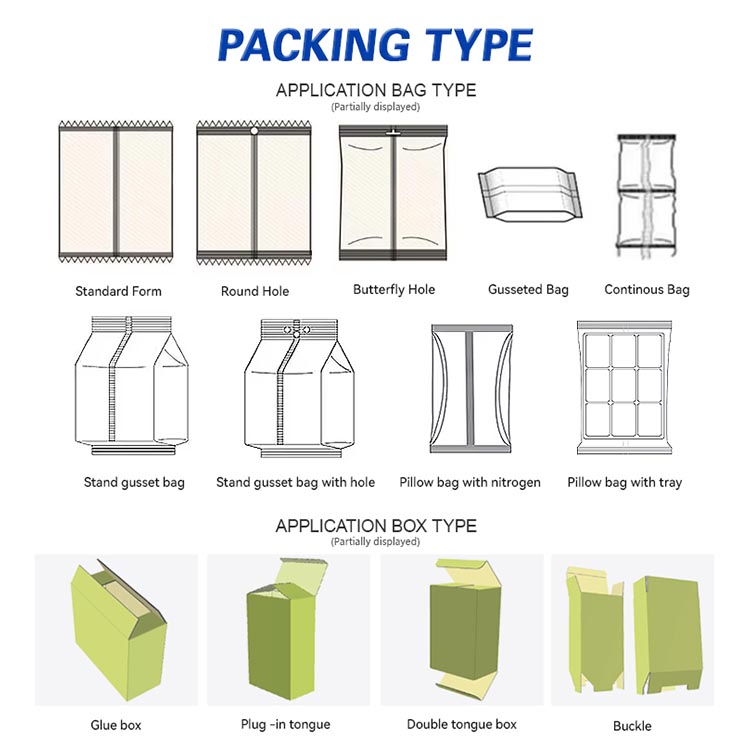

Automatic packaging machine: This is one of the core equipment of the packaging and cartoning line. Common types include pillow packaging machines and vertical packaging machines, small cookie packaging machine etc. Cookie packaging machineworking principle is to achieve single or multiple packaging of biscuits by wrapping, sealing and cutting them with packaging materials (such as plastic film) cookie wrapping machine. The automatic packaging machine features high speed and high precision, and is capable of completing the packaging of a large number of biscuits in a short period of time.

Cartoning machine: It is responsible for loading the packaged biscuits into paper boxes. Cartoning machines usually have functions such as automatic box picking, opening, filling and sealing. They can be seamlessly connected with automatic packaging machines to quickly and accurately load cookies into boxes and complete the sealing operation of the paper boxes cookie packaging machine cookie wrapping machine. Some advanced cartoning machines are also equipped with intelligent detection functions, which can automatically remove substandard cookies or cartons small cookie packaging machine.

Inkjet printer: It is used to print production date, shelf life, batch number and other information on packaged biscuits or paper boxes. The inkjet printer adopts advanced inkjet technology, which can achieve high-speed, clear and accurate inkjet effects, and can flexibly adjust the inkjet content and position according to production needs cookie packaging machine.

Robot palletizing system: The cookies packed in boxes are stacked in a certain pattern to facilitate transportation and storage. The robot palletizing system features high flexibility and accuracy. It can quickly complete palletizing tasks based on different product specifications and palletizing requirements, significantly enhancing production efficiency and warehouse space utilization cookie packaging machine.

Work process

The biscuits are conveyed to the feeding port of the automatic packaging machine by the conveyor belt. The automatic packaging machine packages the biscuits according to the preset packaging specifications and methods, wraps them in plastic film, and completes the sealing and cutting operations cookie wrapping machine.

The packaged biscuits are conveyed into the cartoning machine by the conveyor belt. The cartoning machine automatically takes out the cartons from the carton warehouse, opens the cartons and loads the biscuits into them, and then completes the sealing of the cartons.

After the cookies are packed into boxes, they pass through an inkjet printer, cookie packaging machine which prints relevant information on the cookie boxes cookie packaging equipment.

The biscuit boxes after inkjet printing are conveyed to the robot palletizing system. The robot neatly stacks the biscuit boxes on the pallets according to the preset palletizing mode. After the palletizing is completed, the pallets are conveyed to the warehouse for storage or directly transported to the shipping area.

Performance advantage

High speed and efficiency: It can achieve the packaging and boxing of dozens or even hundreds of packs of biscuits per minute, greatly improving production efficiency and meeting the demands of large-scale production cookie packaging machine.

High stability: By adopting an advanced control system and high-quality components, the equipment operates stably and reliably with a low rate of downtime due to faults, ensuring the continuous and stable operation of the production line.

Good packaging quality: The automatic packaging machine and cartoning machine have high-precision positioning and packaging functions, which can ensure that the appearance of the biscuit packaging is neat and the sealing is good. The quality of the paper box filling can also be guaranteed, reducing the damage of the product during transportation and storage cookie packaging machine.

High degree of automation: The entire production line adopts automated control, from the transportation, packaging, boxing to palletizing of biscuits, without the need for extensive human intervention individual cookie packaging machine. This not only reduces labor costs but also minimizes the impact of human factors on product quality.

Strong flexibility: According to different types, specifications and packaging requirements of biscuits, the operation parameters and packaging methods of the production line can be quickly adjusted through simple parameter Settings and mold changes, adapting to diverse production needs cookie packaging machine.

Maintenance and Management

Daily maintenance: including cleaning, lubrication, tightening and other tasks of the equipment. Regularly clean the surface and interior of the equipment from biscuit debris, dust and other debris, lubricate the moving parts such as conveyor belts, chains and gears, and check whether the connecting bolts of each part are loose to ensure the normal operation of the equipment.

Regular maintenance: Conduct a comprehensive inspection and maintenance of the equipment at regular intervals, replace severely worn parts individual cookie packaging machine, and test and debug the electrical system and control system to ensure the performance and accuracy of the equipment cookie packaging machine.

Personnel training: Operators need to undergo professional training, be familiar with the operation process and maintenance knowledge of the equipment, be able to operate the equipment correctly, and promptly identify and solve problems that occur during the operation of the equipment cookie packaging machine.

Production management: Establish a complete production management system, rationally arrange production plans, conduct real-time monitoring and recording of equipment operation status and production data, so as to promptly adjust production strategies, improve production efficiency and product quality.