A palletizer is an automated device that can automatically stack packaged goods (cartons) into piles according to a specific pattern.

It is widely used in industries such as food, beverages, chemicals, logistics, and warehousing. By replacing manual palletizing, it significantly improves production efficiency, reduces labor intensity, and ensures the stability and consistency of palletizing.

Core Functions of the Palletizing Machine

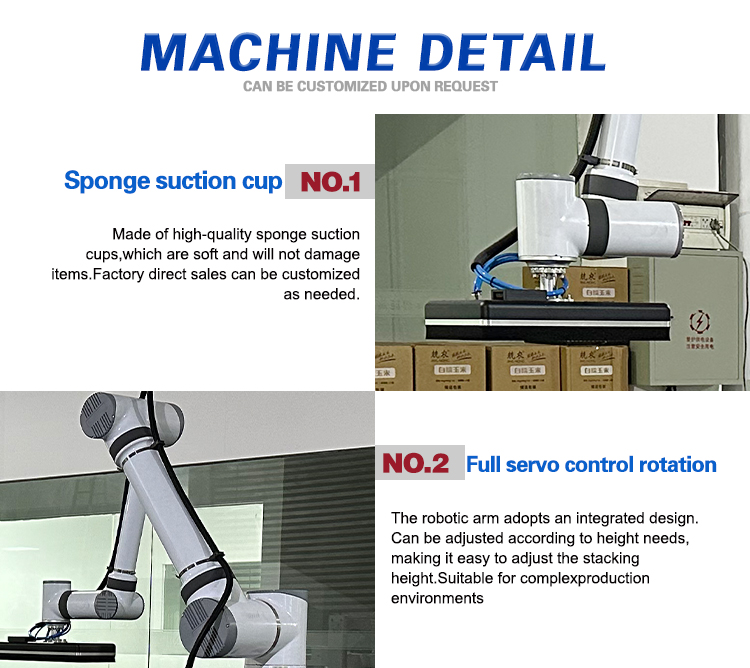

1. Automatic Gripping: Precisely grips goods on the conveyor belt using suction cups or similar devices.

2. Positioning and Stacking: Stacks goods in an orderly manner on pallets or designated locations according to pre-set stacking patterns (e.g., rectangular, triangular, interlocking, etc.).

3. Intelligent Adjustment: Automatically adjusts gripping force, stacking speed, and stacking pattern structure based on cargo parameters such as size, weight, and material.

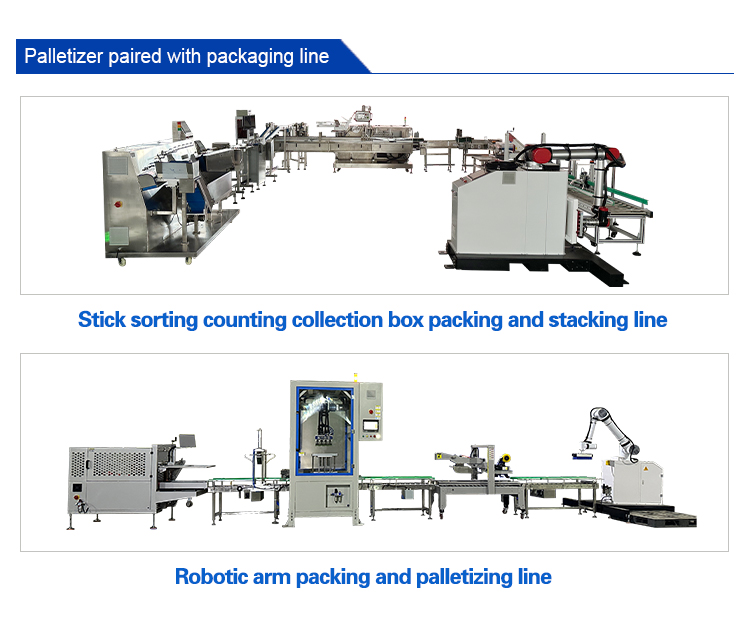

4. Continuous Operation: Integrates with production lines to enable unmanned continuous operation, reducing human intervention and enhancing the overall automation level of the production process.

Structural features: Consists of a multi-joint robotic arm with an end effector (suction cup), offering high flexibility.

Advantages:

Wide range of applications, capable of handling cartons of different shapes and sizes.

Small footprint, capable of operating in confined spaces.

Flexible programming, supporting quick switching between pallet types and production tasks.

Applicable scenarios: Multi-variety, small-batch production, or scenarios requiring the handling of irregularly shaped goods.

Structural features: Consists of a multi-joint robotic arm with an end effector (suction cup), offering high flexibility.

Advantages:

Wide range of applications, capable of handling cartons of different shapes and sizes.

Small footprint, capable of operating in confined spaces.

Flexible programming, supporting quick switching between pallet types and production tasks.

Applicable scenarios: Multi-variety, small-batch production, or scenarios requiring the handling of irregularly shaped goods.

Advantages of Palletizing Machines

Improved Production Efficiency: Replacing manual palletizing, these machines can operate continuously for 24 hours, achieving stacking speeds of dozens or even hundreds of times per minute, far exceeding manual efficiency.

Reduced Labor Costs: Reducing the need for manual labor lowers long-term labor costs, particularly suitable for palletizing positions with high repetition and high labor intensity.

Improved Palletizing Quality: Through precise control, pallets are stacked neatly and securely, reducing the risk of cargo collapse and facilitating storage and transportation.

Enhanced Production Safety: Avoids safety incidents such as collisions and compression during manual handling, particularly suitable for handling heavy or hazardous goods.

Flexible Production Support: Enables quick switching of pallet configurations and production tasks through programming, adapting to market demand changes for multiple product varieties and small batch sizes.