The horizontal cartoning machine is an automated device widely used in the pharmaceutical, food, cosmetics and other industries cartoning machines.

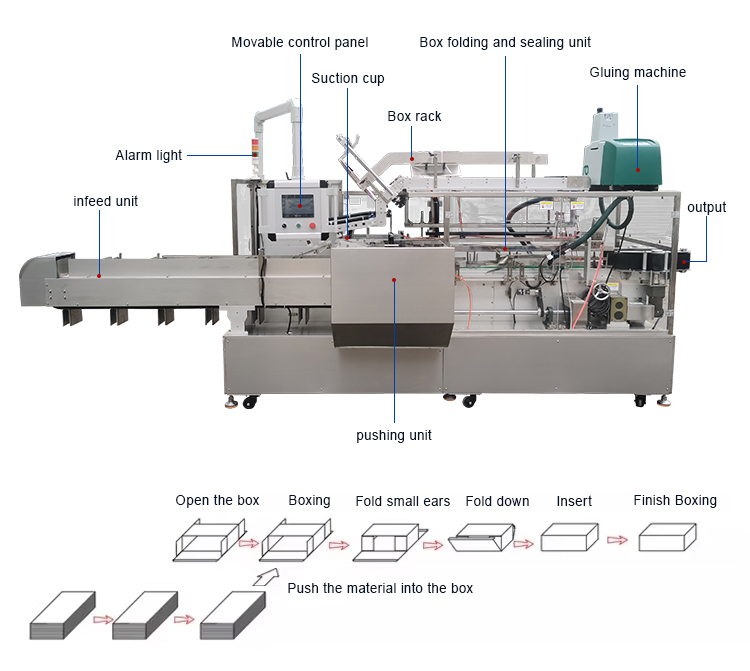

It is mainly used to automatically load products into paper boxes and complete the sealing actions. This kind of machine is usually suitable for packaging products of different shapes such as bottles, boxes or bags. The working principle of the horizontal cartoning machine is to send the products to the cartoning position through a conveyor belt, and then use push rods or other devices to push the products into the open paper boxes. After that, operations such as folding and sealing are carried out.

The main features of the horizontal cartoning machine include cartoner

High degree of automation: It can achieve a fully automated process from opening the paper box to final sealing.

Wide application range: Capable of handling various types and sizes of products cartoning machines.

Convenient adjustment: For products and paper boxes of different specifications, simple adjustments are sufficient to meet production requirements.

High efficiency and stability: It features high production efficiency and stability automatic box folding and taping machine, reducing the possibility of errors caused by manual intervention cartoning machines.

When choosing a horizontal cartoning machine, it is necessary to determine the appropriate model and configuration based on factors such as the product's characteristics (such as size, weight, shape, etc.), production speed requirements, and budget. In addition, it is also very important to consider maintenance and service support to ensure the long-term stable operation of the machine cartoning machines.

When choosing the specification and model of a horizontal cartoning machine, the following key factors should be comprehensively considered horizontal cartoner:

Product features: First, it is necessary to clarify the specific information of the product to be packaged, including but not limited to the size, weight, shape, etc. of the product. Different products may require different types of cartoning machines to meet their unique packaging needs cartoning machines.

Production speed: Determine the working efficiency of the cartoning machine based on the demands of the production line. This is usually measured by the number of boxes that can be processed per minute (that is, "speed"). Ensure that the speed of the selected equipment matches the overall production capacity of the production line cartoning machines.

The size and type of the paper box: Consider the size range (length, width, and height) of the paper box to be used, the material, and whether there are any special design requirements (such as Windows or partitions). Some advanced cartoning machines can automatically adjust to fit cartons of various sizes, while others may require manual adjustment cartoning machines.

Degree of automation: Decide whether to choose a fully automatic or semi-automatic cartoning machine based on the budget and production requirements. The fully automatic cartoning machine can achieve a fully automated process from opening the box to sealing it, reducing manual intervention. However, semi-automatic cartoning machines may still require manual operation in some steps.

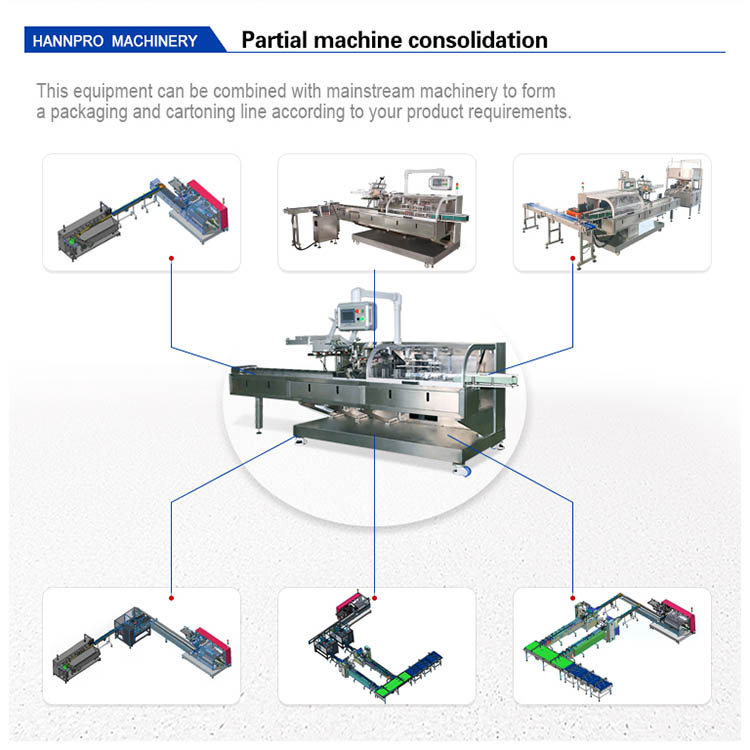

Compatibility and flexibility: Considering possible future changes, such as the addition of new product lines or the modification of existing ones, it is very important to choose machines with good compatibility and flexibility. Ideally, the machine should be able to be adjusted easily to meet the new packaging requirements cartoning machines.

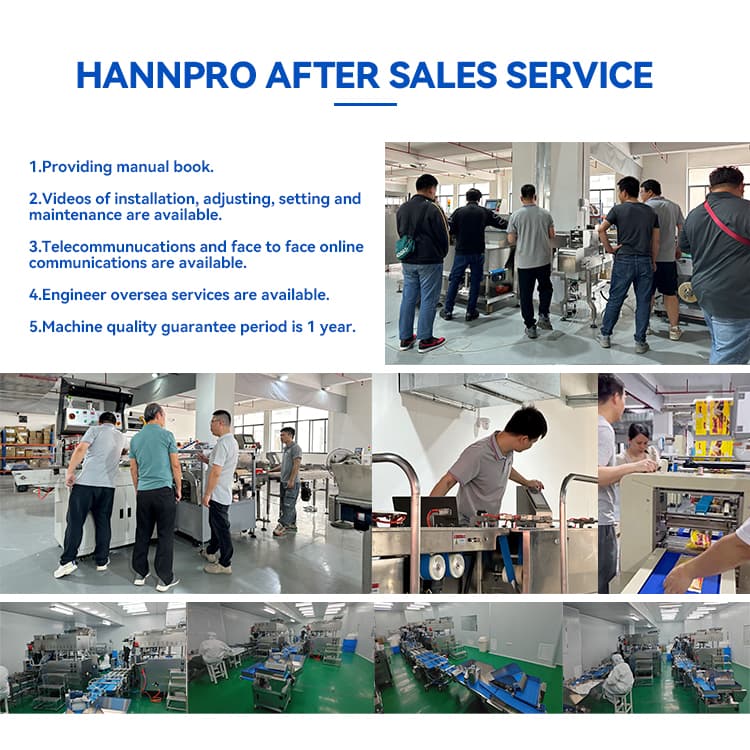

Maintenance and service support: It is very important to choose a brand that offers good after-sales service and technical support. Find out whether the supplier provides timely maintenance services, parts supply and training courses, etc.

Cost-benefit analysis: Last but not least cardboard box machine, conduct a comprehensive cost-benefit analysis. In addition to the purchase price, factors such as operating costs, maintenance expenses, and energy consumption also need to be taken into account to ensure that the return on investment meets expectations.

By carefully evaluating all the above aspects, it can help you make a wiser choice and find the horizontal cartoning machine that best suits your business needs.