The automatic sorting and feeding machine using to separate the mix products into one pcs by one pcs come. can adopt with count function sorting machine, to adopt with the multic package machine, cartoning machine or other machine

Machine application products:

It is applicable to food, daily necessities, chemicals, medicine, hardware and other industries sorting machine. For example: Supplement powder sticks,solid drinks sachets, granule sachets and other sticks, sachets and square shape packaging products sorting machine.

Machine detail:

Storage hopper:food-grade material, large capacity, can input a large amount of products at one time, saving labor time, efficient.

Lifting unit:products are lifted at a constant speed to avoid excessive stacking of products , and the speed can be adjusted according to production capacity requirements.

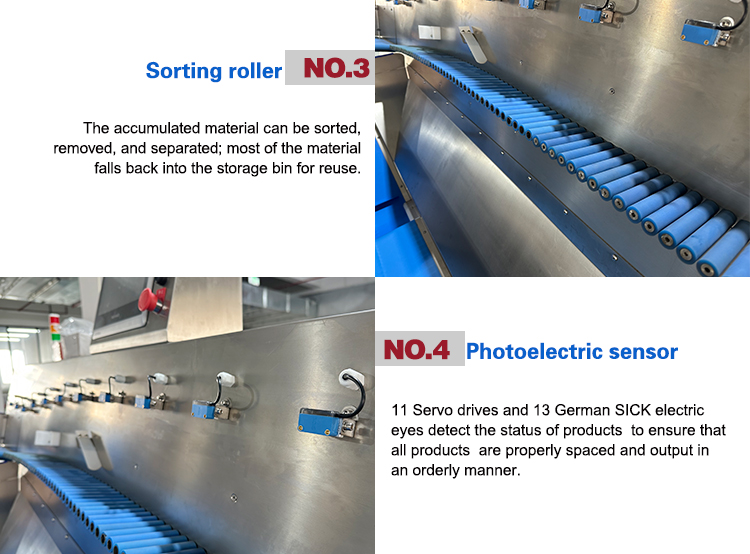

3.Sorting roller:The accumulated material can be sorted, removed, and separated; most of the material falls back into the storage bin for reuse sorting machine.

4.Photoelectric sensor:11 Servo drives and 13 German SICK electric eyes detect the status of products to ensure that all products are properly spaced and output in an orderly manner sorting machine.

5.Guidance block:Can perform the first stage of compression and blocking, performing the initial processing of stacked packages.

6.Control panel:The high-definition large-screen touch screen integrates all parameters into one screen for adjustment.

7.Alarm light:Foldable design, three colors: red, yellow andgreen, red indicates abnormal conditions and analarm sounds, yellow indicates power-on statusgreen indicates normal operation.

High-speed and efficient: Operates at high speeds to meet the demands of large-scale production. For example, the DXHL10 Multi-Dimensional Sorting System (AI Edition) achieves a processing speed exceeding 200 bags per minute, while its optional DXHL10F Ball Divider unit can reach an efficiency of 600–1,500 bags per minute sachets sorting packing machine.

Highly Intelligent: Utilizes dedicated AI control processors, intelligent algorithms, and multi-axis servo control systems to automatically perform functions such as equipment changeover adjustments and fault diagnosis. New product integration requires no programming, ensuring user-friendly operation sachets sorting packing machine.

High sorting accuracy: Utilizing servo motor drive, continuous low-noise gear transmission technology, and real-time monitoring feedback from photoelectric sensors, the system precisely controls bag conveying speed and position, ensuring sorting accuracy and stability. The rate of stacked or consecutive bags can be kept below 0.1%.

Energy-efficient and environmentally friendly: Some sorting machines adopt a hybrid servo system with energy recovery functionality, reducing equipment energy consumption.

Easy maintenance: The modular design facilitates maintenance and servicing, with limited fault areas for easy troubleshooting. Some bag sorting machines also feature quick maintenance functions, such as two-minute quick maintenance, which reduces equipment downtime and improves production efficiency.