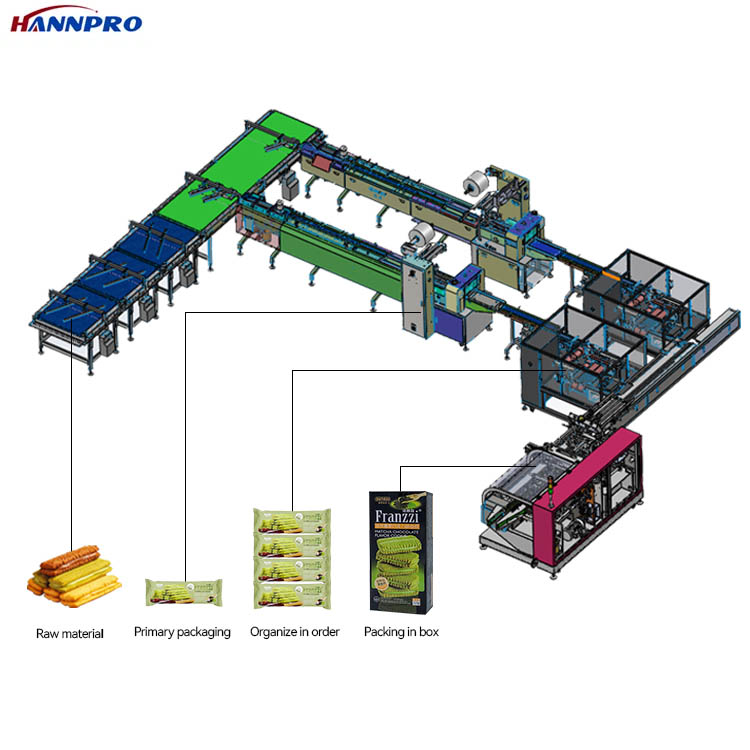

In today's highly competitive biscuit market, high-efficiency and high-quality production lines have become the key factor for enterprises to win Automatic Biscuit Packing Line. Modern biscuit production lines integrate multiple automated devices, achieving full-process automated operation from packaging to boxing. This article will delve into the key equipment and their working processes in the biscuit production line, including the automatic pillow packaging machine, the material sorting system, the biscuit cartoning machine, the paper box spray glue sealing machine and the automatic case packing machine.

Automatic pillow packaging machine

The automatic pillow packaging machine is the first process of biscuit packaging. Its features include:

- High-speed packaging: Advanced pillow packaging machines can achieve a speed of 100 packages per minute Automatic Biscuit Packing Line.

- Versatility: Capable of handling cookies of various shapes and sizes, adapting to different packaging requirements Cookies Packing Line.

- Intelligent control: Equipped with a PLC control system, it can precisely adjust packaging parameters to ensure consistent weight for each package Automatic Biscuit Packing Line.

Modified atmosphere packaging: An optional modified atmosphere system is available to extend the shelf life of cookies.

2. Material sorting system

The material handling system is the key link connecting the packaging and cartoning processes Automatic Biscuit Packing Line. Its functions include:

- Organizing and arranging: Arrange the scattered cookie packages in an orderly manner to prepare for subsequent boxing Cookies Packing Line.

- Inspection and rejection: Equipped with a visual inspection system, it automatically rejects substandard packaging.

- Counting and grouping: According to the packaging requirements, group the biscuit packs to ensure the accuracy of the quantity in each box Automatic Biscuit Packing Line.

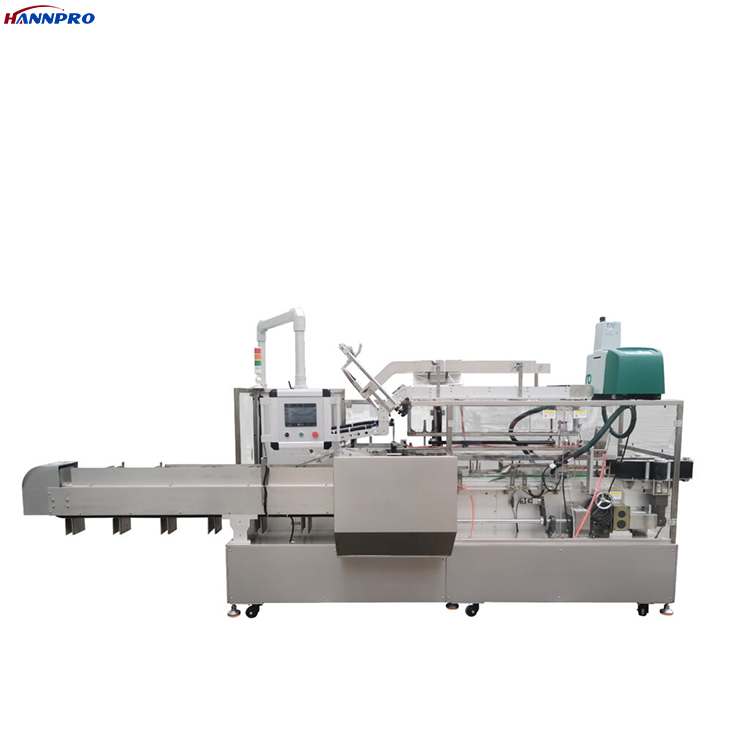

3. Biscuit cartoning machine

As the core equipment of the production line, the biscuit cartoning machine has the following features:

- Multi-specification adaptation: Can be quickly adjusted to fit biscuit packs and cartons of different sizes Automatic Biscuit Packing Line.

Intelligent control: Equipped with a touch screen interface, it is easy to operate and can monitor the production status in real time Automatic Biscuit Packing Line.

4. Paper box spray glue sealing machine

The paper box spray glue sealing machine is a key equipment to ensure the integrity of packaging:

- Precise glue spraying: A high-precision glue spraying system is adopted to ensure an appropriate amount of glue and a firm bond Automatic Biscuit Packing Line.

- Multi-point glue spraying: Multiple glue spraying points can be set according to the structure of the paper box to enhance the reliability of box sealing.

- Hot melt adhesive technology: Utilizing environmentally friendly hot melt adhesive, it features fast drying speed and high strength Automatic Biscuit Packing Line.

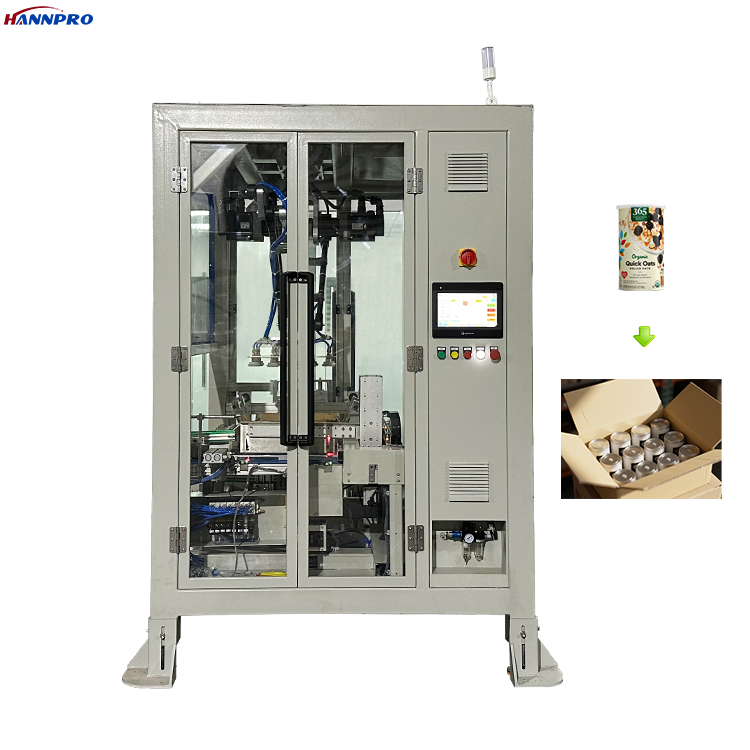

5. Automatic case packing machine

As the final process of the production line, the automatic cartoning machine has the following characteristics:

- Efficient case packing: Advanced case packers can achieve a speed of 15 to 20 cases per minute.

- Flexible configuration: The packing method and quantity can be adjusted according to different products Automatic Biscuit Packing Line.

- Automatic box sealing: Integrated box sealing function to complete the final packaging processing.

The advantages of bagged biscuit production lines

1. Enhance production efficiency: The fully automated process significantly boosts production capacity and reduces labor costs.

2. Ensure product quality: Precise control and detection systems guarantee the quality of products at every stage Automatic Biscuit Packing Line.

3. Reduce waste: Precise measurement and packaging systems minimize raw material waste to the greatest extent.

4. Enhance hygiene standards: Reduce manual contact and improve the hygiene level of the production process Automatic Biscuit Packing Line.

5. Enhance flexibility: Quickly switch between different product specifications to meet diverse market demands Automatic Biscuit Packing Line.

The modern biscuit automated production line, from automatic pillow packaging, material arrangement, box filling, box sealing to final boxing, constitutes an efficient and precise production system. This full-process automation not only significantly enhances production efficiency but also ensures the consistency of product quality, giving biscuit manufacturers an edge in the fierce market competition.

For biscuit manufacturing enterprises, introducing advanced automated production lines will become a key factor in maintaining competitiveness in the future market. Choosing the right equipment supplier, such as Yishang Machinery, which has extensive experience in non-standard complete lines in the packaging machinery field, can provide enterprises with comprehensive technical support and solutions, helping them achieve a dual improvement in production efficiency and product quality.