The Popsicle pack automatic packaging machine is an automated device specifically designed for efficient and hygienic packaging of frozen foods such as popsicles and ice cream Water Sachet Packing Machine. This type of machine can significantly enhance production efficiency and ensure the quality and safety of products during the packaging process Water Stick Packing Machine. The following is some detailed information about the automatic packaging machine for Popsicle sticks:

Main features

Wide applicability: It is not only suitable for popsicles but also for packaging other frozen foods of similar shapes Water Sachet Packing Machine.

High efficiency: It features a high packaging speed, typically capable of completing dozens to hundreds of packages per minute, depending on the model and packaging specifications Water Stick Packing Machine.

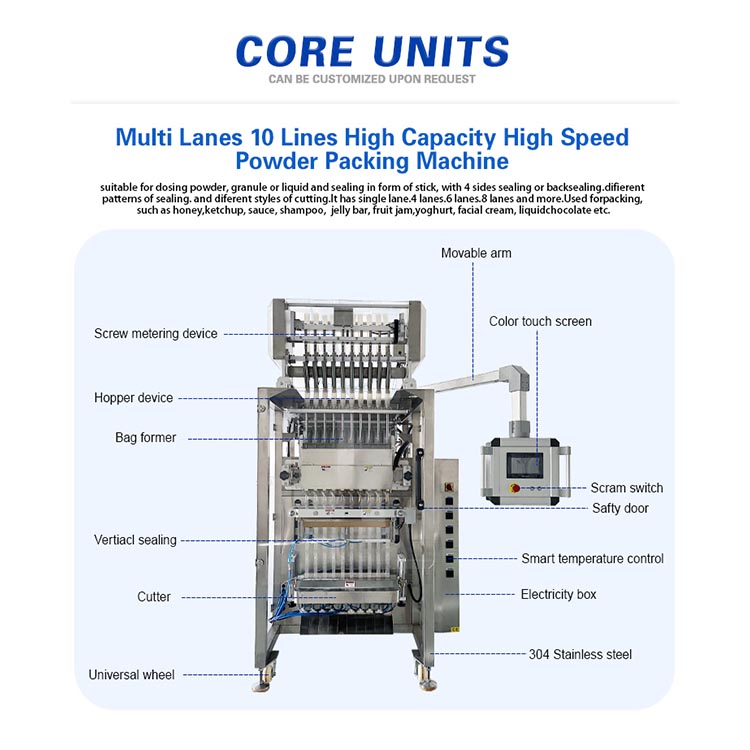

High degree of automation

It automatically completes a series of operations from feeding materials, bag making, filling to sealing and cutting Water Sachet Packing Machine.

Equipped with a PLC control system and a touch screen interface, it is convenient for parameter setting and monitoring Water Packing Machine.

Strong material adaptability: Supports transparent or colored packaging films of various materials such as PE, PVC, and PP.

Sanitary design

Made of stainless steel, it is easy to clean and disinfect, and meets food safety standards Water Sachet Packing Machine.

The design takes into account dust-proof and water-proof functions to ensure food hygiene Water Packing Machine.

Multi-functional configuration

An optional coding machine can be equipped to print information such as production date and batch number on the packaging.

It supports an easy-to-tear opening design, which is convenient for consumers to use Water Sachet Packing Machine.

Precise control: Through the servo motor drive system, precise position control and speed adjustment are achieved to ensure packaging quality and consistency.

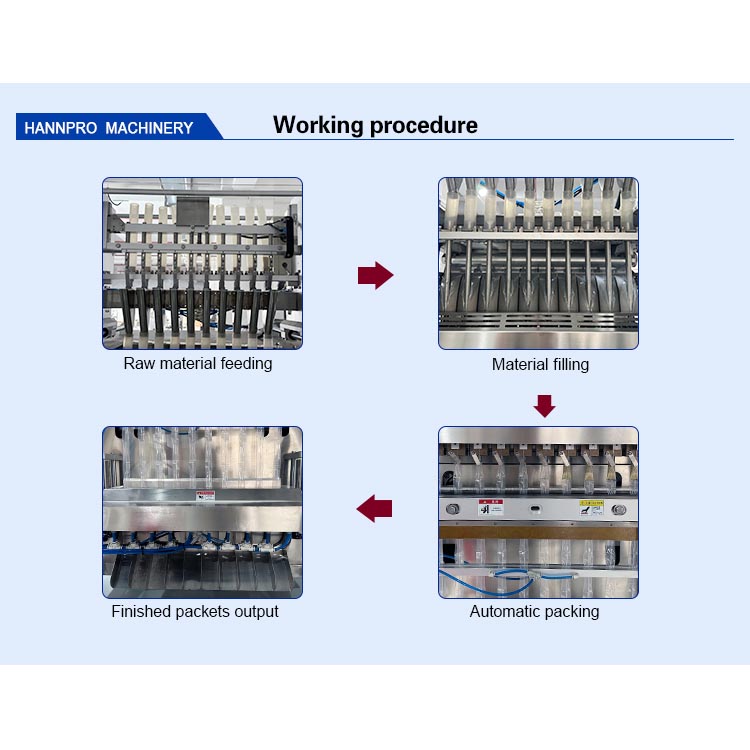

Overview of the Workflow

Supply preparation: Place the popsicles to be packaged on the conveyor belt and get them ready for the packaging process.

Bag forming: The packaging film forms a tubular structure through the forming machine and is longitudinally sealed by the longitudinal sealing mechanism.

Popsicle filling: Popsicles are placed one by one into the already made bags Water Sachet Packing Machine.

Sealing and cutting: Apply horizontal heat sealing at both ends of each bag and combine the cutting to form independent small packages.

Finished product output: The packaged popsicles are sent out through a conveyor belt, ready for the next processing step or directly stored in the warehouse Water Sachet Packing Machine.

Purchasing suggestions

Production capacity: Select an appropriate packaging speed based on the daily output requirements of the enterprise Water Sachet Packing Machine.

Packaging specifications: Consider whether it is necessary to frequently change packaging bags of different sizes and the machine's capability in this regard.

Compatibility: Confirm whether the selected equipment can handle the specific type of packaging materials you plan to use Water Sachet Packing Machine.

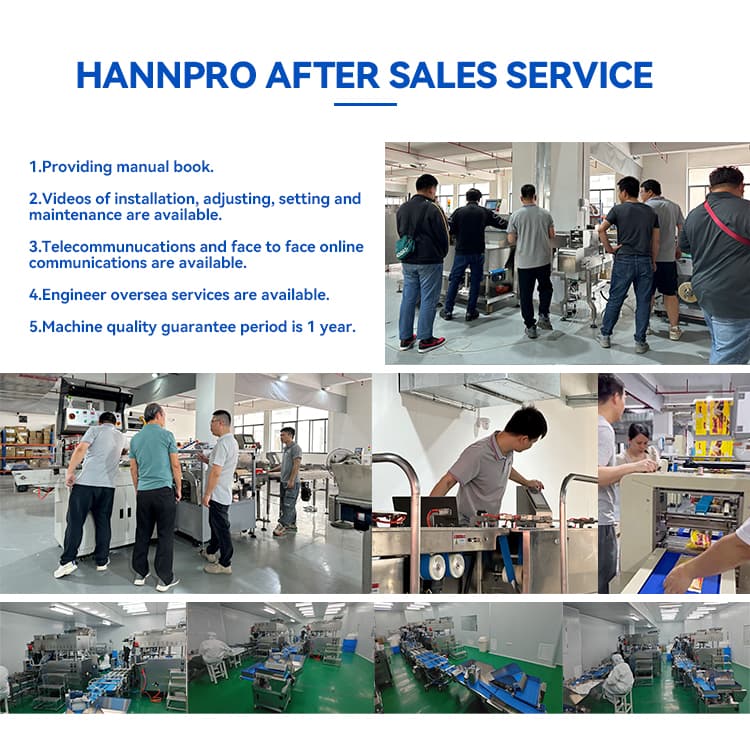

After-sales service: Understand the installation and commissioning, training and guidance, as well as subsequent maintenance services provided by the supplier.

With the changes in market demand and the development of technology, modern automatic packaging machines for Popsicle sticks are increasingly trending towards intelligence and modularization, which makes them easier to operate and maintain. If you are looking for an automatic Popsicle stick packaging machine that suits your business, it is recommended that you contact a professional manufacturer or seller to obtain the latest product information and technical support. At the same time, considering the special properties of popsicles (such as low-temperature requirements), it is also very important to ensure that the packaging machine can operate stably in a suitable temperature environment.