The collaborative palletizer robot is a device that automatically stacks bags, cartons or other packaging materials sent by the conveyor into pallets according to the working method required by the customer's process, and transports the palletized materials. Realize intelligent operation management, simple and easy to master. It can greatly reduce labor force and reduce labor intensity.

SmartHP01

Palletizing Robot Machine

Efficient handling and stacking into stacks

Machine detail

Ⅰ.Modular suction cup

Applicable to a variety of different types of products.A variety of suitable fixtures can be replaced.High-precision grasping capability.Realize the handling and palletizing of items.

Ⅱ.Full servo control rotation

The robotic arm adopts an integrated design,Can be adjusted according to height needs,making it easy to adjust the stackingheight.Suitable for complexproductionenvironments.

Ⅲ.Smart Touch Screen design

PLC control, high-definition smart touchscreen, graphical visual interface, easy tolearn.

Ⅳ.Roller conveying system

Automatically transfer the boxto the grasping position.Robots accurately identifyand efficiently stack.

Core Functions of the Palletizing Machine

1. Material Handling and Transportation: Using mechanical gripper suction cup actuators, the machine precisely picks up materials from the conveyor line and transports them to the palletizing area along a predefined path.

2. Automatic Palletizing Arrangement: Based on material parameters such as shape, size, and weight, materials are stacked layer by layer into stable pallet structures according to predefined pallet patterns (e.g., rectangular pallets, pyramid pallets, interlocking pallets, etc.).

3. Pallet Pattern Adjustment and Optimization: The palletizer features adaptive adjustment functionality, enabling real-time adjustment of gripping and stacking strategies based on the actual condition of the materials (e.g., minor deformation, positional deviation) to ensure pallet stability.

4. Continuous Operation and Integration: Seamlessly integrates with upstream production lines (e.g., packaging machines, conveyors) and downstream equipment (e.g., wrapping machines, forklifts) to achieve fully automated material handling from packaging completion through palletizing, wrapping, and storage.

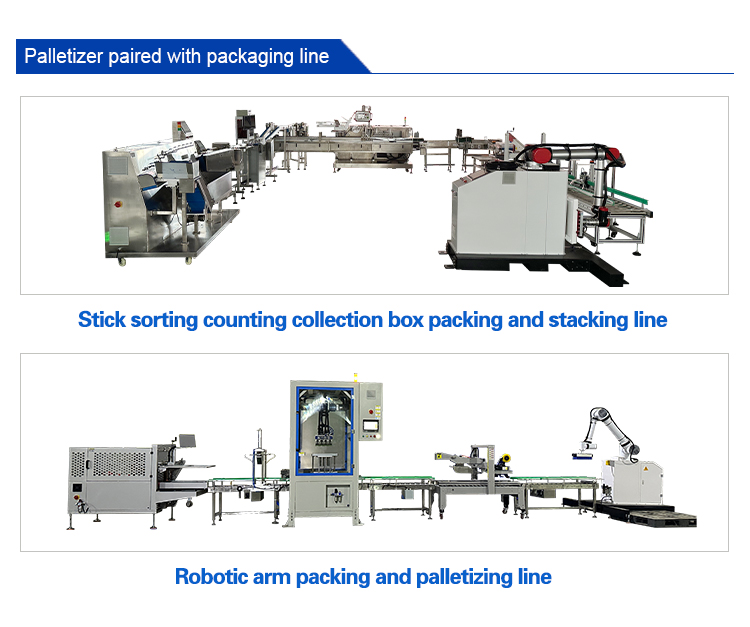

Palletizers are integrated with other machines to form a complete packaging line.

Advantages of Palletizing Machines

1. Improved Production Efficiency: Replacing manual palletizing with high-speed continuous operation, a single palletizing machine can complete hundreds to thousands of palletizing actions per hour, far exceeding manual efficiency.

2. Improved Palletizing Quality: Through precise mechanical control, materials are stacked neatly and securely, reducing the risk of damage or collapse, and minimizing losses during storage and transportation.

3. Reduced Labor Costs: Reduces reliance on manual labor, particularly suitable for repetitive and physically demanding palletizing tasks, while eliminating errors and safety hazards associated with manual operations.

4. Enhance production flexibility: Through programming, quickly switch between different pallet types and material specifications to adapt to diverse product varieties and small batch production demands, enhancing the flexibility and adaptability of production lines.

5. Improve working conditions: Operate stably in harsh environments such as dust, noise, and low temperatures, protecting the health of operators.