The automatic packaging machine for sugar granule strips is a specialized automated device designed to separate sugar granules (such as granulated sugar, brown sugar, rock sugar, etc.) into small bags in the form of strips according to the predetermined quantity or weight Sugar Sachet Packing Machine. This type of packaging machine is highly suitable for candy manufacturing enterprises and those that need to quantitatively package sugar products. It can significantly enhance production efficiency and packaging quality.

The main features of the automatic packaging machine for sugar granule strip packaging:

High-precision measurement: Advanced electronic weighing technology or volumetric metering devices are adopted to ensure that the weight of each packet of sugar is consistent with minimal error Sugar Sachet Packing Machine.

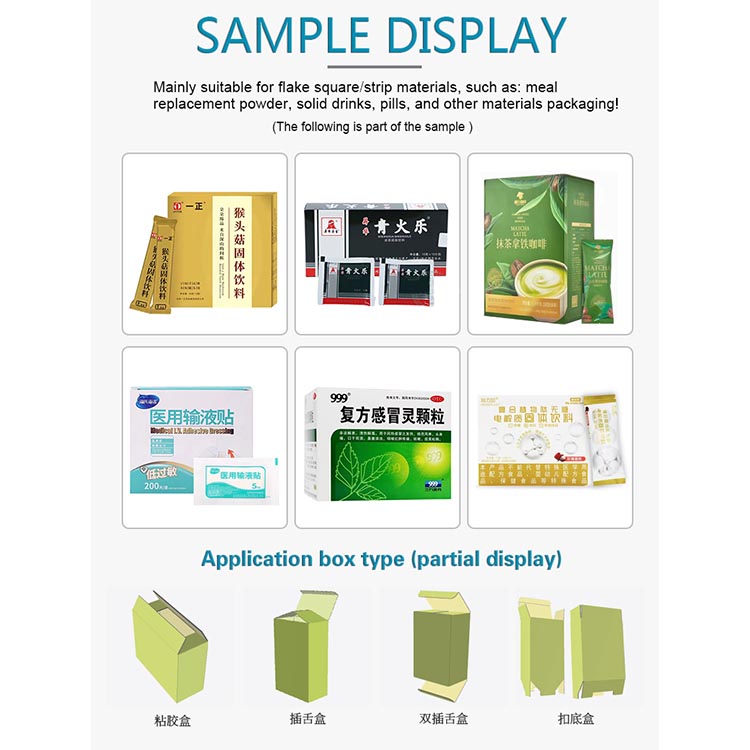

Versatility: It is not only suitable for packaging sugar granules, but also can be used for small granular materials with similar physical properties, such as salt, monosodium glutamate, coffee beans, etc Sugar Packing Machine.

Fast and efficient: The packaging speed is relatively fast, usually ranging from dozens to hundreds of packages per minute, depending on the model and packaging specifications Sugar Sachet Packing Machine.

High degree of automation

It automatically completes a series of operations from feeding materials, metering, bag making, sealing to cutting Sugar Sachet Packing Machine.

Equipped with a touch screen control system, users can easily set parameters and monitor the operating status through the interface Sugar Packing Machine.

Adaptability to multiple packaging materials: Supports various types of films such as PE, PP, and composite films as packaging materials Sugar Sachet Packing Machine.

Safety and hygiene design: The whole machine is made of food-grade stainless steel, which is easy to clean and maintain. It also has dust-proof and moisture-proof functions to ensure food safety.

Optional devices: including coding machine, easy-tear opening device, metal detector, etc., further enhance the added value and safety of the product Sugar Sachet Packing Machine.

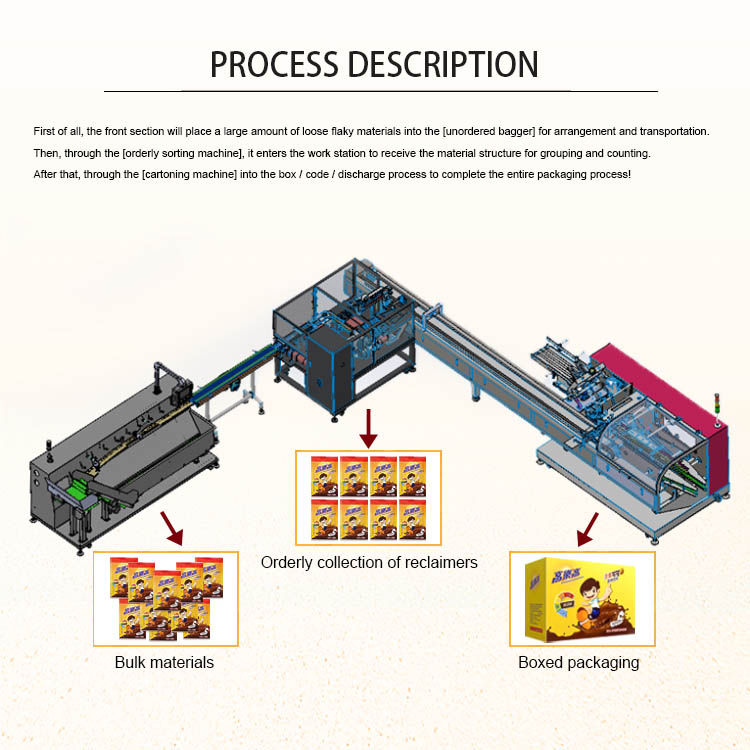

Brief description of the work process:

Feeding: Sugar granules are evenly fed into the metering system through a vibrating disc or other feeding devices.

Measurement: Precisely measure the required product quantity based on the preset weight or quantity Sugar Sachet Packing Machine.

Bag-making: After the packaging film is formed into a tube by the forming machine, it is longitudinally heat-sealed by the longitudinal sealing mechanism Sugar Stick Packing Machine.

Filling: The measured sugar granules are automatically poured into the already made bags Sugar Sachet Packing Machine.

Horizontal sealing and cutting: Perform horizontal heat sealing and cutting at both ends of each bag to form independent small packages.

Output finished product: Finally, the packaged sugar granule strip packages are output through the conveyor belt Sugar Stick Packing Machine.

Purchasing notes:

Capacity demand: Select an appropriate packaging speed based on the daily output requirements of the enterprise Sugar Sachet Packing Machine.

Packaging specifications: Consider whether it is necessary to frequently change packaging bags of different sizes and the machine's capability in this regard.

Compatibility: Confirm whether the selected equipment can handle the type of packaging material you plan to use.

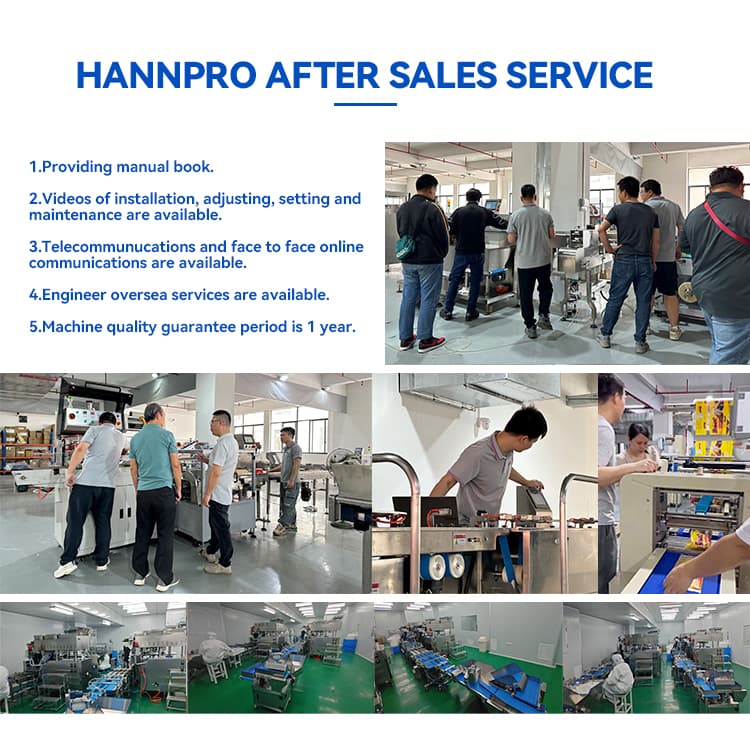

After-sales service: Understand the installation and commissioning, training and guidance, and subsequent maintenance services provided by the supplier Sugar Sachet Packing Machine.

In conclusion, the automatic packaging machine for sugar granule and strip packaging provides an efficient, accurate and economical solution for sugar product enterprises, which is conducive to enhancing market competitiveness. If you are looking for such equipment, it is recommended that you contact a professional manufacturer or seller to obtain more detailed technical data and quotation information.