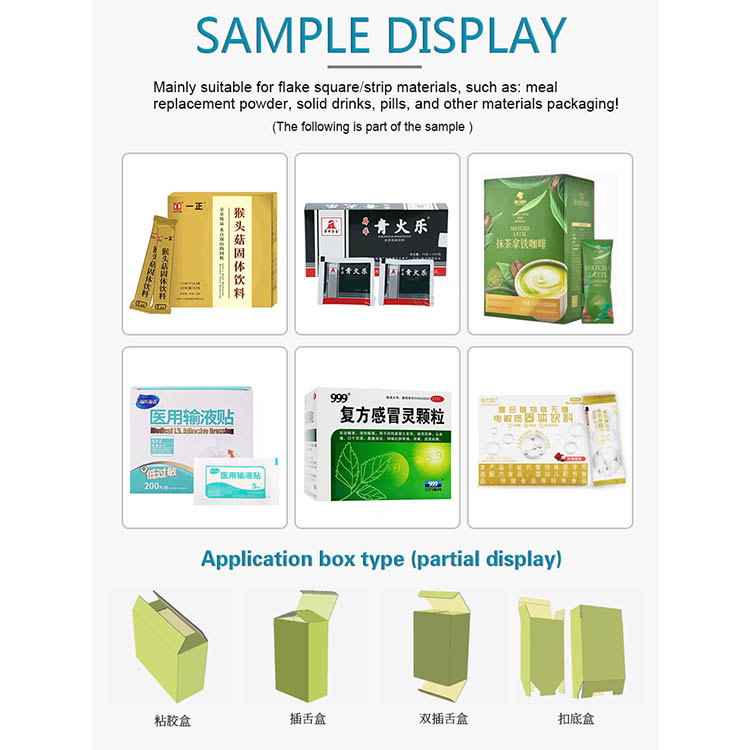

The strip packaging machine is an automated device used for strip packaging of products and is widely applied in industries such as food, medicine, daily chemicals, and electronics Stick Packaging Line. It can arrange products in a certain quantity into strips and encapsulate them with films (such as PVC, PO, PP, etc.) or paper boxes to form independent small packaging units, which is convenient for transportation, storage and sales.

I. Main Functions of the bag assembly:

Automatic counting and arrangement: Automatically arrange the products into strips according to the set quantity.

Automatic film supply and sealing and cutting: Automatically supply packaging film and complete operations such as longitudinal sealing, transverse sealing, and cutting Stick Packing Line.

Heat sealing molding: The packaging film is sealed through a heating system Stick Packaging Line.

Automatic discharging: The finished products are automatically output after packaging is completed Stick Packaging Line.

Optional functions:

Coding/spray coding

Automatically remove defective products

Switching among multiple specifications

PLC control + touch screen operation interface

Ii. Common Types:

Pillow strip baling machine

The packaging shape is a pillow-shaped bag

It is suitable for regular small items such as candies, batteries, chewing gum, etc Stick Packaging Line

Vertical strip wrapping machine

Bag-making in the vertical direction is suitable for granular and powdered products Stick Packaging Line

Horizontal strapping machine

Horizontal film feeding for bag making is suitable for long and strip-shaped products such as toothbrushes, cards, stationery, etc Stick Packaging Line

Combined strapping machine

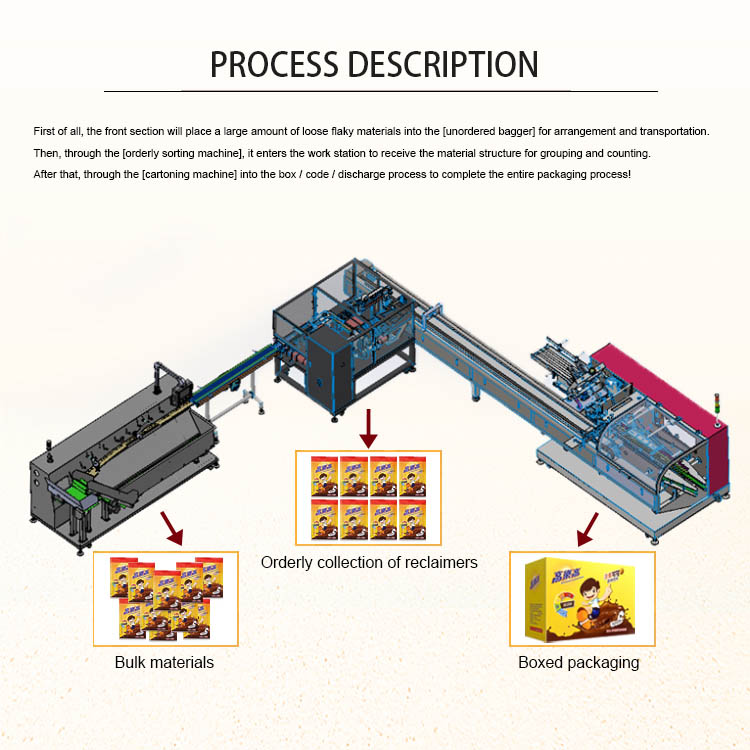

It can be used in conjunction with other packaging equipment, such as cartoning machines and labeling machines

The multi-specification switching of the strip packaging machine is mainly to adapt to the packaging of products of different sizes and shapes, thereby improving the flexibility and utilization rate of the equipment Stick Packaging Line. The following are some common technical means and design ideas to achieve this goal:

Adjustable components

Guide rail and guide rod adjustment: Adjust the width and height of the product conveying guide rail manually or electrically to accommodate products of different sizes Stick Packaging Line.

Sealing and cutting mechanism adjustment: This includes the position and pressure adjustment of the longitudinal and transverse sealing devices to ensure good sealing effects for packaging materials of different thicknesses.

Mold replacement or adjustment: The mold is a key component that determines the shape of the packaging bag. For different packaging specifications, it may be necessary to replace molds of different sizes or use adjustable molds Stick Packaging Machine.

2. Automated control system

PLC programming control: Modern bagging machines are usually equipped with PLCS (Programmable Logic Controllers), which can quickly switch production parameters such as speed and temperature by pre-setting different programs.

Touchscreen operation interface: Users can select preset product specification parameters on the touchscreen and switch to the desired production mode with one click Stick Packaging Line.

Servo motor drive: The use of servo motors can more precisely control the position and speed of each moving part, facilitating the rapid and accurate completion of specification conversion.

3. Modular design

Modular structure: Some high-end models adopt a modular design concept, allowing users to add or remove certain functional modules, such as coding units and detection units, according to actual needs. It also facilitates the adjustment work when switching specifications.

Quick change system: In response to the frequent change of specifications, a dedicated quick change system has been designed. For instance, key components such as molds and fixtures can be replaced within a few minutes.

4. Data Management and Storage

Formula management system: Save the best packaging parameters of multiple products as "formulas". When it is necessary to change the packaging specifications, simply load the corresponding formula and the relevant Settings will be automatically adjusted.

Remote monitoring and diagnosis: Some advanced equipment supports remote access. Technicians can debug and maintain the equipment through the network, helping customers solve problems more quickly and optimize production processes.

In conclusion, the multi-specification switching ability of the strip bag assembly depends on the flexibility of its hardware design and the intelligence level of its software system. When making a purchase, one should choose the appropriate configuration based on their own production needs and take into account the technical support and service level provided by the supplier.