The small package liquid sauce packaging machine is an automated packaging equipment specially designed for small-volume liquid or semi-liquid materials sauce packet machine, suitable for the small packaging requirements of condiments such as soy sauce, vinegar, tomato sauce, and chili sauce. This type of machine is particularly suitable for enterprises that need to precisely control the amount of contents in each package, especially in the food processing industry sauce packing machine.

Main features

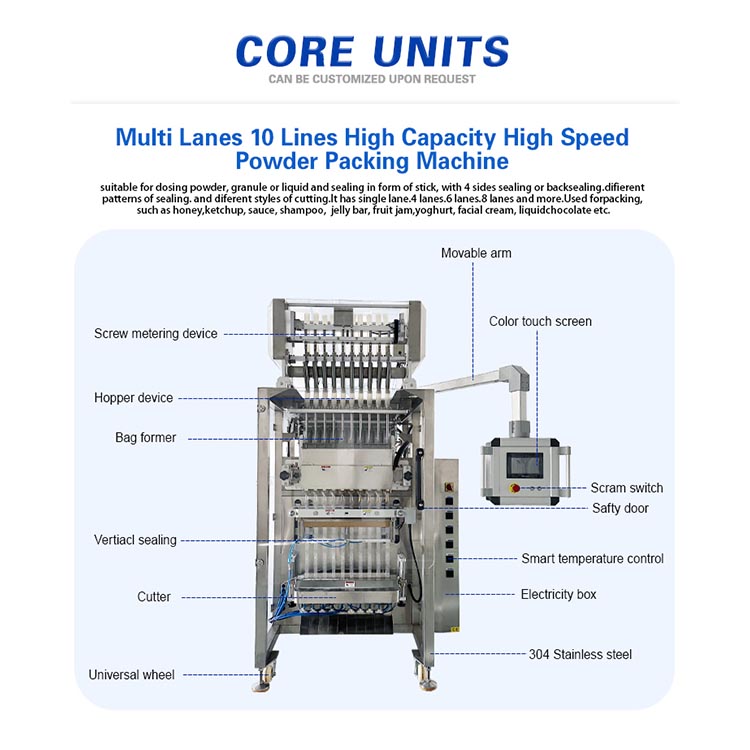

Precise measurement: High-precision pumping systems or volumetric metering devices are adopted to ensure that the amount filled each time is extremely accurate, meeting the requirements of small packaging specifications sauce packing machine.

Strong adaptability: It can handle liquids and semi-fluid materials of different viscosities ketchup packaging machine, effectively packaging from low-viscosity liquids to relatively thick sauces sauce packing machine.

Multiple packaging forms: Supports pillow bags, spout bags, stand-up bags and other forms ketchup packaging machine. The most suitable packaging style can be selected according to the product characteristics and market demand.

Small packaging specifications: Particularly suitable for single-portion or small-capacity packaging, such as common 5g, 10g and other small packaging specifications sauce packing machine.

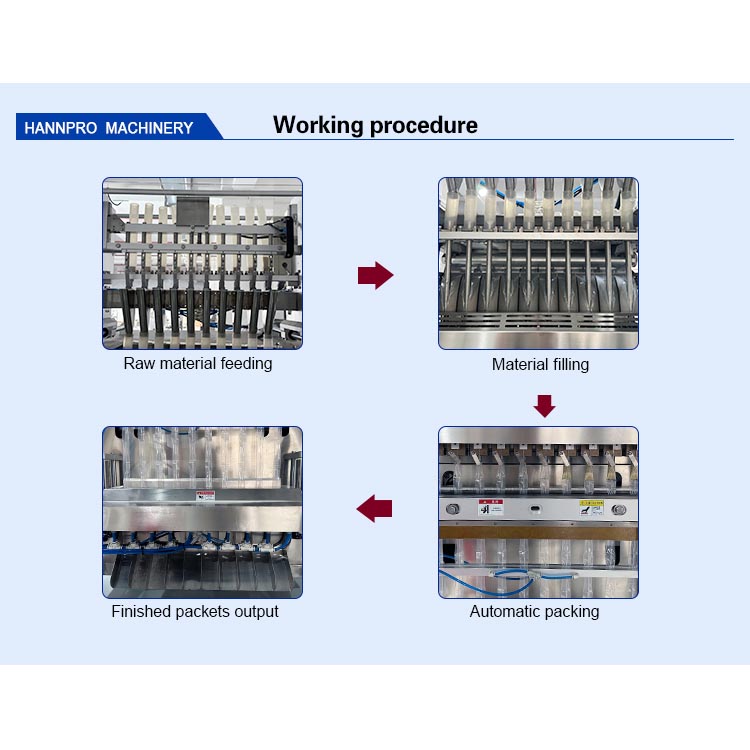

High-efficiency production: Even in small packages, through optimized design and multi-column parallel working mode ketchup packing machine, high production efficiency can still be guaranteed sauce packing machine.

Easy to clean and maintain: Considering hygiene standards, especially for food packaging, the design is convenient for quick disassembly and cleaning, especially the parts that come into direct contact with the materials, ensuring food safety sauce packing machine.

Intelligent control system: Equipped with a touch screen human-machine interface, it is easy and intuitive to operate, offers flexible parameter Settings, and has a self-diagnosis function for faults, which helps to reduce downtime and improve production efficiency.

Select key points

Material characteristics: Select the appropriate machine type based on the physical properties of the liquid or sauce to be packaged, such as viscosity and fluidity sauce packing machine.

Packaging capacity: Determine the minimum required packaging capacity and select a packaging machine that can meet this requirement while maintaining high-precision measurement sauce sachet packing machine.

Production efficiency: Consider the production scale and select the packaging machine model that meets the production capacity requirements sauce packing machine.

Packaging materials: Confirm whether the selected machine is compatible with the packaging materials planned for use, such as different plastic film materials, etc.

Cost-effectiveness: Make an economically reasonable choice by comprehensively considering the equipment investment cost, operating cost and expected production benefits sauce packing machine.

When choosing a small package liquid sauce packaging machine, it is very important to understand the specific requirements of your own products and market trends, as this will directly affect whether the final selected equipment can meet various requirements in actual production.