The powder multi-column packaging machine is a high-capacity automated packaging equipment in the modern packaging industry powder packing machine. The following will provide a detailed introduction from the dimensions of its working principle, features, and applications:

Working principle

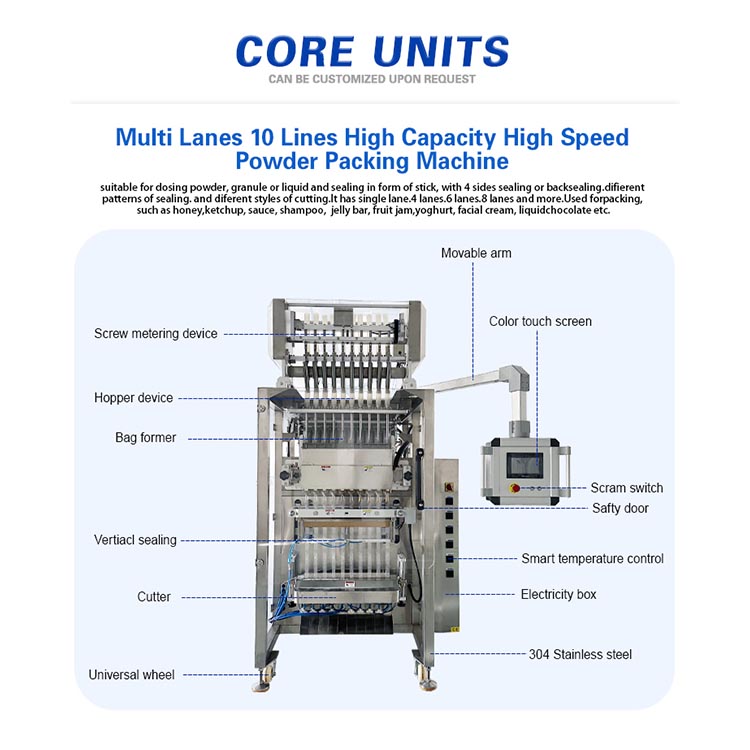

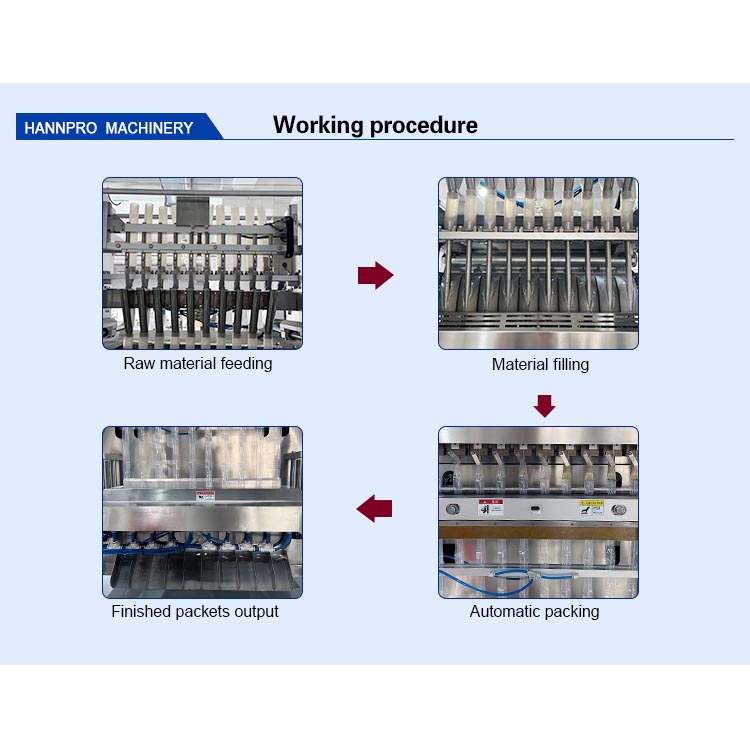

Automatic feeding: Through the feeding system, powder materials are evenly and precisely distributed to each packaging channel powder filling and sealing machine. Then, the powder is precisely measured by the metering device to ensure that the amount of powder in each packaging bag meets the set standard powder packing machine.

Bag forming: After the packaging materials go through processes such as unwinding and pulling, under the action of the forming machine, they are folded and curled according to the set bag shape requirements to form multiple parallel cylindrical packaging bag prototypes powder packing machine.

Sealing and marking: The packaging bags are sealed through sealing devices, usually by methods such as heat sealing, to ensure good sealing performance of the packaging bags powder bagging machine. Meanwhile, the date, batch number, product information and other contents are marked on the packaging bag through the identification device powder packing machine.

Discharge and stacking: The finished packaging bags are discharged through the discharge port and can then be neatly stacked through the stacking mechanism, facilitating subsequent handling, storage and transportation powder packing machine.

Characteristics

High-efficiency production: It can simultaneously perform operations such as filling and sealing multiple packaging bags, significantly enhancing packaging efficiency and meeting the demands of high-volume production automatic powder filling machine. For instance, a packaging machine with 4 to 12 channels can package 120 to 360 bags or even more per minute powder packing machine.

Precise measurement: Equipped with high-precision measurement devices and advanced control systems, such as cylindrical blade screw servo motor-driven feeding devices, each row of bags can be independently set and fine-tuned for measurement on the human-machine interface, ensuring accurate measurement of powder materials and reducing errors powder packing machine.

High degree of automation: The entire packaging process, from automatic feeding, bag making, filling, sealing, marking to discharging and stacking, can all be operated automatically, reducing manual intervention, lowering labor intensity, and enhancing the stability and consistency of production powder packing machine.

Strong adaptability to bag types and packaging materials: According to different product requirements, various bag types can be achieved by changing molds or adjusting parameters, such as three-side sealed, four-side sealed, and back-sealed bag types. Meanwhile, it can adapt to various packaging materials, such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE, etc powder packing machine.

Fault detection and alarm function: Equipped with a complete fault detection system, it can automatically detect various faults during the operation of the equipment, such as material blockage, exhausted packaging materials, poor sealing, etc., and promptly issue alarm signals, display the cause of the fault, facilitating operators to quickly identify and solve problems, and ensuring the normal operation of the equipment powder packing machine.

Application field

Food industry: Widely used in the packaging of powdered foods such as milk powder, meal replacement powder, seasonings, enzyme powder, coffee powder, protein powder, solid beverages, probiotics, milk tea powder, soy milk powder, and fruit and vegetable powder powder packing machine.

Pharmaceutical industry: Suitable for packaging of pharmaceutical powders such as glucose, Sanqi powder, medicinal powder, cold granules, probiotics, donkey-hide gelatin powder, Ganoderma lucidum mycelium powder, and Zuguang powder spice pouch packing machine.

Daily chemical industry: It can be used for packaging daily chemical products such as laundry powder, disinfectant powder, and cosmetic powder.

Technological development trend

Intelligence: With the development of artificial intelligence technology, powder multi-column packaging machines will be equipped with stronger intelligent functions, such as automatic optimization of packaging parameters, self-diagnosis, and predictive maintenance, further enhancing the operational efficiency and reliability of the equipment powder packing machine.

Energy conservation and environmental protection: In terms of energy consumption and environmental protection, future powder multi-row packaging machines will adopt more energy-efficient drive systems and environmentally friendly materials to reduce energy waste and environmental impact powder packing machine.

Multi-functional integration: To meet the demands of enterprises for production efficiency and space utilization, the powder multi-column packaging machine will be integrated with other production equipment such as labeling machines, inkjet printers, and cartoning machines to form an integrated packaging production line, achieving a fully automated process from powder packaging to finished product warehousing powder packing machine.