Horizontal packaging machines can be equipped with different metering systems (such as volumetric type, weighing type, counting type, etc.) to meet the packaging requirements of various forms of materials (solid, granular, powder, liquid) Pillow Packing Machine.

In addition, they can also be customized according to specific application scenarios, including but not limited to adjusting packaging size, speed, and choosing appropriate packaging materials (such as plastic film, aluminum foil, etc.).

The customization options for horizontal packaging machines can be adjusted according to the specific needs of customers and product characteristics to ensure the best packaging effect and production efficiency Pillow Packaging Machine. The following are some common customization options:

Packaging size:

Adjustable feed ports, discharge ports and sealing devices are available to accommodate products of different sizes.

Customize different lengths and widths of packaging bags to meet diverse packaging needs Pillow Packing Machine.

Measurement system

Select the appropriate measurement method based on the type of material, such as volumetric, weighing, counting, etc.

For liquids or pastes, a pumping device can be equipped; For granules or powders, a vibrating disc or a screw feeder may be required Pillow Packing Machine.

Sealing form:

Choose different sealing techniques, such as hot-press sealing, ultrasonic sealing, cold sealing adhesive sealing, etc., based on the characteristics of the product and the requirements of the packaging materials Pillow Packaging Machine.

The sealing style can also be customized, such as straight edge sealing, patterned sealing, etc.

Degree of automation

Different levels of automation configurations from manual, semi-automatic to fully automatic, including functions such as automatic feeding, automatic weighing and automatic labeling.

The automated conveyor belt system is used to achieve continuous operation and production line integration Pillow Packing Machine.

Material compatibility

Support the selection of various packaging materials, such as PE film, PP film, composite film, etc.

Special material processing capabilities, such as the application of special functional membrane materials like anti-static films and moisture-proof films Pillow Packing Machine.

Additional functions:

Print batch numbers, dates or barcodes Pillow Packing Machine.

Detection systems before and after packaging, such as weight detection, metal detection, etc.

Vacuum packaging or gas displacement (MAP) function is suitable for the demand of extending the shelf life.

Safety and Hygiene Design

Designed in compliance with GMP standards, it is easy to clean and maintain Pillow Packing Machine.

Safety protection devices, such as emergency stop buttons and protective door locks, ensure the safety of operators.

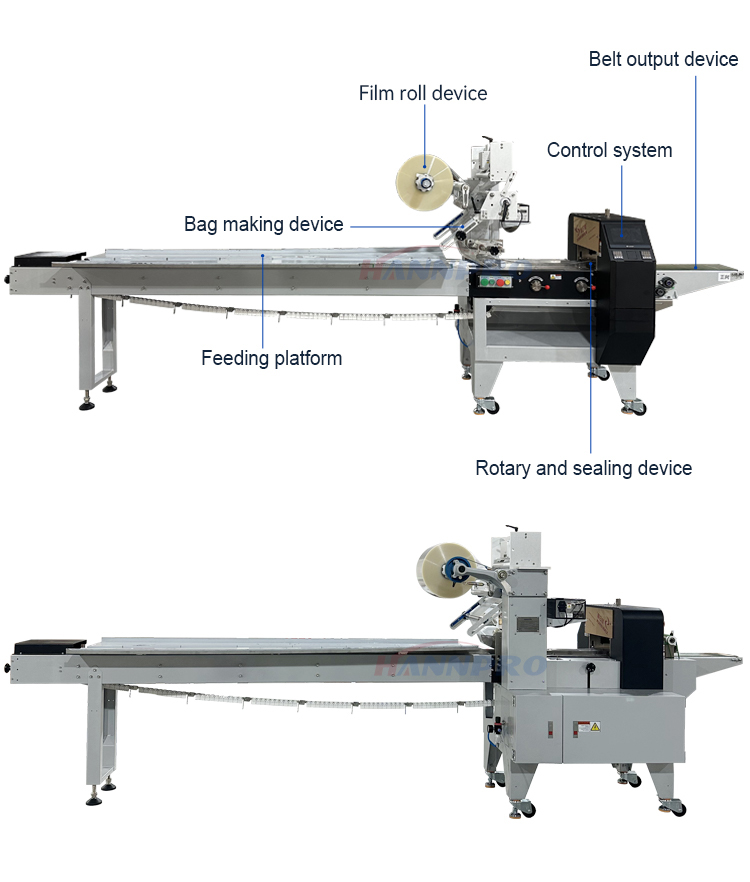

Control system

The programming of the PLC control system can be personalized according to the customer's requirements.

The touchscreen interface provides a friendly human-computer interaction experience and allows users to easily adjust parameters.

Environmental adaptability

The equipment can operate normally within a specific temperature range and humidity conditions Pillow Packing Machine.

Corrosion-resistant design, suitable for use in the chemical industry.

These customized options can help enterprises select the most suitable horizontal packaging machine configuration based on their product features and production process requirements, thereby enhancing production efficiency and ensuring product quality Pillow Packing Machine. When communicating with suppliers, it is crucial to clearly define specific requirements so as to obtain the most suitable solution for the enterprise.