The liquid strip packaging automatic machine is an automated device specifically designed for packaging liquid products into strip forms Liquid Sachet Packing Machine. The following is a detailed introduction to it:

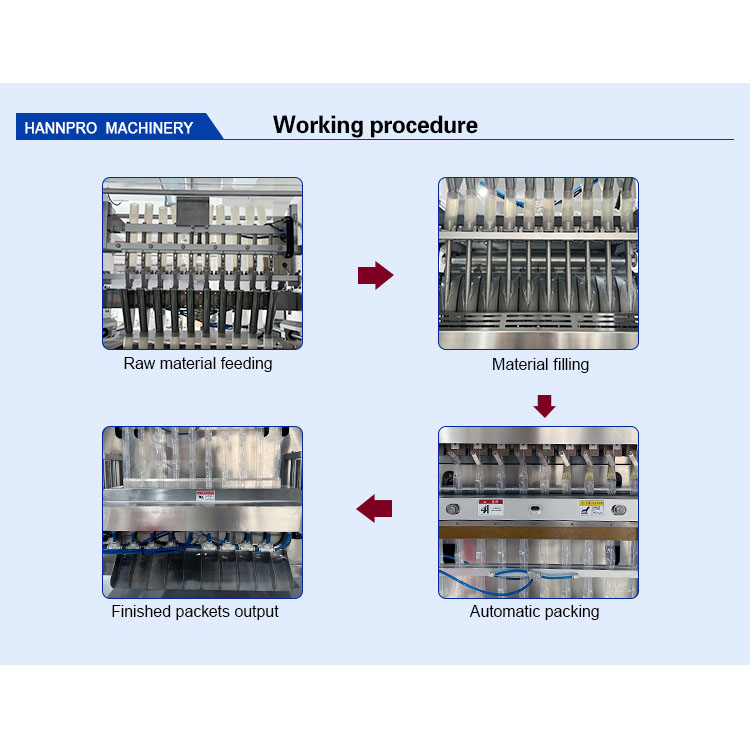

Working principle

Bag forming: The packaging material is unrolled from the roll and conveyed to the forming machine through the traction device. Under the action of the forming machine, it is wound into a cylindrical shape Liquid Sachet Packing Machine. Then, the connection points of the cylindrical packaging material are heated and pressurized through the longitudinal sealing device to achieve longitudinal sealing and form a bag cylinder Liquid Packing Machine.

Material filling: After the liquid material is precisely measured by the metering device from the feeding system, it is injected into the formed bag cylinder through the discharging device Liquid Sachet Packing Machine.

Sealing and cutting: The transverse sealing device performs transverse heat sealing on the bag tube to form a transverse seal Liquid Packing Machine. At the same time, the cutting device cuts off the transverse sealing area, separating the packaged strip from the unpackaged part, thus completing the packaging process of one strip Liquid Sachet Packing Machine.

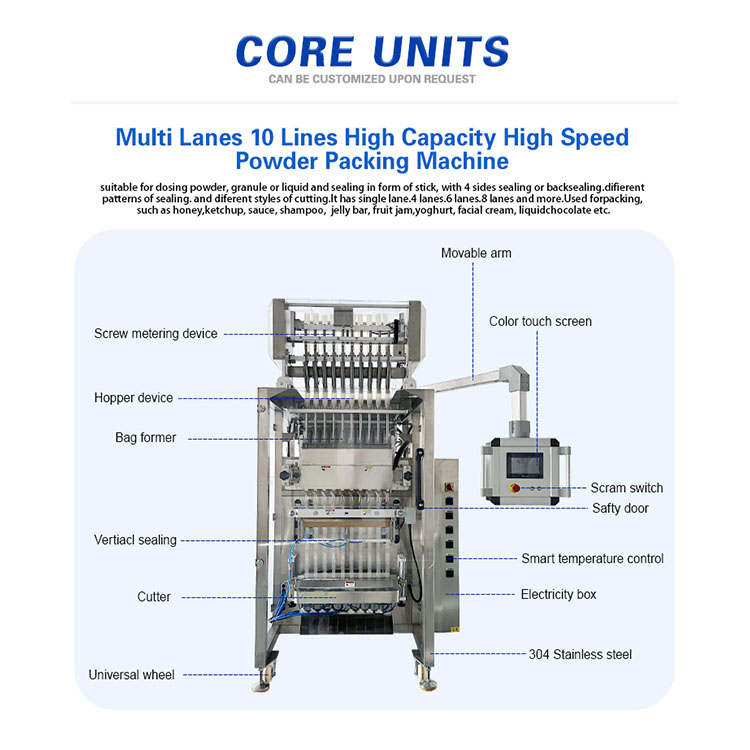

Structural composition

Packaging material supply system: It includes packaging material drum supports, traction rollers, tension control systems, etc., which are responsible for accurately and smoothly transporting packaging materials to the packaging position and controlling the tension of the packaging materials to ensure the smooth progress of the packaging process Liquid Sachet Packing Machine.

Liquid metering and filling system: Composed of metering pumps, storage tanks, conveying pipelines, filling heads, etc., it can select appropriate metering methods and filling equipment according to different liquid characteristics and packaging requirements to achieve precise metering and filling of liquid materials Liquid Stick Packing Machine.

Bag forming and sealing system: Mainly composed of a forming device, longitudinal sealer, transverse sealer and cutting device, etc., it is a key component for achieving packaging forming and sealing, determining the shape, size and sealing quality of the strip package Liquid Sachet Packing Machine.

Control system: Generally, a programmable logic controller (PLC) combined with a touch screen operation interface is adopted, which can set and adjust various parameters of the packaging machine, such as packaging speed, filling volume, sealing temperature, sealing time, etc. At the same time, it also has functions such as fault diagnosis, alarm prompt, and data recording, making it convenient for operators to monitor and manage the equipment Liquid Sachet Packing Machine.

Conveying and discharging system: It includes the feeding conveyor belt and the discharging conveyor belt. The feeding conveyor belt transports the liquid materials to be packaged to the packaging position, while the discharging conveyor belt transports the packaged strip products to subsequent processes such as coding, boxing, and warehousing Liquid Sachet Packing Machine.

When liquid packaging machines are adapted to special liquid requirements, they usually need to take into account the physical and chemical properties of the liquid, such as viscosity, corrosiveness, volatility, etc. The following are several common adjustment and improvement methods to ensure that the liquid packaging machine can effectively handle various types of liquids:

For high-viscosity liquids: For high-viscosity products such as honey, syrup or certain sauces, it may be necessary to use packaging machines with powerful pumping systems or adopt volumetric filling technology to ensure precise measurement. In addition, the design of the conveying pipelines and valves also requires special attention to reduce resistance and prevent blockage.

Selection of corrosion-resistant materials: If the liquid is corrosive (such as certain chemicals or acidic beverages), the parts of the machine that come into contact with the liquid should be made of corrosion-resistant materials, such as stainless steel, Teflon coating, etc., to extend the service life of the equipment and ensure food safety Liquid Stick Packing Machine.

Anti-volatilization measures: For volatile liquids such as alcoholic beverages or certain solvents, the packaging process should be carried out in a closed environment, and the time from filling to sealing should be shortened as much as possible to reduce volatilization losses. Sometimes, the method of replacing air with inert gas is also used to reduce the oxygen content inside the packaging and protect the product quality.

Temperature control: Some liquids become extremely viscous or even solidify at low temperatures, and may become thinner or undergo other changes at high temperatures. Therefore, according to the characteristics of the liquid, it is very important to heat or cool the material storage tank and filling head to maintain an appropriate working temperature.

Cleanliness and hygiene requirements: For the food and pharmaceutical industries, cleanliness is of vital importance. The design should be convenient for cleaning and disinfection to avoid cross-contamination. The CIP (On-site Cleaning) system can automate this process, enhancing efficiency while ensuring hygiene standards.

Customized solutions: For extremely special liquids, manufacturers may offer customized services, including but not limited to changing filling methods, adjusting packaging speeds, and optimizing packaging material selection, to meet specific application scenarios Liquid Sachet Packing Machine.

Through the above-mentioned targeted designs and adjustments, the liquid packaging machine can well adapt to the demands of different types of special liquids, thereby ensuring the quality of the products and the smooth progress of production.