he liquid beverage strip packaging machine is a device used to automatically package liquid beverages into strip forms. The following will introduce it from dimensions such as its working principle, structural composition, features, and application scenarios:

Working principle

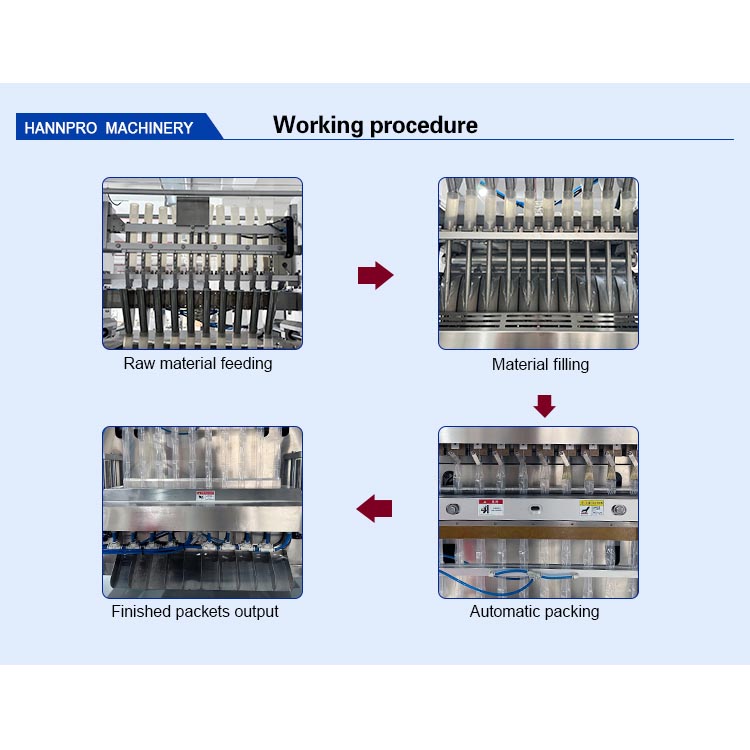

Bag forming: The packaging materials on the roll, such as polypropylene film Jelly Stick Packing Machine, are guided by the traction roller and gradually wound into a button-shaped roll by the lap-type bag forming machine. The longitudinal sealing roller on the longitudinal sealer is heated and pressurized at the button-shaped area to seal it longitudinally firmly, forming the bag roll.

Material filling: After the liquid beverage is measured in the self-feeding box Jelly Packing Machine, the filling cylinder composed of the feeding trough and the inner wall of the mold is led into the formed plastic bag Jelly Stick Packaging Machine.

Sealing and cutting: The transverse sealer performs transverse heat sealing on the bag tube to form a transverse seal. Then, the cutting device cuts and separates the transverse seal along the center line, completing the top seal of the packaging bag and the bottom seal of the next bag, thus forming an independent strip package.

Intelligent control system: Equipped with PLC (Programmable Logic Controller) + touch screen interface, it is easy to operate, adjust parameters and monitor the operating status Jelly Stick Packing Machine.

Date printing/label attaching: Labels capable of printing the production date, expiration date or attaching other relevant information on each package.

Fault detection and alarm system: When abnormal conditions occur in the equipment, it will automatically shut down and issue an alarm to ensure the continuity and safety of production Jelly Stick Packaging Machine.

Example of technical parameters

Packaging speed: Usually between 30 and 100 packs per minute, depending on the model and product type.

Packaging size range: The length and width can be adjusted according to requirements to adapt to strip packages of different sizes Jelly Stick Packing Machine.

Power supply requirements: The common ones are 220V 50Hz or 380V 50Hz, and the power is generally between 2 and 5 kilowatts Jelly Stick Packaging Machine.

Air source pressure: If pneumatic components are included, an air source pressure of approximately 0.6MPa must be provided.

The overall weight of the machine varies depending on the model, approximately ranging from 500kg to 1000kg Jelly Stick Packaging Machine.

Customizing the parameters of packaging machines based on requirements is a process involving multiple aspects, aiming to ensure that the equipment can efficiently and accurately meet the packaging requirements of specific products Jelly Stick Packing Machine. The following are the main steps and key points to consider when customizing the parameters of the packaging machine:

1. Determine the product specifications

Product type: Clearly specify the type of product to be packaged (such as liquid, powder, granule, etc.).

Size and weight: Determine the size and weight of each packaging unit, including length, width, height and filling amount Jelly Stick Packing Machine.

Material properties: Understand the nature of packaging materials, such as whether they are fragile, viscous or corrosive, etc Jelly Packing Machine.

2. Equipment performance matching

Packaging speed: Set an appropriate packaging rate based on the production plan to balance efficiency and quality Jelly Stick Packing Machine.

Precision requirements: For metering filling type packaging machines, it is necessary to be accurate to the gram or milliliter level to ensure consistency Jelly Packing Machine.

Adaptive adjustment: Select machines that are easy to adjust to facilitate rapid conversion and production of products of different specifications.

3. Special functional requirements

Sealing method: Select heat sealing, cold sealing or other sealing techniques based on the product characteristics Jelly Stick Packing Machine.

Printing/labeling function: If it is necessary to mark the date, batch number and other information on the packaging, a corresponding printing device should be configured Jelly Packing Machine.

Additional options: Consider whether special functions such as inflatable preservation, anti-counterfeiting labels, and easy-tear opening designs are needed.

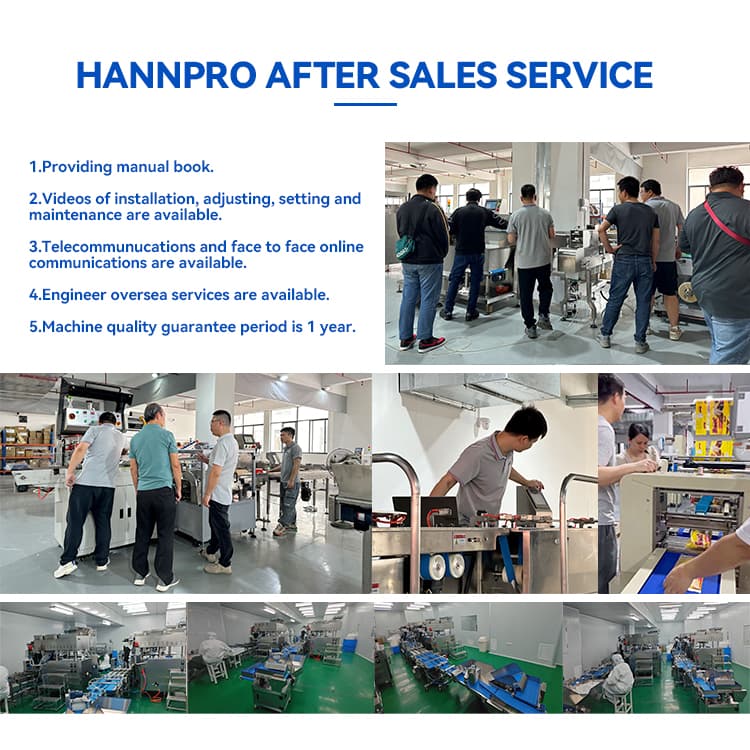

4. Technical support and services

Supplier capabilities: Seek out manufacturers with rich experience and technical strength to ensure they can provide comprehensive technical support and services Jelly Stick Packing Machine.

Training and guidance: Confirm whether the supplier provides operator training and long-term maintenance suggestions.

Trial operation and commissioning: Conduct thorough tests before official use to ensure that all Settings meet expectations and make timely adjustments and optimizations.

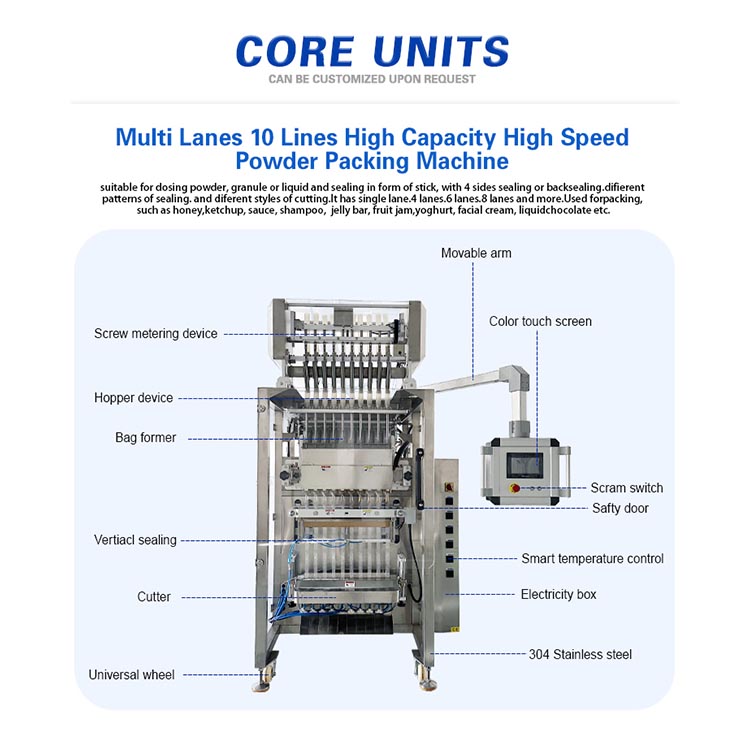

Bag forming and sealing system: It mainly includes a flip bag forming device, a longitudinal sealer, a transverse sealer and a cutting device, etc., which complete the forming, longitudinal and transverse sealing and cutting actions of the packaging bag Jelly Stick Packing Machine.

Control system: It usually adopts a programmable logic controller (PLC) combined with a touch screen interface to achieve overall control of the packaging machine. Parameters such as packaging speed, filling volume, sealing temperature, and cutting position can be set. It also has functions such as fault alarm, operation record, and parameter memory Jelly Stick Packaging Machine.

Conveying and discharging system: It includes the feeding conveyor belt and the discharging conveyor belt, which transport the liquid beverages to be packaged to the packaging position and the packaged strip products to the next process, such as coding and boxing Jelly Packing Machine.