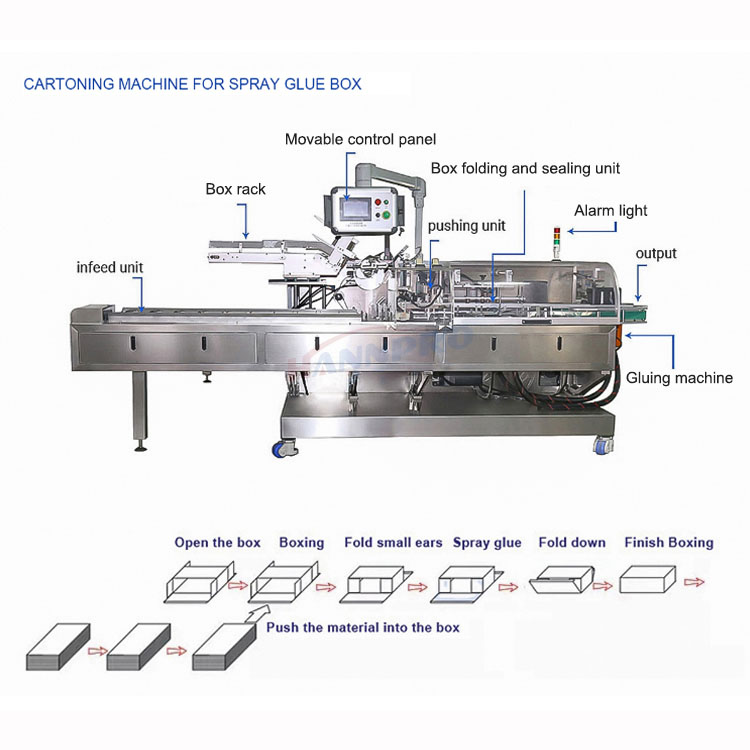

The horizontal automatic cartoning machine is an automated device specially designed to efficiently and accurately load products into paper boxes case packing equipment. It is usually applicable to various industries bottle case packer machine, such as pharmaceuticals, food, cosmetics, electronic products, etc. It is a very important production equipment for enterprises that need a large amount of packaging.

Main features

Automatic shutdown when the product is not properly placed in the box: When it is detected that the product has not been correctly placed in the paper box, the machine will automatically stop running to prevent damage or incorrect packaging case packing equipment.

No paper box, continuous without manual, no product automatic shutdown: If the system detects the absence of necessary components (such as paper boxes, manuals or products), it will also automatically stop the operation drop case packer.

It is convenient to change the specifications of different products: Easy to adjust to adapt to different product sizes and shapes, which improves the flexibility of production case packing equipment.

The main drive is equipped with an overload protection device: ensuring the safety of the equipment in case of overload and preventing mechanical damage case packing equipment.

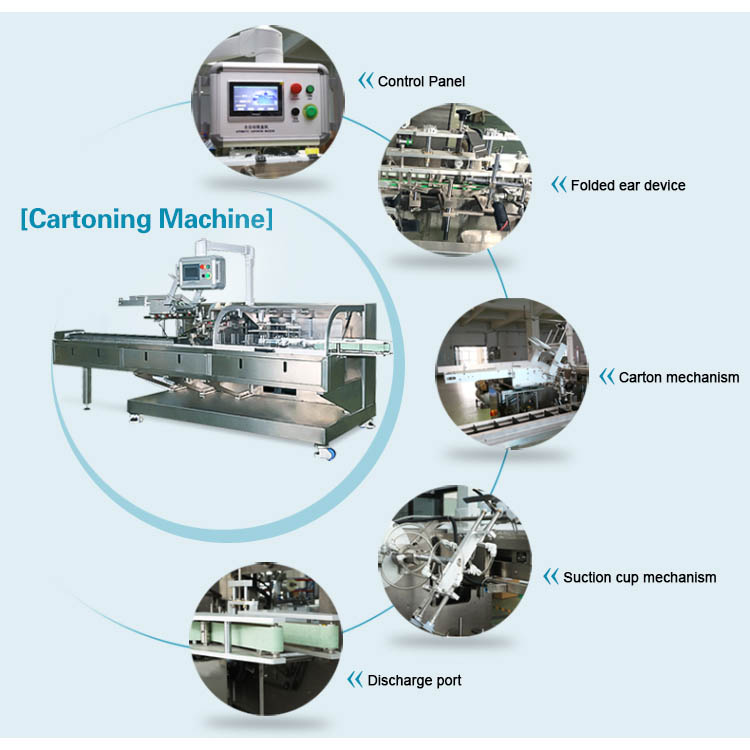

PLC automatically displays the boxing speed and finished product count: Precise control of the production process is achieved through a programmable logic controller (PLC), and real-time monitoring is provided.

Self-diagnosis function for faults: It can automatically identify and display fault information, facilitating quick maintenance packer machine.

Automatic rejection function: It can identify substandard products or packaging and remove them from the production line case packing equipment.

Example of technical parameters

Production capacity: The main unit operates at a speed of 50 to 90 boxes per minute.

Gas consumption: 20 cubic meters per hour (pressure 0.5-0.7MPa) case packing equipment.

Paper box quality: It is recommended to use cardboard with a weight of 250-350 grams per square meter.

Specification range: Maximum size (LxWxH) 200x90x60mm, minimum size (LxWxH) 70x20x15mm.

Power supply: AC 380V three-phase four-wire, 50Hz case packing equipment.

Total power: approximately 1.5KW.

Weight: Approximately 1.2 tons side load case packer.

Application scenarios

Horizontal automatic cartoning machines are particularly suitable for occasions that require high-speed and high-precision packaging operations, such as blister packaging in the pharmaceutical industry, packaging of bottled medicines, as well as packaging of daily necessities and electronic products case packing equipment. This type of equipment is usually produced by professional manufacturers and can be customized with different configurations and functions according to customer needs. If you are looking for such equipment, you can contact the relevant manufacturer to obtain the latest quotations and technical support.

The automation level of the horizontal automatic cartoning machine can be enhanced through the following several ways:

Integrate more advanced sensor technologies:

The use of high-precision sensors, such as photoelectric sensors and laser rangefinders, can enhance the accuracy and response speed of detection. For example, it is used to detect whether the product has entered the paper box correctly or whether there are any missing components.

Adopt an intelligent control system:

Upgrade to an advanced control system based on PLC (Programmable Logic Controller) or PC (Personal Computer), and integrate the concept of Industry 4.0 to enable the equipment to exchange data and be remotely monitored via the network.

By leveraging Internet of Things (IoT) technology, real-time data on the operational status of devices is collected to facilitate maintenance predictions and performance optimization case packing equipment.

Introduce artificial intelligence and machine learning:

Apply AI technology to analyze the production process to identify patterns and optimize operation parameters, reducing downtime and scrap rates.

Through the machine vision system, various parameters during the boxing process are automatically adjusted, such as automatically regulating the feeding speed and direction according to the shape and size of the product.

Add automated auxiliary equipment:

By combining the use of peripheral equipment such as automatic feeding systems, automatic carton sealing machines and palletizing robots, a complete automated production line is formed.

Realize the full automation of material handling, covering all links from raw material supply to finished product outbound case packing equipment.

Enhanced Human-Machine Interface (HMI)