The honey strip multi-column packaging machine is an automated packaging equipment specifically designed for honey products, especially suitable for encapsulating honey into individual strip packaging Honey Packing Machine. This type of packaging machine is highly suitable for businesses that wish to sell honey in small portions, such as single-use honey strips. It is convenient to carry and easy to control the amount used. The following is some basic information about the multi-column packaging machine for honey strips:

Main functional characteristics

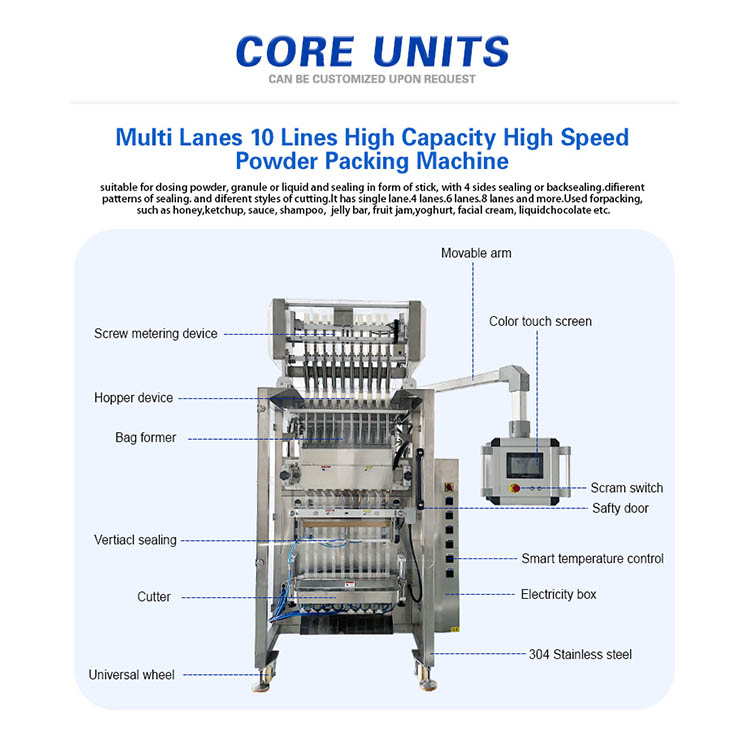

Multi-column packaging: It can handle multiple packaging columns simultaneously, improving production efficiency Honey Packing Machine.

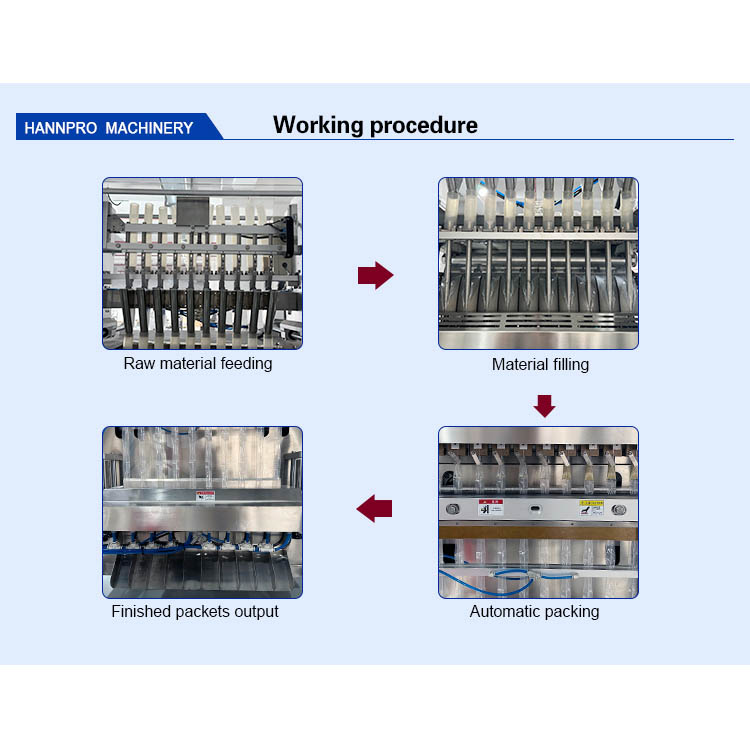

Automatic metering and filling: According to preset parameters Honey Sachets Packing Machine, it can accurately measure and fill honey into each packaging bag.

The packaging materials have wide adaptability: It supports various packaging materials, such as composite film, aluminum foil, etc., to ensure the freshness and shelf life of honey.

High-efficiency sealing technology: Heat sealing or cold sealing technology is adopted to ensure the sealing of the packaging and prevent leakage Honey Packing Machine.

Intelligent control system: Equipped with PLC (Programmable Logic Controller) and touch screen operation interface, it is convenient to adjust Settings and monitor the operating status Honey Sachets Packing Machine.

Date printing function: It can print information such as production date and expiration date on the packaging Honey Stick Packing Machine.

Fault detection and alarm system: When the machine malfunctions Honey Stick Packing Machine, it will automatically shut down and issue an alarm Honey Packing Machine.

Example of technical parameters

Packaging speed: It depends on the specific model and is usually between 30 and 100 packs per minute Honey Packing Machine.

Packaging size range: The length and width can be adjusted as needed to adapt to the packaging of honey strips of different sizes.

Power supply requirements: The common ones are 220V 50Hz or 380V 50Hz Honey Sachets Packing Machine.

Power: Generally between 2 and 5 kilowatts, depending on the specific model Honey Packing Machine.

Air source pressure: If the equipment contains pneumatic components Honey Packaging Machine, the corresponding air source pressure needs to be provided, which is usually around 0.6MPa Honey Sachets Packing Machine.

Application scenarios

Individual small packages of honey products, suitable for the retail market Honey Packing Machine.

Packaging of other similar viscous liquids or pastes, such as sauces Honey Packaging Machine, syrups, etc Honey Sachets Packing Machine.

Purchasing suggestions

Determine the packaging specifications: Understand the specific size and weight of the honey strips you need to package in order to select the appropriate machine.

Production capacity matching: Consider the scale of your production line and the expected output to select a packaging machine with an appropriate speed Honey Packing Machine.

Budget considerations: Select products with high cost performance based on the budget, while also taking into account the long-term maintenance costs Honey Sachets Packing Machine.

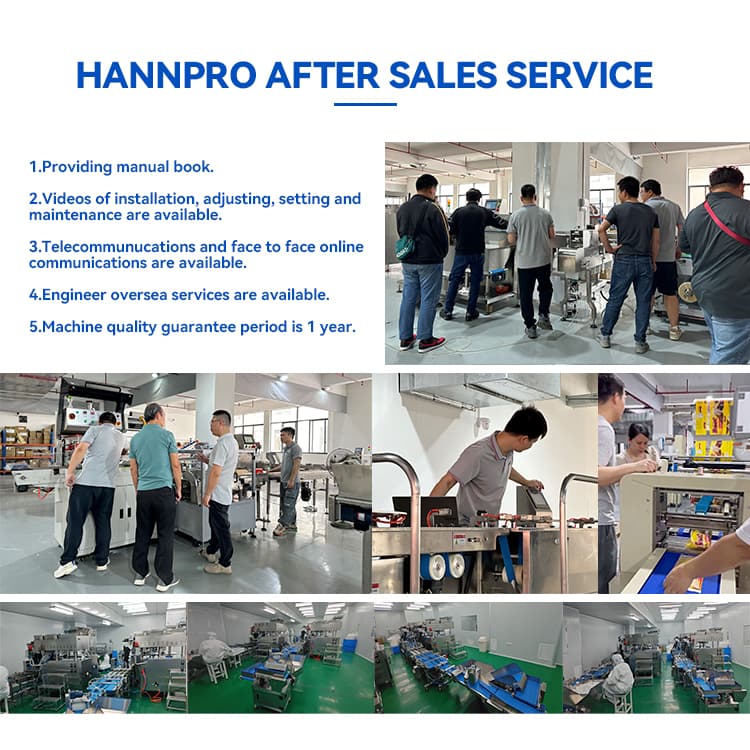

After-sales service: Choose a brand that offers good after-sales support, including installation and commissioning, training, maintenance services, etc.

When honey packaging machines adapt to special specification requirements, they usually need to achieve this by adjusting equipment parameters, replacing or customizing components Honey Packing Machine. The following are some common methods and strategies:

1. Adjust the packaging size

Change bag length and width: Most modern honey packaging machines allow users to easily set bag length and width through a touchscreen interface. For more significant adjustments, it might be necessary to manually adjust the mechanical parts Honey Sachets Packing Machine.

Use adjustable molds: Some machines are equipped with adjustable molds, allowing for quick changes in packaging sizes to fit products of different specifications Honey Packing Machine.

2. Customize the metering system

Precise control of filling volume: To meet the requirements of different specifications, the amount of honey in each package can be ensured to be accurate by adjusting the Settings of the metering pump or electronic scale Honey Sachets Packing Machine.

Multi-head weighing system: For situations where highly precise packaging is required, a multi-head computerized combined scale can be adopted, which can offer higher accuracy and speed Honey Packing Machine.

3. Special packaging material treatment

Compatible with multiple materials: Select appropriate packaging materials (such as composite film, aluminum foil, etc.) based on the storage requirements of the product, and ensure that the packaging machine can handle these materials correctly Honey Packing Machine.

Adjust the sealing temperature and time: Different packaging materials have different requirements for heat sealing. The sealing temperature and time need to be adjusted accordingly to ensure a good sealing effect Honey Sachets Packing Machine.

4. Add additional functions

Coding/label printing: To meet specific identification requirements, automatic coding or labeling functions can be added during the packaging process to mark information such as production date, shelf life, and batch number Honey Sachets Packing Machine.

Nitrogen-filled preservation technology: To extend the shelf life of honey, some high-end models also support nitrogen-filled packaging options, reducing oxygen exposure and maintaining the freshness of the product Honey Packing Machine.

5. Upgrade of automation level

Intelligent control system: Utilizing PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) to achieve automated operation, simplify the specification conversion process, and enhance production efficiency Honey Packing Machine.

Integrated production line solution: Integrate honey packaging machines with other processing equipment (such as filling machines, labeling machines) into a complete production line to meet complex production process requirements.