The High Capacity Sugar Stick Packaging Machine is a set of white sugar granule packaging machines with high circulation capacity and high speed sugar packaging machine. It can support simultaneous automatic weighing of multiple columns and automatic sealing packaging on both sides sugar stick machine.

The automatic packaging machine for white sugar granules is a device used for automatic metering, filling, sealing and other packaging operations of white sugar granules sugar stick packing machine. The following will introduce it from the dimensions of working principle, types, features and applications:

Working principle

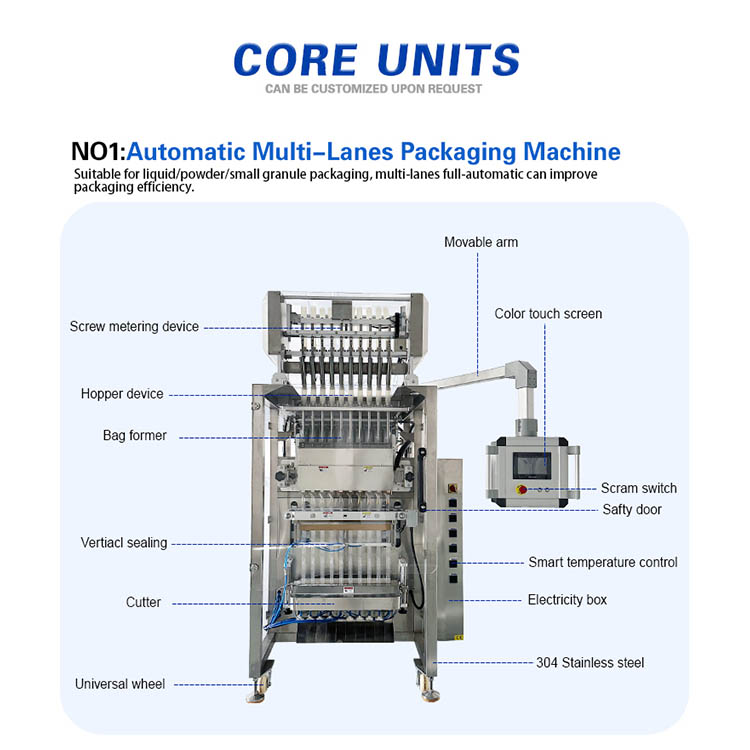

Measurement principle: Through high-precision electronic combination scales, measuring cups, screw scales or multi-head combination scales and other measurement devices, the white sugar granules are precisely measured to ensure that the weight of white sugar in each packaging bag meets the set standard sugar filling machine. For instance, high-precision electronic combination scales use sensors to measure the weight of materials and transmit the signals to the control system to achieve precise weighing sugar stick machine.

Bag-making principle: Vertical machine forming or pull-out bag-making is adopted. The roll film is formed into a cylindrical shape through a forming machine, and then the film is sealed by longitudinal and transverse sealing devices to make packaging bags. For instance, the PLC-controlled servo motor double pulling film structure can accurately control the sealing and cutting position, and the photoelectric eye can automatically follow and mark the length of the bag-making sugar stick machine.

Filling principle: The measured white sugar particles are filled into the prepared packaging bags through feeding devices such as vibrating feeders and screw feeders sugar packet packing machine.

Sealing principle: By using heat sealing technology, the sealing part of the packaging bag is heated and pressurized through heating elements, causing the film material to melt and bond together, thus achieving sealing. The horizontal and vertical seals are independently temperature-controlled to ensure a firm, beautiful and smooth seal sugar stick machine.

Main type

Vertical granule packaging machine: Compact structure, small floor space, suitable for packaging various specifications of white sugar granules. It can automatically complete a series of actions such as bag making, metering, filling, sealing and cutting. The packaging speed is relatively fast, usually 30 to 60 bags can be packaged per minute sugar stick machine.

Bag-in-bag packaging machine: It uses pre-prepared bags for packaging, and the quality and specifications of the bags are relatively stable. It can automatically take bags, open bags, measure and fill, seal, etc. It is suitable for packaging large-dose and high-quality white sugar. The packaging speed is relatively slow, but the packaging accuracy is high.

Strip packaging multi-column packaging machine: It can simultaneously measure, fill and package multiple packaging strips, improving packaging efficiency. It is often used for small-dose, multi-column packaged white sugar products, such as sugar packets and coffee creamer, with a packaging speed of generally 35 to 50 cuts per minute sugar stick machine.