The following are the core indicators for judging the performance of pillow packaging machine and the verification method based on a comprehensive evaluation of actual production requirements and technical parameters Flow Wrapper Packing Machine:

I. Core Performance Indicators

Youdaoplaceholder0 Accuracy of operation

Youdaoplaceholder0 Sealing and cutting accuracy : Servo system positioning deviation ≤±0.5mm (when running at high speed ≥200 packets per minute), photoelectric color mark tracking system requires synchronous compensation error 1011.

Youdaoplaceholder0 Temperature control accuracy : PID algorithm controls the heat sealing temperature Flow Wrapper, fluctuation range ≤±2℃, suitable for materials such as PE/OPP/ aluminum-plastic film 10 Flow Wrapper Packing Machine.

Youdaoplaceholder0 Efficiency and stability

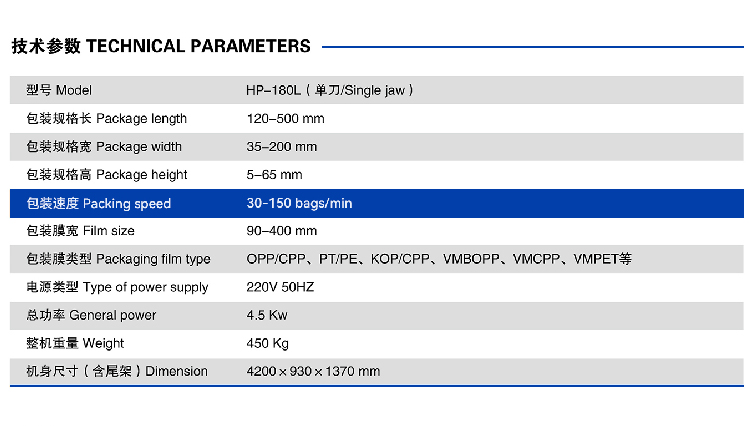

Youdaoplaceholder0 Packaging speed : Standard model 50-300 packs per minute, actual production capacity needs to match the manual feeding speed (e.g. Double servo model up to 400 packs per minute) 911.

Youdaoplaceholder0 Continuous operation : MTBF (Mean Time Between Failures) ≥2000 hours Flow Wrapper, drive noise ≤65dB, bearing temperature rise ≤70 ° C Flow Wrapper Packing Machine 4

Ii. Key Technology Configuration

Youdaoplaceholder0 Drive system

Youdaoplaceholder0 Three servo motors (independent control of film feeding/middle sealing/cross-cutting) : Ensure three-axis synchronization, more precise adjustment, noise reduction by 40%12.

Youdaoplaceholder0 Double frequency converter : Support bag length "set and cut", change time ≤3 minutes 10 Flow Wrapper Packing Machine.

Youdaoplaceholder0 Smart control

10-inch touch screen: Integrated with over 20 parameter adjustments, self-diagnosis of faults (0.5-second alarm), and positioning shutdown function 510.

Youdaoplaceholder0 MES communication interface : To meet the traceability requirements of production data in the pharmaceutical/food industry 6.

Iii. Compatibility Verification

Youdaoplaceholder0 Product compatibility

If the number of single-machine compatible product types is no more than 5 and the size difference is greater than 20%, 16 sub-machine configurations are required.

Youdaoplaceholder0 Special scenario verification :

Fragile items: Buffer inflation module test (breakage rate <0.3%) 1 Flow Wrapper Packing Machine.

Sticky products: Teflon hopper anti-sticking test 1

Iv. Long-term Operation and Maintenance Costs

Youdaoplaceholder0 Energy consumption and loss

Servo models are 15 to 20% more energy-efficient than traditional motors and increase the utilization rate of membrane materials by 12%.

Warranty terms for vulnerable parts: Clearly define the replacement cycle for cross-sealing knives, photoelectric sensors, etc Flow Wrapper. 3 Flow Wrapper Packing Machine.

Youdaoplaceholder0 After-sales service response

24-hour on-site service is required, and the warranty covers 68 core transmission components Flow Wrapper Packing Machine.

Key points : Performance verification must be carried out through material test , simulating the actual production environment to check the stability of sealing and cutting and the pass rate of finished products 57.