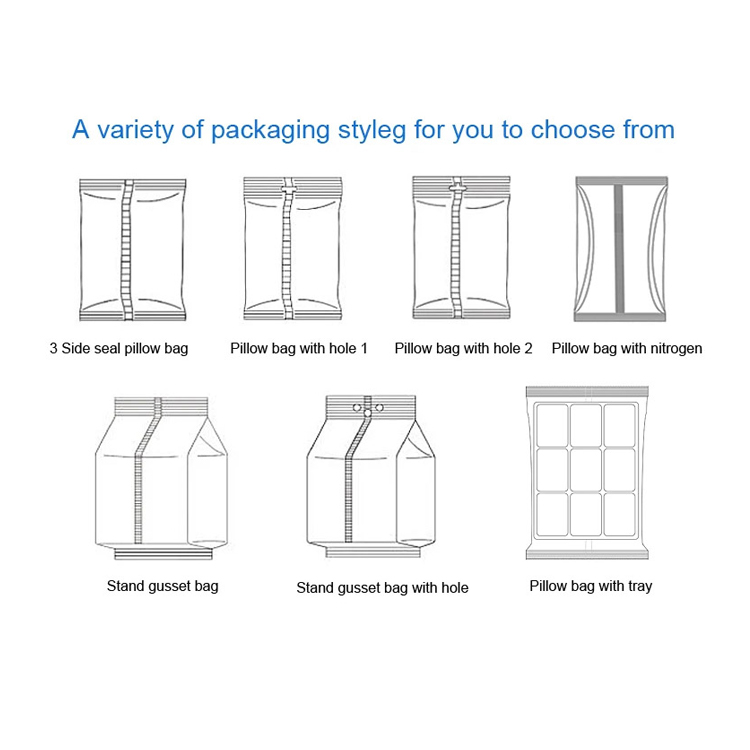

The main functions of the pillow packaging machine include but are not limited to automatic feeding, metering, filling, sealing and cutting steps Flow Wrapper Machine.

It can efficiently complete the packaging process of products through a series of precisely designed mechanical components and control systems. For instance Flow Wrapper Packaging Machine, it can unroll the cylindrical packaging material and form it into a cylinder through a mold, then add the product into this cylinder, followed by longitudinal and transverse heat sealing, and finally cut it into individual packaging bags Flow Wrapper Machine.

The after-sales service guarantee system of pillow packaging machine needs to be comprehensively evaluated from four dimensions: response time, technical ability, spare parts supply, long-term maintenance Flow Wrapper Machine, the following are the key evaluation criteria and industry practice:

I. Core Service Terms

Youdaoplaceholder0 Response timeliness and coverage

Youdaoplaceholder0 Emergency Response : We will arrive at your place within 24 hours after reporting the fault (up to 72 hours in areas with poor transportation) Flow Wrapper Machine. If you fail to do so, you will be required to compensate for the loss of production suspension 48 per day.

Youdaoplaceholder0 Regional coverage : Priority will be given to local or neighboring provincial service providers (such as manufacturers in the Pearl River Delta radiating South China)

Ii. Technical Support capabilities

Youdaoplaceholder0 Professional team configuration

The proportion of certified engineers is no less than 80%, and they are familiar with PLC control, servo systems and membrane material characteristics Flow Wrapper Machine.

Remote diagnosis support: Lock fault codes (such as abnormal temperature control, photoelectric offset) within 0.5 seconds via video call 612 Flow Wrapper Machine.

Youdaoplaceholder0 Preventive maintenance system

Quarterly active inspection: Check for gearbox wear, bearing temperature rise, and aging of seals Flow Wrapper Machine.

Annual deep maintenance: Replace the silicone strip of the transverse sealing knife, clean the photoelectric sensor, and extend the equipment's service life by Flow Wrapper Packaging Machine 30%

V. Risk Avoidance Suggestions

Youdaoplaceholder0 Contract explicit penalty : Compensation for delayed response on a daily basis (it is recommended to agree on 5%-10% of the value of daily capacity) 5 Flow Wrapper Machine.

Youdaoplaceholder0 Verify service capacity :

Inspect the actual scene of the manufacturer's spare parts warehouse and confirm the depth of the regular spare parts inventory 7;

Request after-sales service records of customers in the same area (for example, an annual failure rate of no more than 3 times is preferred) Flow Wrapper Machine. 4

Youdaoplaceholder0 Summary : Quality after-sales service = 24-hour response × technical expertise × sufficient spare parts × proactive maintenance Before signing the contract, it is necessary to carefully check the vendor 's local service network and historical performance data