The selection of a suitable pillow packaging machine should be based on a comprehensive assessment of product characteristics, production efficiency, technical configuration and long-term costs Flow Packing Machine. The following is a systematic selection guide

1. Precisely match the product features

Youdaoplaceholder0 Physical properties fit

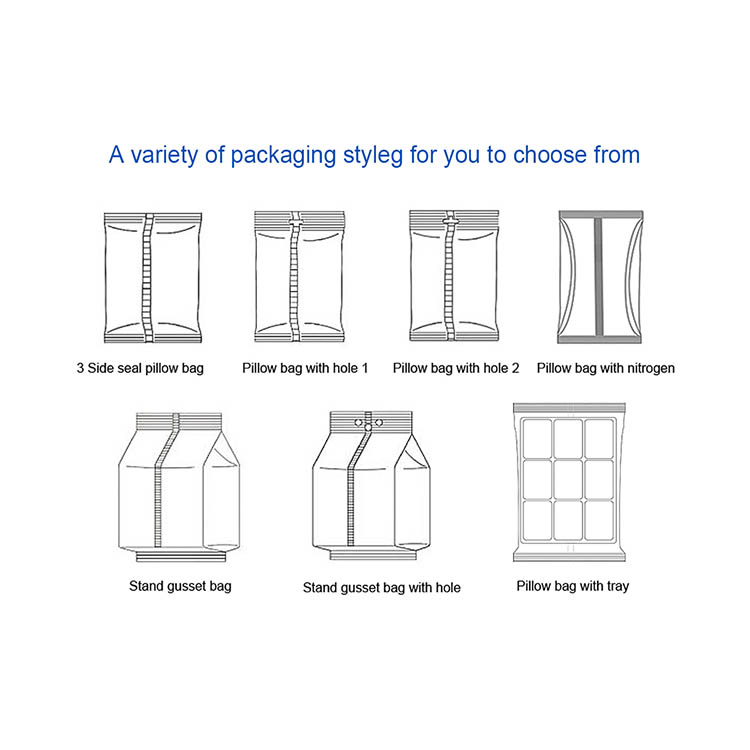

Youdaoplaceholder0 Regularity of shape : For regular long strip products (energy bars, cookies), horizontal pillow machine is preferred, with anti-offset clamping device 18; Irregular-shaped products (toys, hardware parts) require custom molds or the selection of flexible feeding systems. 7.

Youdaoplaceholder0 Special requirements :

Fragile items (coated energy bars) : Add a buffer inflation module, with a breakage rate of ≤0.3%8;

Sticky surface (chocolate) : Use Teflon anti-sticking hopper 1 Flow Packing Machine.

Youdaoplaceholder0 Industry compliance

Food/Medicine: Select 304 stainless steel body, pass GMP/FDA certification, and have dust-proof sealing design 26 Flow Packaging Machine;

Industrial products: Motor power ≥2.2kW, reinforced load-bearing structure Flow Packing Machine.

Iii. Intelligence and Compatibility

Youdaoplaceholder0 Control system

Mandatory servo drive, supporting one-click model change and parameter memory, mold change time < 15 minutes 610;

The 10-inch touch screen integrates self-diagnosis of faults (0.5-second alarm) 11 Flow Packing Machine.

Youdaoplaceholder0 Expandability

Modular design: Quick replacement of formers/cutters, suitable for products with size differences > 20% 27;

Support MES integration: Achieve production data traceability (mandatory requirements for pharmaceuticals/food)

Youdaoplaceholder0 Cost control

Payment ratio: 30% advance payment +60% acceptance payment +10% warranty deposit (including warranty for wear parts) 3;

Avoid the low-price trap: Calculate the full life cycle cost (energy consumption + maintenance), and prioritize the source factory 57 Flow Packing Machine.

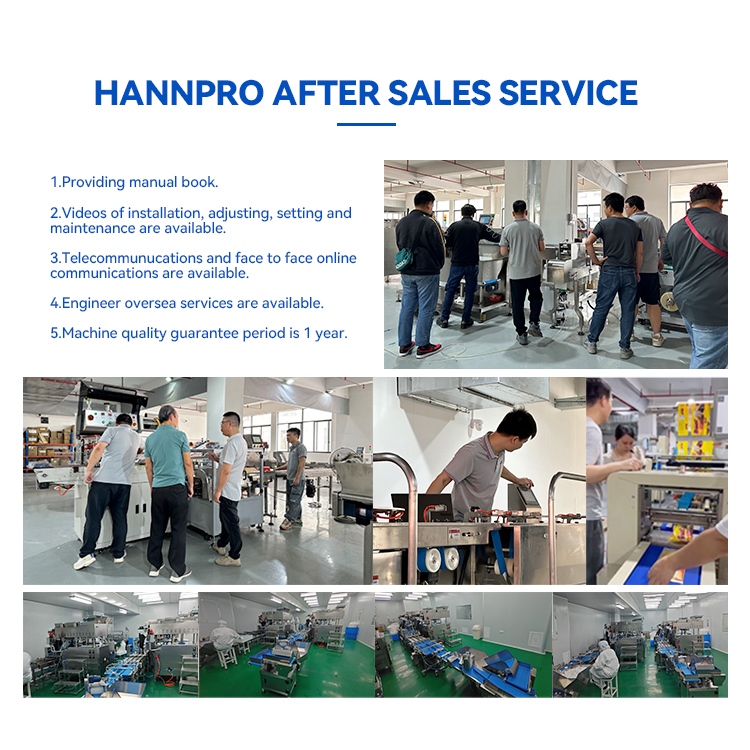

V. Verification and After-sales Support

Youdaoplaceholder0 Field verification

The test with materials was conducted for more than 72 hours, and the box jamming rate was less than 1‰ Flow Machine.

Check the laser cutting accuracy and gearbox process 5 Flow Packing Machine.

Youdaoplaceholder0 After-sales terms and conditions

Clarify the response time (such as 24-hour on-site service), and the warranty covers core components 35.

Prioritize local service providers to shorten the maintenance cycle by 8 Flow Packing Machine.

Youdaoplaceholder0 Key Tip : When the product size difference is too large (e.g. < 10cm candy vs > 30cm bread), the extension configuration is more economical and efficient than the "universal model" 12.

The precise measurement of pillow packaging machines mainly relies on the high-precision measurement system they are equipped with Flow Packing Machine. This system selects different measurement methods based on the different characteristics of the packaged materials (such as solids, granules, powders or liquids). The following are several common measurement methods and their working principles:

Volumetric metering

It is suitable for granular or powdered materials. The quantity of material filled each time is controlled by adjusting the volume size. For instance, the screw metering device uses a spiral propulsion method to push the material out. By adjusting the screw's rotational speed and the number of rotations, the output of the material can be precisely controlled.

2. Weighing measurement

For products that require more precise weight control, weighing metering devices can be adopted. This kind of system usually includes an electronic scale, which can accurately measure the weight of the material before it is added to the packaging bag, and automatically adjust the addition amount through the feedback control system to ensure that the weight of the product in each package is consistent Flow Packing Machine.

3. Counting measurement

When dealing with small items of fixed size (such as pills, capsules, etc.), counting measurement is an ideal choice. This method uses photoelectric sensors or other detection means to count the passing items to ensure that each package contains a preset number of items Flow Packing Machine.

4. Flowmeter measurement

It is mainly used for packaging liquid products. The flowmeter can measure the volume of liquid flowing through the pipeline and determine the filling volume accordingly Flow Packing Machine. To enhance accuracy, servo motors are sometimes used in combination to drive the pump body, in order to better control the speed and total volume of the liquid flowing out.