The Pillow Packing Machine is a fully automatic horizontal packaging equipment .

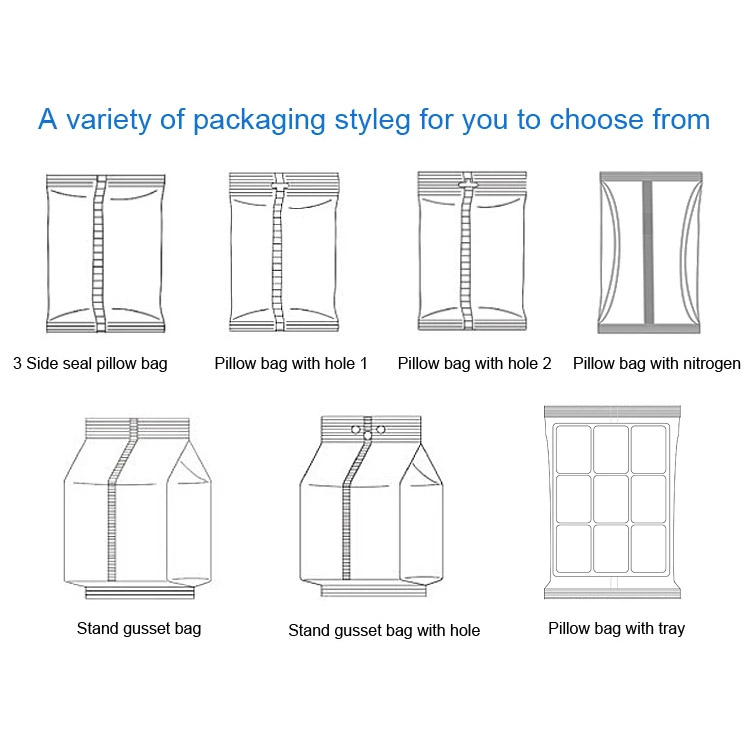

It is an industrial machinery that wraps products into pillow-shaped three-dimensional bag shapes (pillow-shaped Package) through continuous bag-making, filling and sealing processes Flow Pack Packaging Machines. The following is its technical definition and core feature decomposition:

I. Core Definitions

Youdaoplaceholder0 Basic principles

Youdaoplaceholder0 Horizontal continuous bag-making : The film (roll) moves horizontally and is rolled into a tube by the forming machine Flow Packaging Machines. The product is pushed laterally into the film tube, and the longitudinal (middle seam) sealing and transverse (end sealing) cutting are completed simultaneously 39 Flow Pack Packaging Machines.

Youdaoplaceholder0 Pillow structure formation : The cross-sealing knife cuts while clamping the membrane cylinder to form symmetrical pillow bags with closed ends (length-to-diameter ratio is usually ≥1.5)

Iii. Typical Application Scenarios

Youdaoplaceholder0 Applicable product form

Youdaoplaceholder0 Regular solids : Rigid/semi-rigid items such as energy bars, cookies, medicine plates, batteries, etc. with a length-to-diameter ratio greater than 1 39 Flow Pack Packaging Machines.

Youdaoplaceholder0 Size range : length 50-300mm, diameter/thickness ≤80mm (Extra specification required)

Note : Not applicable to liquids, powders and ultra-thin brittle products (such as potato chips)

Youdaoplaceholder0 Summary definition :

The pillow packaging machine is a standardized industrial equipment that takes horizontal continuous bag-making - horizontal sealing and cutting as its core process Flow Pack Packaging Machines. Through photoelectric positioning, heat sealing control and precise transmission system, it realizes fully automatic pillow-shaped sealing packaging for regular solid products. Its technical core lies in the synchronous sealing and cutting accuracy and the adaptability of film materials .

I. Core Functions and Technical Principles

Youdaoplaceholder0 Precision sealing and cutting system

The photoelectric positioning error compensation technology (advance and retreat type/braking type/synchronous type) is adopted. The position deviation of the sealing and cutting under high-speed operation (200 packets per minute) is ≤0.5mm.

The reciprocating sealing system is suitable for products of different heights and lengths Flow Packing Machines, and its sealing flatness is superior to that of the rotary design 410 Flow Pack Packaging Machines.

Youdaoplaceholder0 Intelligent control module

The dual frequency converter drive enables the bag length to be "set and cut immediately", reducing the type change time to 3 minutes and increasing the membrane material utilization rate by 12%.

The 10-inch touch screen interface supports over 20 parameter adjustments and integrates self-diagnosis of faults (0.5-second alarm) and positioning shutdown functions Flow Pack Packaging Machines.

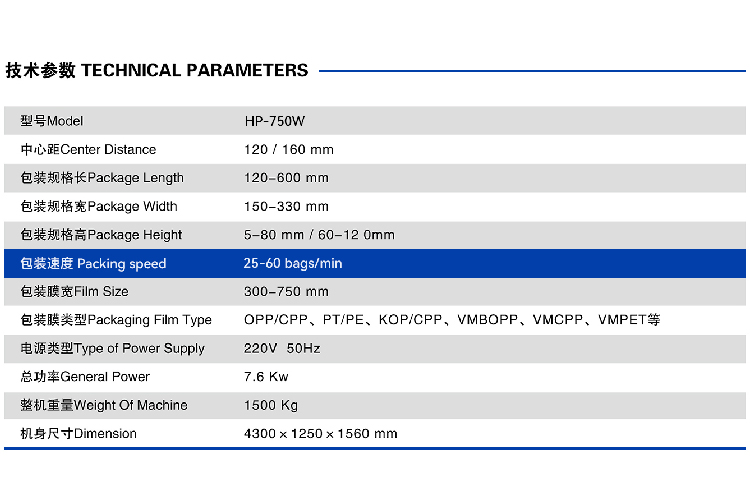

Iii. Key Performance Indicators

Youdaoplaceholder0 Accuracy and efficiency

The positioning accuracy of the servo system is ±1mm, and the temperature control accuracy is ±2℃ (PID algorithm matching PE/OPP/ aluminum film). 8 Flow Pack Packaging Machines.

Continuous operation MTBF≥2000 hours, transmission noise ≤65dB68.

Youdaoplaceholder0 Safety compliance

The contact parts are made of 304 stainless steel, in compliance with FDA/GMP and the new national standard of 2024 (such as GB/T 22747-2022) 912.

Emergency stop button, protective door and overload protection triple protection 6 Flow Pack Packaging Machines.

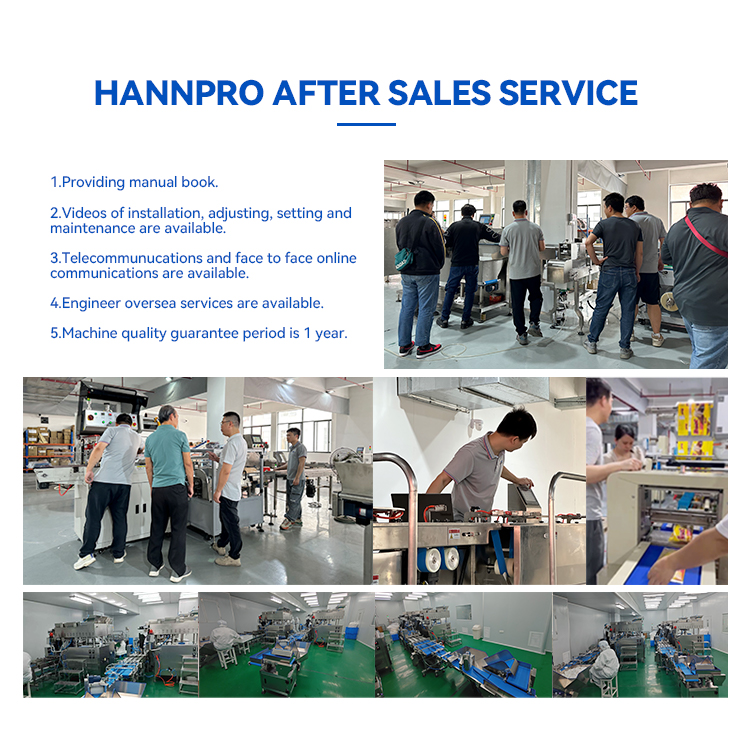

Iv. Procurement and Maintenance Strategies

Youdaoplaceholder0 Supplier screening

Check the factory's processing technology (such as laser cutting accuracy), and require a 72-hour material test report 5 Flow Pack Packaging Machines.

Priority domestic brands: Yongchuang Intelligent (complete line solution), Guchuan Machinery (high-precision servo), Hualian Machinery (QS/GMP certification)