The automatic packaging machine for energy bars is a specialized device designed for the automated sorting, conveying, weighing and packaging of energy bar products, and is suitable for large-scale production of energy bars. This kind of machine can significantly improve production efficiency, reduce manual operations, and ensure the hygiene and safety of products Energy Bar Packing Machine.

The following is a comprehensive information summary about the automatic pa ckaging machine for energy bars, combining key dimensions such as equipment types, manufacturer distribution, technical parameters, and market quotations:

o I. Core equipment types and technical characteristics

o Pillow packaging machine

Applicable scenarios: Individual packaging of independent energy bars (such as chocolate-coated bars, grain bars)

Technical highlights:

Electric furnace wire heating technology (3-minute rapid heating, temperature control fluctuation ±5℃)

Precise sealing and cutting of trademark film (error ≤1mm) Energy Bar Packing Machine

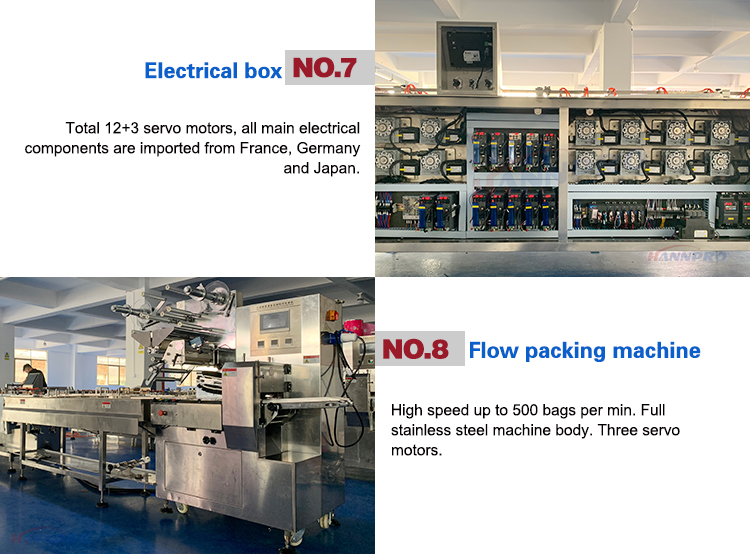

Speed range: 30-300 packets per minute (dual frequency converter speed regulation)

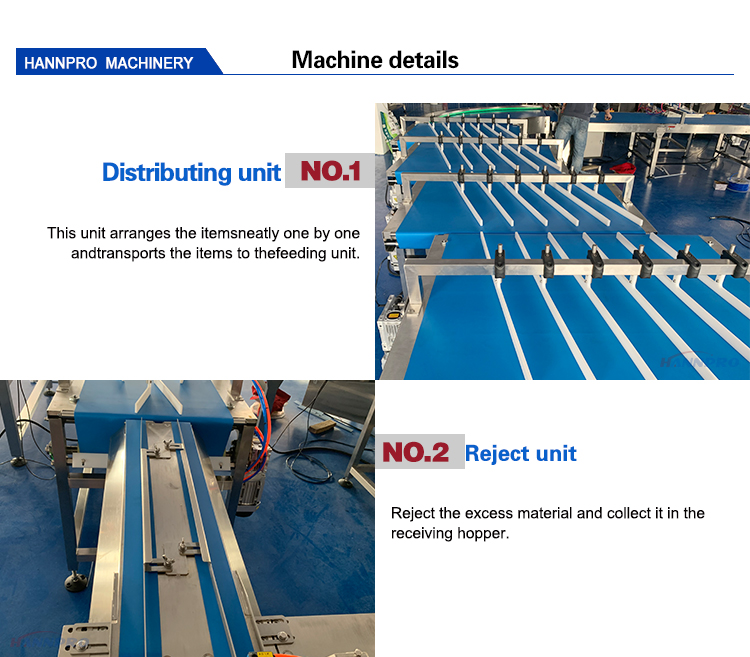

o Disc sorting line + automatic packaging system

Function: Integrated high-speed material sorting, arrangement, nitrogen filling and packaging Energy Bar Packing Machine.

Typical applications: High-capacity scenarios such as protein bars and cheese slices (supporting dual-channel operation)

Efficiency: Up to 1000 pieces per minute (subject to product size adjustment) Energy Bar Packing Machine

Extrusion molding and coating equipment

Extruder: Used for shaping raw cat food/energy bars (price approximately ¥9,800)

Chocolate coating machine: Fully automatic chocolate coating + insulation system (price approximately ¥16,000)

Iii. Key technical parameters

o Applicable product specifications :

Dimensions: 10-100mm (length) ×10-50mm (width) ×5-30mm (height) Energy Bar Packing Machine

Weight: 1-100g11

o Packaging material compatibility : polyethylene film, aluminium foil, pre-printed trademark film

o Control system : PLC+ touch screen with automatic shutdown protection Energy Bar Packaging Machine

o Energy consumption : AC 220V/50Hz, power about 2KW Energy Bar Packing Machine

o IV. Industry Trends and Innovation solutions Energy Bar Packing Machine

o Smart metering technology :

For block/granular materials, computerized combined scales (with weight error ≤0.5g) are adopted.

The filling of sauce relies on the screw extrusion system (solving the problem of solid-liquid mixing)

o High-Speed development : Double-pass material production line increases capacity by 30%, especially suitable for the production of e-commerce bestsellers

1. Core selection logic Energy Bar Packing Machine

o Product features fit

o Shape matching : Regular rod priority pillow packaging machine (standard with automatic material line), irregular/coated products require custom mold or add anti-stick module

o Weight accuracy : ≤1g error optional dynamic weighing system (such as servo screw packing), > 50g energy bar gravity sensor measurement recommended

o Special protection : Coating anti-sticking requires Teflon hopper Energy Bar Packing Line, brittle product with buffer gas filling device (breakage rate can be reduced to 1.5% or less)

2. Equipment performance hard indicators

o Precision control :

The sealing and cutting positioning error is ≤1mm (synchronous photoelectric deviation correction system is required)

Measurement fluctuation ≤±0.5% (It is recommended to select a computerized combined scale)

o Stability verification :

Continuous 72-hour full-load test (failure rate < 0.5%)

Temperature control fluctuation within ±5℃ (essential for chocolate coating)

o Degree of intelligence :

Support MES system integration (real-time monitoring of OEE)

Self-diagnosis of faults (more than 90% of common problems can be remotely repaired)

o Site inspection 4 key points :

Workshop cleanliness (Food grade requires GMP-certified workshops)

Measured material thickness (stainless steel of the body ≥2mm)

On-site packaging of one's own products for testing (prototype demonstrations are refused)

Emergency fault response time limit (The contract specifies 4 hours of remote support)

o IV. Solutions for special conditions

o Coating adhesion : Add cold air shaping module (cost +15%)

o Fragile structure : Equipped with air pressure buffer guide rails (Packaging breakage rate ↓80%

o e-commerce small order Fast response : Modular design model (change time < 15 minutes)

o Execution suggestion : Give priority to manufacturers that offer payment terms of 30% advance payment +60% acceptance payment +10% warranty deposit , and reserve the right to conduct small-scale test machines (such as leasing prototypes to verify compatibility)