The bottom-walking film pillow packaging machine is a specific type of pillow packaging machinery horizontal wrapping machine.

It completes the wrapping of products by feeding the packaging film from the bottom flow wrap packing machine. This design is particularly suitable for some products that require special packaging processes or hope to reduce the operation space of packaging materials above. The design of the bottom-running film helps keep the working area clean and tidy, and in some cases, it can improve packaging efficiency and quality.

Main features

Compact structure: As the packaging film enters from the bottom of the machine, this helps save space above the equipment horizontal flow wrap machine, making the overall layout more compact horizontal wrapping machine.

Cleanliness and hygiene: For industries such as food and medicine that have high requirements for hygiene conditions, the bottom-walking film method can effectively prevent dust or other impurities from settling on the packaging film, ensuring product hygiene horizontal wrapping machine.

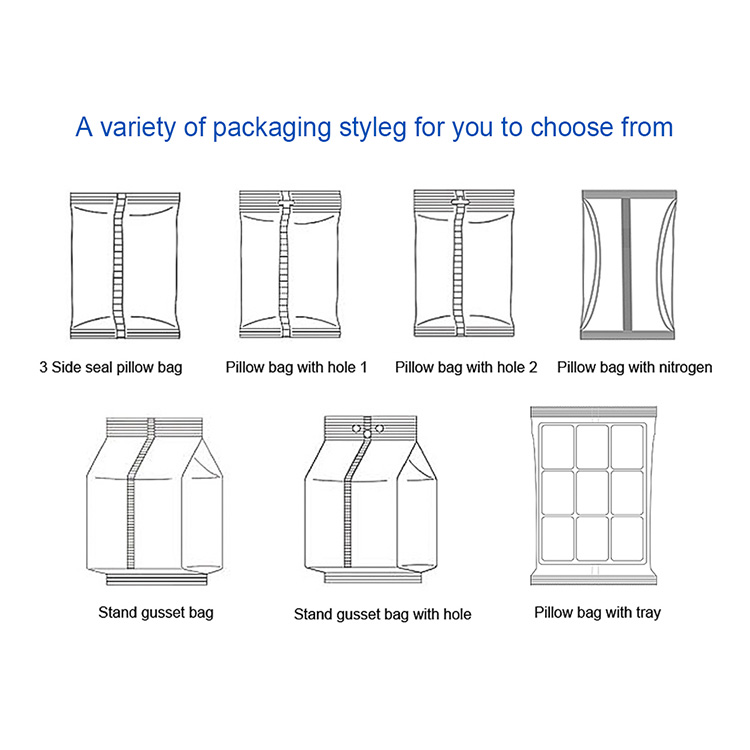

Strong adaptability: It can handle products of various shapes and sizes, including solid, granular, and blocky items, etc flow packaging machine.

Easy to maintain: The design usually takes into account ease of maintenance, facilitating daily cleaning and troubleshooting horizontal wrapping machine.

Working principle

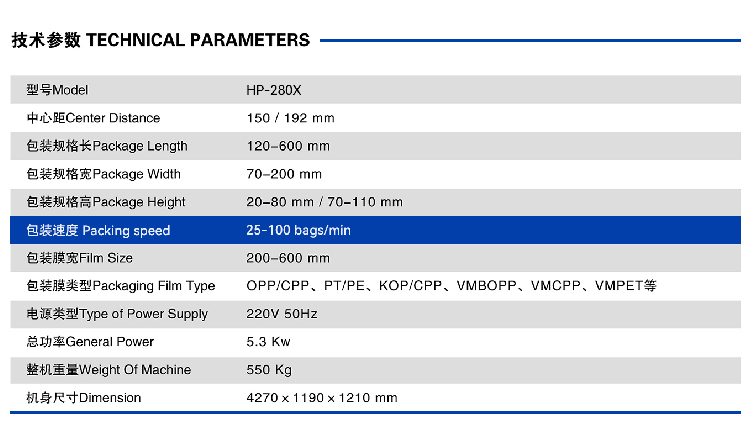

The working process of the bottom-walking film pillow packaging machine is similar to that of the traditional pillow packaging machine, with the main difference lying in the conveying path of the packaging film flow wrap packing machine. First, the packaging film is pulled out from the bottom of the machine, passes through the mold to form a bag shape, then the product is pushed into the bag, followed by sealing the bag through the heating sealing system, and finally cut into individual packages according to the set length. Servo motors are often used to control the precise execution of these steps to ensure the consistency and aesthetic appeal of each package horizontal wrapping machine.

Scope of application

This type of packaging machine is widely used in industries such as food, medicine, and daily chemicals, and is particularly suitable for application scenarios with high requirements for the packaging environment, such as food packaging and medicine packaging that need to prevent external contamination horizontal wrapping machine.

The bottom-running film design in pillow packaging machines has multiple advantages in improving packaging quality, as follows:

Improving packaging cleanliness: As the packaging film is fed from the bottom of the machine, during the packaging process, the film material is directly pulled up from below to wrap the product. This reduces the chance of the film material coming into contact with the external environment and lowers the possibility of dust, impurities and other contaminants adhering to the film, thereby ensuring the cleanliness and hygiene standards of the packaging.

Enhance packaging accuracy: The design of the bottom-running film helps maintain the consistency of the film material tension, enabling the packaging material to adhere more smoothly to the shape of the product. This precise control is crucial for achieving high-quality sealing and an aesthetically pleasing packaging appearance horizontal wrapping machine.

Optimizing packaging efficiency: By optimizing the film material path, the friction and resistance of the film material during transmission can be reduced, thereby accelerating the packaging speed. At the same time, it can also lower the loss rate of the film material and improve the overall production efficiency horizontal wrapping machine.

Adapt to complex packaging requirements: For some irregularly shaped or heavy products, the bottom-running film design can better adapt to these special circumstances, providing stable support and wrapping to ensure that each product is properly packaged.

Easy to maintain and operate: The underpass membrane structure is usually designed to be more intuitive, making it easy for operators to carry out daily maintenance and troubleshooting. For instance, it is more convenient and faster to change the film rolls or adjust the parameters, reducing downtime and enhancing the overall efficiency of the production line.

In conclusion, the bottom-running film design not only helps to enhance the quality and aesthetic appeal of packaging, but also increases production efficiency and meets more stringent hygiene standards. It is particularly suitable for high-demand packaging tasks in industries such as food and medicine horizontal wrapping machine.