Regarding the "Coffee Bar single-column packaging Machine", this is a device specifically designed to arrange coffee bars (such as instant coffee bars, coffee capsules, etc.) in a single column and complete automatic packaging Coffee Stick Packing Machine. This type of equipment is typically applied in the automated production lines of the food and beverage industry, capable of achieving functions such as automatic feeding, metering, filling, sealing, date printing, and finished product output Coffee Packing Machine.

The following is the relevant introduction about the coffee strip single-column packaging machine:

Working principle

Measurement principle: Usually, spiral filling measurement or negative pressure filling measurement is adopted. The spiral filling and packaging machine conveys and measures coffee powder through the rotation of the screw, and the measurement accuracy depends on the processing accuracy of the screw. The negative pressure filling and packaging machine combines the volumetric method and the weighing method. It first uses negative pressure to suck up a certain volume of coffee powder, and then precisely measures it through weighing Coffee Packing Machine.

The principle of bag-making and sealing: The packaging machine pulls the rolled packaging material over, and through the forming machine, it is made into a cylinder shape, and then longitudinally sealed to form the side seal of the bag Coffee Stick Packing Machine. Next, after filling the bag with coffee grounds, it is sealed horizontally to complete the sealing at the bottom and top. Finally, it is cut off to form individual coffee stick bags Coffee Packing Machine.

Structural composition

Feeding mechanism: It is used to transport coffee grounds from storage containers to metering devices. Common types include vibrating feeders and screw feeders, which can ensure a uniform and stable supply of coffee grounds Coffee Packing Machine.

Measuring devices: such as screw meters, electronic scales, etc., precisely measure coffee grounds to ensure that the amount of coffee grounds in each packet meets the set standard Coffee Stick Packing Machine.

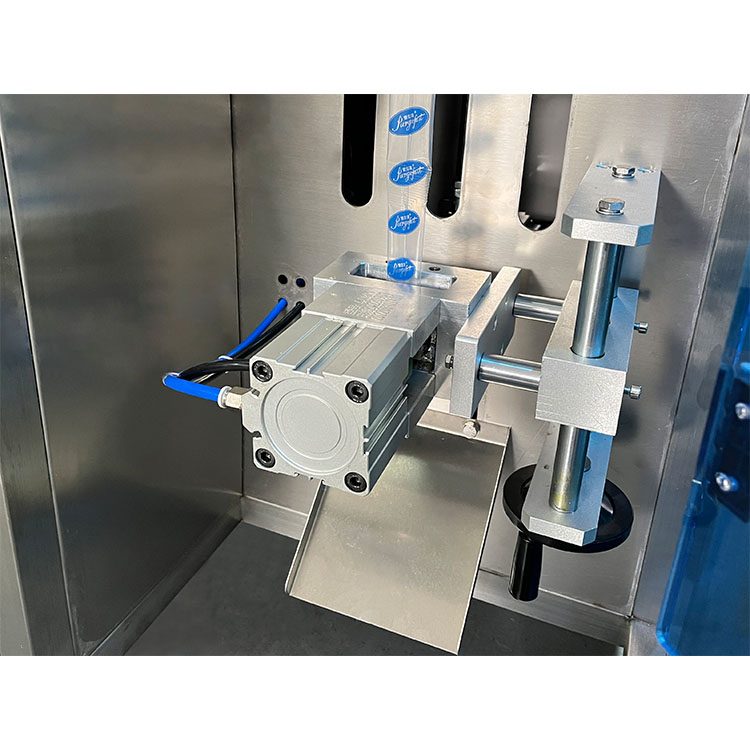

Bag-making and forming mechanism: It includes a forming device, longitudinal sealing device and transverse sealing device, etc., to form packaging materials into bags and seal them Coffee Packing Machine.

Cutting mechanism: After the sealing is completed, the continuous coffee strips are cut into individual coffee strips Coffee Stick Packing Machine. The cutting methods include hot cutting, cold cutting, etc.

Control system: Generally composed of single-chip microcomputers or PLCS and other controllers Coffee Stick Packing Machine, it realizes the overall control of the packaging machine, including the coordinated operation of various links such as metering, bag making, sealing, and cutting. It can also perform functions such as parameter setting and fault diagnosis Coffee Packing Machine.

Performance characteristics

High packaging accuracy: By adopting advanced measurement technology and control systems, the filling amount of coffee grounds can be precisely controlled, with errors kept within a small range, ensuring that the weight of each bag of coffee is consistent Coffee Packing Machine.

Fast speed: It has a relatively high packaging speed, typically capable of packaging 20 to 50 bags per minute, which can meet the needs of coffee production enterprises of different scales Coffee Powder Packing Machine.

Wide application range: It is not only suitable for packaging coffee powder, but also for packaging other powder or granular materials such as milk powder, chocolate powder, and flavoring powder.

The packaging forms are diverse: It can achieve various sealing forms such as back sealing, three-side sealing, and four-side sealing Coffee Stick Packaging Machine. It can also be made into coffee stick bags of different shapes and sizes according to requirements Coffee Powder Packing Machine, such as rectangular and rounded corner shapes Coffee Packing Machine.

High degree of automation: It can automatically complete a series of packaging processes such as feeding, metering, bag making, filling, sealing and cutting, reducing manual operation, improving production efficiency and packaging quality, and lowering labor intensity Coffee Stick Packing Machine.