The automatic boxing and packaging line for laundry detergent is a highly automated production system bottle case packer, specifically designed to automatically perform a series of operations such as packaging, boxing, and sealing of finished laundry detergent from the end of the production line robotic bottle case packer.

This packaging line has significantly enhanced production efficiency, reduced manual intervention, and ensured the consistency of packaging and the safety of products. The following are some of the main components and technical features of the automatic box packaging line for laundry detergent:

Main components

Filling machine: Firstly, it accurately fills liquid products into bottles or containers pet bottle case packer.

Sealing machine: Seals containers containing laundry detergent to ensure no leakage during transportation and storage bottle case packer.

Labeling machine: It adheres labels to the surface of containers bottle case packer, including necessary information such as brand details, ingredient descriptions, and usage methods.

Inkjet printer/coding machine: Add traceability marks such as production date and batch number to each product glass bottle case packerbottle case.

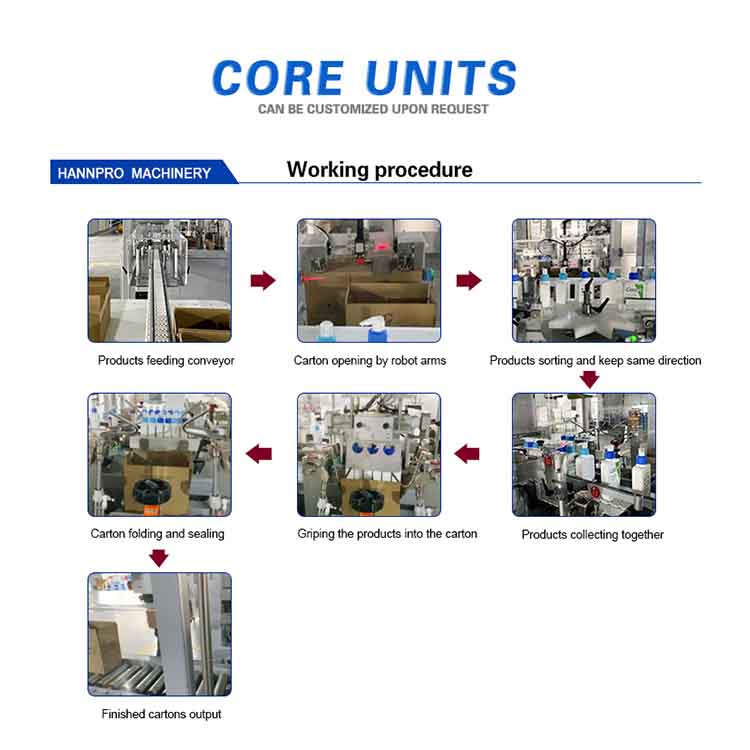

Automatic case packing machine: Collect and neatly arrange multiple finished containers bottle case packer, and then load them into cartons. This process can be adjusted as needed to accommodate cartons of different specifications and product quantities.

Carton sealing machine: Seals cartons filled with products to ensure their integrity during the logistics process bottle case packer.

Palletizing robot: Stacks the sealed cartons according to the predetermined pattern bottle case packer machine, preparing for subsequent storage or transportation.

Technical characteristics

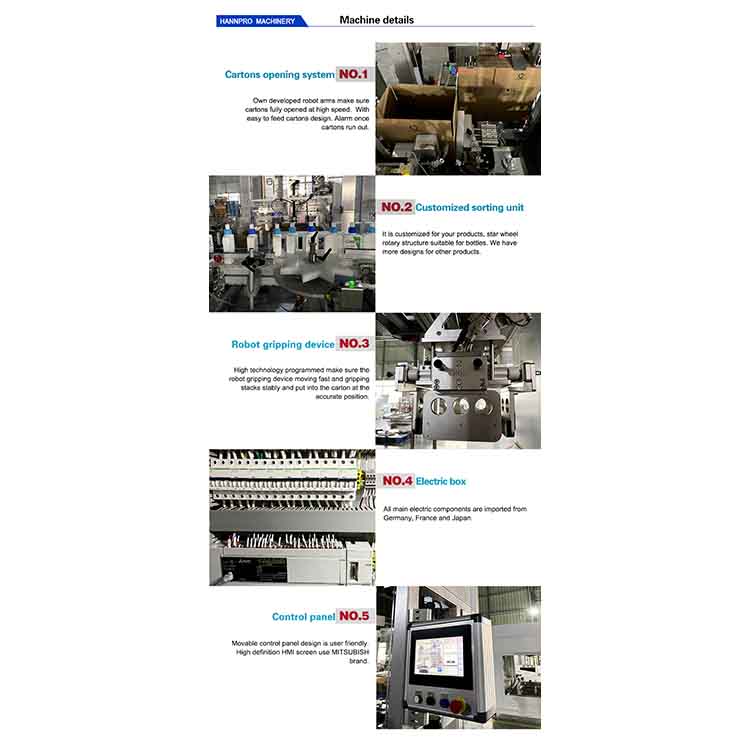

High degree of automation: The entire process requires almost no human intervention bottle case packer, greatly enhancing production efficiency and product quality.

High accuracy: Whether it is the filling volume, sealing quality or labeling position bottle case packer, they can all remain highly consistent.

Good flexibility: It can be quickly adjusted to meet the requirements of products of different specifications and packaging bottle case packer.

Intelligent control system: It adopts advanced PLC or PC control systems, and some even integrate Internet of Things technology, enabling remote monitoring and data analysis.

Safety and hygiene: The equipment was designed with food safety standards in mind bottle case packer, avoiding the risk of product contamination.

Application advantages

Improve production efficiency and reduce labor costs.

Ensure packaging quality and consistency to enhance the brand image bottle case packer.

Realize flexible production and respond quickly to market changes.

Improve the working environment and reduce the labor intensity of employees.

When choosing an automatic laundry detergent box packaging line that suits their own needs bottle case packer, enterprises should comprehensively consider factors such as their production capacity, budget constraints, and future expansion plans. With the development of automation technology and intelligent manufacturing, the functions and performance of such packaging lines are constantly improving, providing more possibilities for enterprises.

The latest developments in intelligent packaging line technology focus on enhancing efficiency, flexibility, environmental friendliness and intelligence levels, etc. The following are several key development trends:

Intelligence and the Internet of Things (IoT)

Intelligent packaging lines are increasingly integrating Internet of Things (iot) technology, which monitors the equipment status in real time, collects data and conducts analysis through sensors and network technology.

Utilize big data analysis to optimize the production process bottle case packer, issue early warnings of potential problems, and carry out preventive maintenance.

Artificial Intelligence (AI) and Machine Learning

AI technology is employed to optimize the workflow of packaging lines bottle case packer, such as automatically adjusting packaging speed and material selection in response to changes in the production environment.

The automatic recognition of products is achieved through image recognition technology to ensure that each product can be accurately packaged.

Enhanced flexibility

The packaging line can now quickly adapt to the packaging requirements of products of different specifications and shapes, meeting the market's demand for personalized products.

The automation system can support the packaging of multiple products on the same assembly line bottle case packer, improving the universality and response speed of the production line.

Green and environmentally friendly

Emphasize the use of recyclable materials and environmental protection technologies bottle case packer, such as packaging with biodegradable materials, to reduce the impact on the environment.

Improve the energy efficiency of equipment bottle case packer, reduce energy consumption, and help enterprises achieve sustainable development goals.

The application of blockchain technology

Blockchain technology is used to enhance the transparency and immutability of product information, strengthening anti-counterfeiting capabilities and consumer trust.