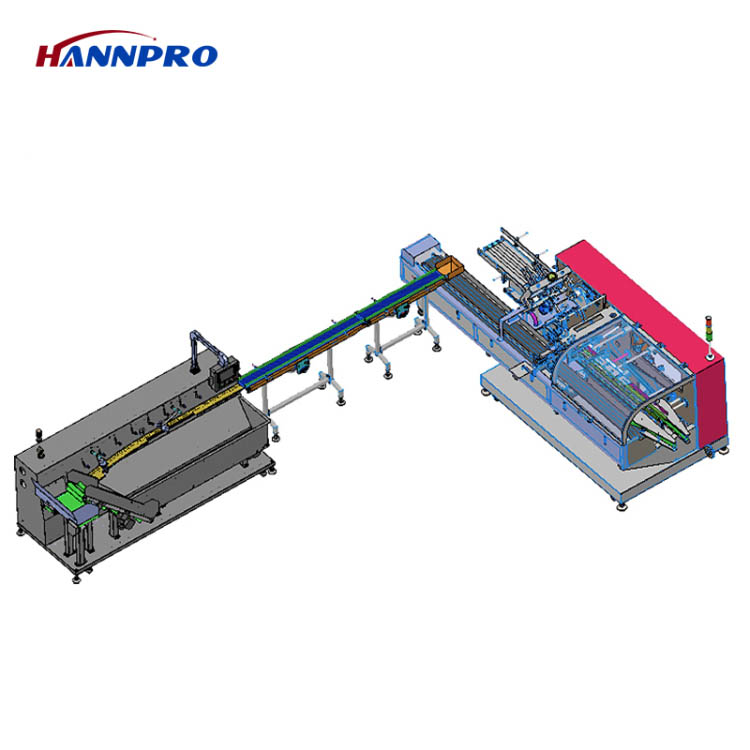

Disorderly bag sorting, counting, boxing and packaging line

I. Basic Concepts

The disordered bag arrangement, counting and boxing packaging line is an automated packaging production line for bagged products (such as food, medicine, daily necessities, etc.), mainly used to address the core demands of "disordered arrangement, precise counting, automatic filling and automatic boxing" during the packaging process of bagged products sachet sorting machine.

This production line integrates multiple automated devices to achieve full-process automation from the sorting, counting, boxing to the final packaging of bagged products, significantly enhancing production efficiency and packaging accuracy, and reducing manual intervention sorting machine.

Ii. Core Component Modules and Functions

The production line is usually composed of the following key equipment modules sachet sorting machine, which work together to achieve full-process automation:

1. Bag arrangement unit

Function: Organize the randomly piled bagged products into an orderly arrangement, facilitating subsequent counting and boxing sachet sorting machine.

Equipment:

Bag arranging machine: Through the bag arranging machine: By means of devices such as vibration, conveyor belt or mechanical arm automatic sorting system, bagged products are laid flat or placed upright to eliminate stacking disorder sachet sorting machine.

Directional sorting device: It uses sensors (such as visual inspection, photoelectric sensors) to identify the direction of the bags, and unifies the orientation of the bags through mechanical levers or flipping mechanisms sachet sorting machine.

2. Counting unit

Function: Accurately count the orderly arranged bagged products to ensure the quantity of each box is accurate automatic sorter.

Technical solution:

Visual counting: By taking pictures of bagged products with high-speed cameras and using image recognition algorithms (such as deep learning and edge detection) to count the quantity, it is suitable for both transparent and non-transparent packaging bags, with high accuracy (error rate ≤0.1%) sachet sorting machine.

Photoelectric counting: By using multiple sets of through-beam photoelectric sensors, when the bag passes through, it blocks the light beam and counts through pulse signals. It is suitable for regular-shaped bags and has a relatively low cost.

Weighing and counting: The total weight is calculated through high-precision weighing sensors, and the quantity is inferred by combining the weight of each bag. It is suitable for fixed-weight products and requires regular calibration sachet sorting machine.

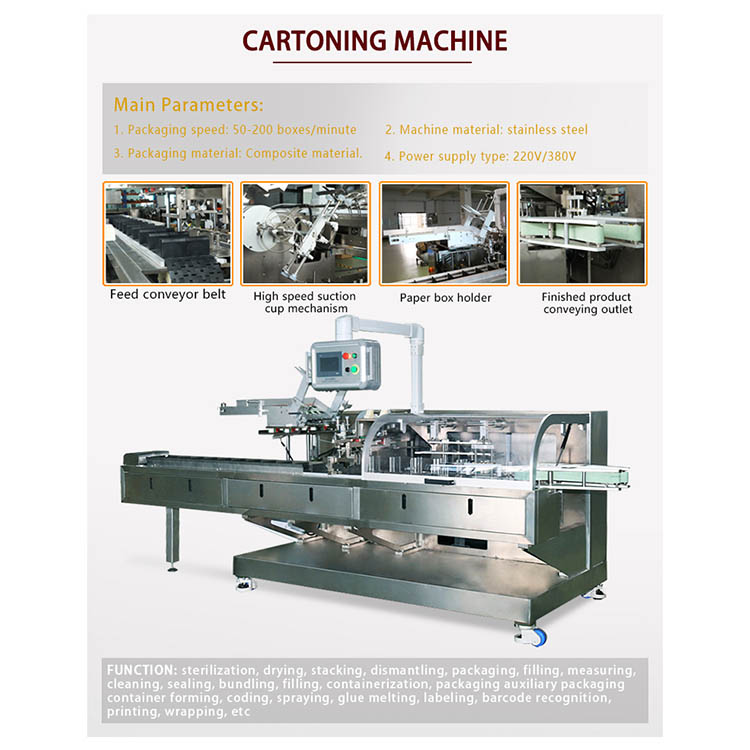

3. Boxing unit

Function: Load the counted bagged products into packaging boxes or cartons according to the set quantity automatic sorting machine.

Equipment:

Box opening machine: Automatically opens folded paper boxes to form regular box bodies and positions them at the box loading station sachet sorting machine.

Bag-pushing device: The bagged products are pushed into the box from the conveyor belt by mechanical push rods or suction nozzles. The movement is precise and gentle, avoiding damage to the products.

Box sealing machine: After bagging is completed, the box lid is automatically folded and sealed with hot melt adhesive, staples or clips. Some equipment supports simultaneous completion of inkjet coding or labeling sachet sorting machine.

4. Conveying and Control system

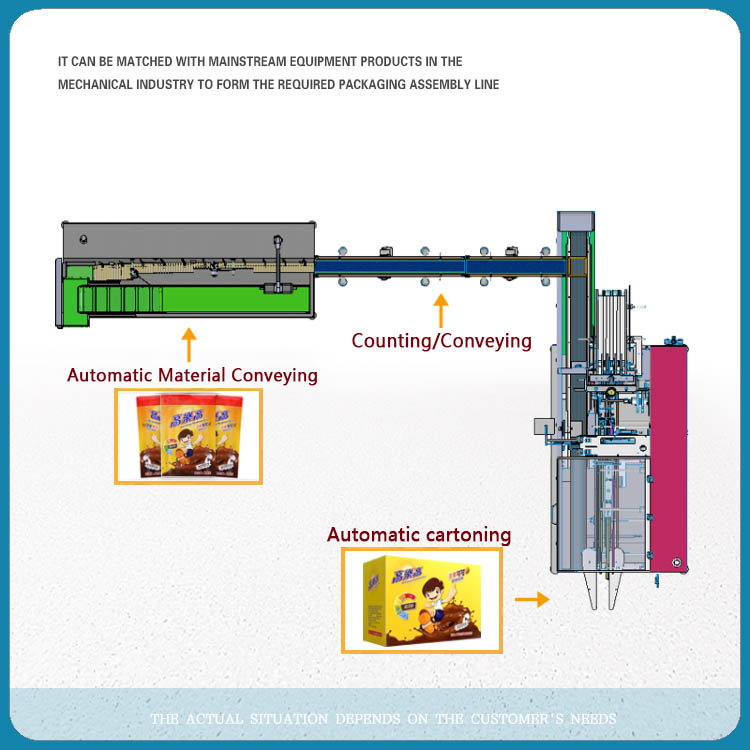

Conveying system

Conveyor belt: It adopts variable frequency speed regulation technology to connect each unit equipment, ensuring smooth bag transmission. The speed is adjustable (usually 0.5 to 5 meters per minute).

Sorting mechanism: Diverting single-row bags into multiple rows to match the number of cartoning workstations and enhance efficiency sachet sorting machine.

Control system

PLC (Programmable Logic Controller) : It coordinates the actions of various devices, monitors the status of the production line in real time, and supports fault alarm and parameter adjustment.

Human-machine Interface (HMI) : The operator sets production parameters (such as the quantity per box and packaging speed) through the touch screen and views the operation data sachet sorting machine.