The fully automatic cake packaging machine is a device specifically designed for the automated packaging of various types of cakes.

Automatic Cake Packing Machine can significantly enhance production efficiency, ensure product hygiene, and reduce labor costs. This type of equipment is usually applied to production lines in the baking industry and is capable of handling cakes of various shapes and sizes, including round, square, heart-shaped, etc.

Main functions

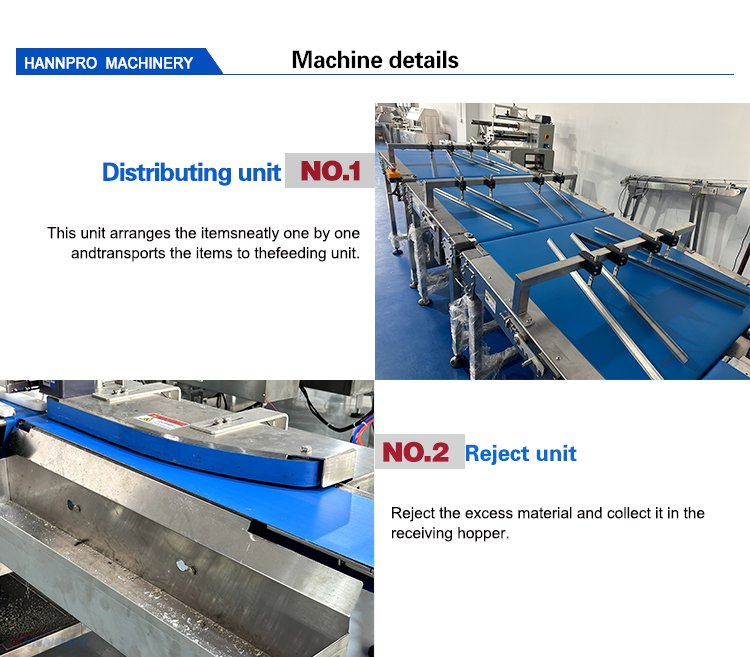

Automatic feeding: The cakes to be packaged are sent into the packaging machine from the production line or manual placement points.

Automatic sorting and arrangement: Adjust the position of the cakes according to the set requirements to ensure they are neatly arranged for subsequent operations Automatic Cake Packing Machine.

Automatic wrapping or bagging: Wrap the cake with plastic film or other packaging materials or put it in a bag Automatic Cake Packing Machine.

Sealing treatment: Heat sealing technology is adopted to seal the packaging bags to ensure the freshness and hygiene conditions of the food.

Print batch number/date: Print information such as the production date, shelf life or batch number on the packaging.

Cutting and separation: For continuous packaging, it is necessary to separate individual packaging items from the continuous packaging materials Automatic Cake Packing Machine.

Output finished products: After packaging, the cakes are conveyed to the designated location by the conveyor belt, ready to enter the next logistics stage.

Scope of application

Cakes of various sizes and shapes, such as birthday cakes, cupcakes, sliced cakes, etc.

Other similar pastries, such as pies, tarts, etc Automatic Cake Packing Machine.

Technical characteristics

Intelligent control: It mostly adopts PLC control systems and supports touch screen operation interfaces, which is convenient for parameter setting and monitoring.

High-precision sensors: used to detect the presence Cake Packaging Machine, location of cakes and the status of packaging materials Automatic Cake Packing Machine.

High-efficiency and energy-saving design: Optimize energy consumption to ensure work efficiency while reducing operating costs.

Safety protection measures: Equipped with emergency stop buttons and other safety devices to ensure the safety of operators.

Easy to clean and maintain: The parts that come into contact with food are usually made of stainless steel, which is convenient for cleaning and disinfection Automatic Cake Packing Machine.

Choosing a cake packaging machine that suits your production capacity requires a comprehensive consideration of multiple factors to ensure that the selected equipment can meet your production needs and provide good economic benefits in the long-term operation Automatic Cake Packing Machine. The following are some key points:

Determine the production demand:

First, clarify the number of cakes you need to package daily or per hour Automatic Cake Packing Machine. This will help you determine the required packaging speed (packages per minute).

Consider the growth expectations in the coming years and select machines with appropriate margins.

Understand the product features:

Cakes of different shapes and sizes may require different packaging solutions Automatic Cake Packing Machine. For example, round, square, heart-shaped cakes and cupcakes, etc. may require specially designed feeding systems and packaging molds.

Determine whether it is packaged separately or in multiple pieces Cake Packaging Machine, as this will also affect the choice of packaging machine.

Selection of packaging materials:

Select appropriate packaging materials (such as plastic films, paper boxes, etc.) based on the characteristics of the product and market demand Automatic Cake Packing Machine. The choice of packaging materials will affect the functional configuration of the machine (such as heat sealing and cold sealing technologies).

Degree of automation

The fully automatic packaging machine can significantly improve efficiency and reduce labor costs, but the price is also relatively high. For large-scale production, investing in fully automatic equipment might be a more economical choice Automatic Cake Packing Machine.

If it is small-scale production or the budget is limited Cake Packaging Machine, semi-automatic equipment can be considered as a transitional solution.

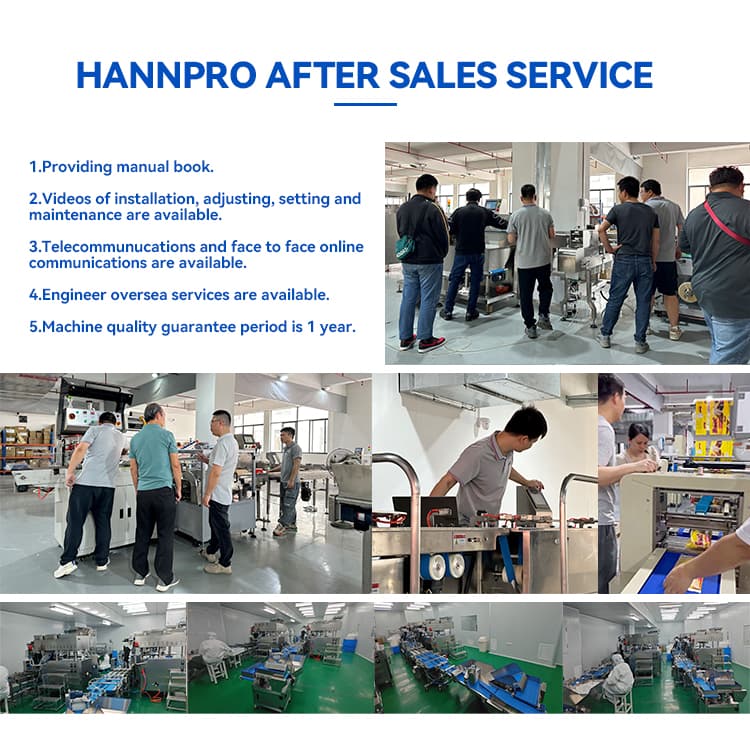

Technical support and services:

Choose those brands and suppliers that offer good after-sales service Automatic Cake Packing Machine. Timely technical support can help solve problems encountered during use and avoid unnecessary downtime.