Overview of the Automatic Sorting and One-time Packaging Line for Biscuits

The automatic sorting and one-time packaging line for biscuits is a key equipment for achieving automated biscuit production in the food processing industry Automatic Biscuit Packing Line. It is mainly used to complete core processes such as biscuit sorting, counting, and packaging.

It features high efficiency, accuracy, and hygiene, which can significantly enhance production efficiency and reduce labor costs Biscuit Packaging Line. The following is a detailed introduction from aspects such as system composition, workflow, core technologies, advantages and application scenarios Automatic Biscuit Packing Line.

I. System Composition

The automatic sorting and one-time packaging line for biscuits is usually composed of multiple functional modules working together Automatic Biscuit Packing Line, with each module having a clear division of labor to ensure the smooth operation of the production line:

1. Conveying unit

Function: Transport the baked cookies from the front end of the production line to the sorting and packaging stations Automatic Biscuit Packing Line.

Equipment:

Mesh belt conveyor: Used for transporting biscuits to prevent sticking (suitable for crispy biscuits) Biscuit Packaging Line.

Chain plate conveyor: It can carry heavy or irregular-shaped biscuits and has strong stability Automatic Biscuit Packing Line.

Incline conveyor: Connects workstations of different heights (such as from the oven to the sorting table).

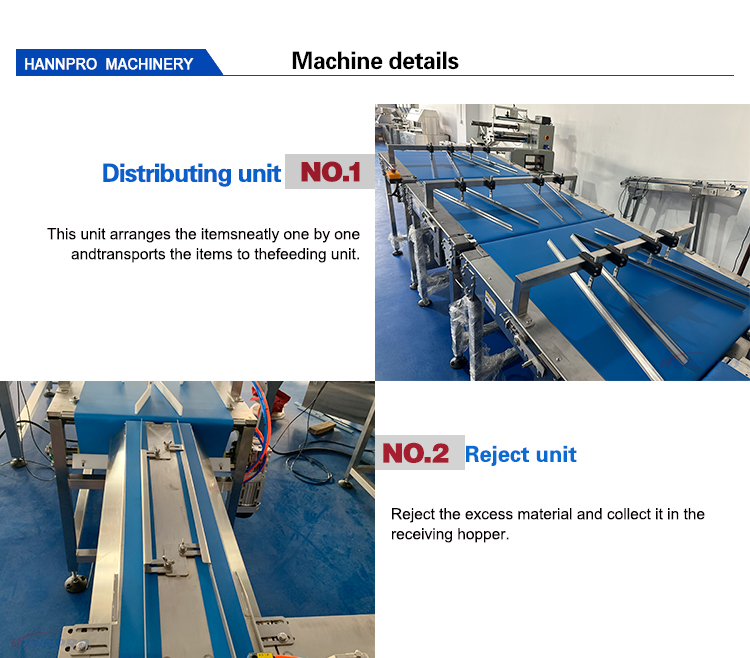

2. Sorting unit

Function: To conduct quality inspection, shape screening and counting grouping of biscuits.

Equipment:

Visual inspection system: Through cameras and image processing technology, it identifies defects such as the size, color, and missing corners of biscuits, and eliminates substandard products Automatic Biscuit Packing Line.

Sorting manipulator/air-blowing device: Based on the test results, the substandard biscuits are removed by the mechanical arm's grasping or air flow conveying method Automatic Biscuit Packing Line.

Counting device: Qualified biscuits are counted by photoelectric sensors or weighing modules and grouped according to the preset quantity (such as 50 biscuits per bag) Automatic Biscuit Packing Line.

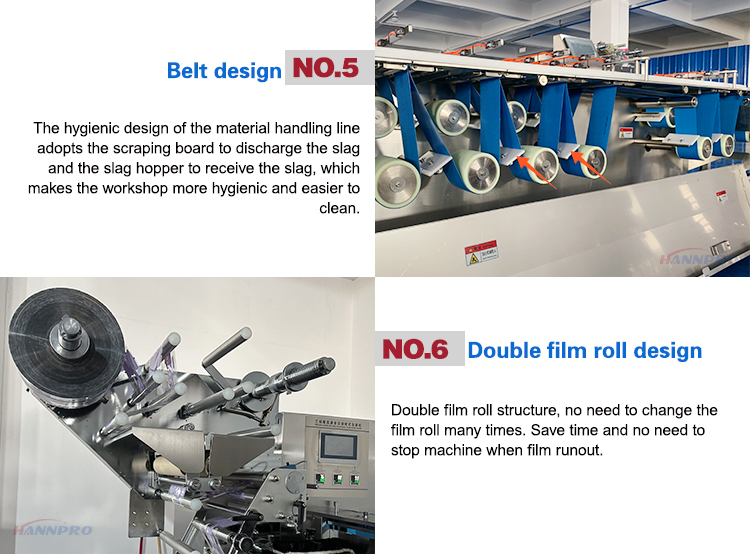

3. Packaging unit

Function: To package the sorted biscuits once (such as putting them into food-grade plastic bags, aluminum foil bags, etc.) Automatic Biscuit Packing Line.

Equipment:

Bag-making, filling and sealing machine

Bag-making module: Turns the roll film into bag shape (three-side sealing, back sealing, etc.).

Filling module: Put a certain amount of biscuits into bags Automatic Biscuit Packing Line.

Sealing module: The bag opening is sealed through heat sealing or cold sealing technology. Some devices support date printing Biscuit Packaging Line.

Bag-in-bag packaging machine: Suitable for pre-prepared bag packaging, with a higher degree of automation and faster speed Automatic Biscuit Packing Line.

4. Auxiliary units

Metal detector: It detects whether the packaged products contain metal foreign objects to ensure food safety.

Weight re-inspection scale: Conduct random weight checks on packaged finished products to remove those that do not meet weight standards Automatic Biscuit Packing Line.

Shaping conveyor: It arranges and organizes the packaged products to facilitate subsequent secondary packaging (such as boxing).

Ii. Work Process

The typical working process of the automatic sorting and one-time packaging line for biscuits is as follows:

Cookie input: After baking, the cookies are cooled down through the cooling line and then conveyed to the sorting unit by the conveyor Automatic Biscuit Packing Line.

Visual inspection and sorting

The visual system conducts real-time detection of biscuits and marks non-conforming products (such as broken or deformed ones).

The sorting device removes the non-conforming products, and the qualified products enter the counting stage Automatic Biscuit Packing Line.

Counting and grouping: The number of biscuits is counted through photoelectric sensors or weighing modules, and they are divided into several groups according to the set specifications (such as 100 grams per pack).

Packaging operation:

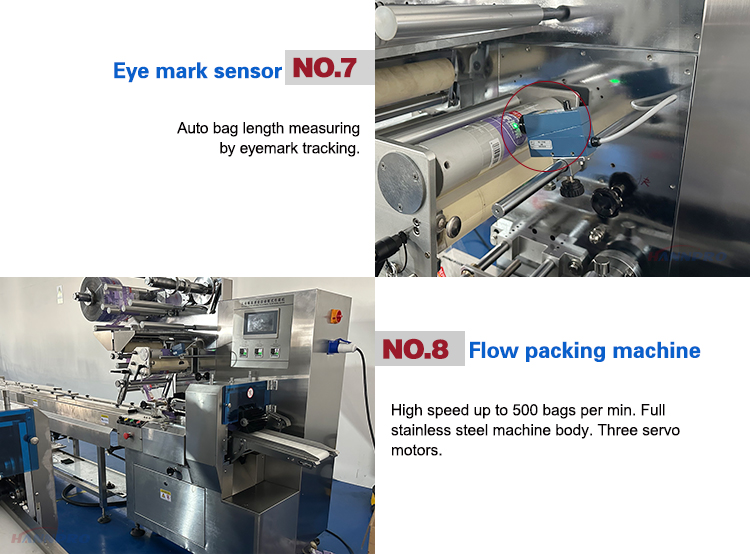

The bag-making, filling and sealing machine automatically completes bag-making, material loading, sealing and date printing Automatic Biscuit Packing Line.

The bag-feeding packaging machine directly grabs the pre-prepared bags to complete the filling and sealing.

Quality inspection: The packaged products are screened by a metal detector and a weight recheck scale to ensure they meet the quality standards Automatic Biscuit Packing Line.

Finished product output: Qualified products are conveyed out by conveyors and enter the secondary packaging process (such as boxing and palletizing).

Iii. Core Technologies

Visual inspection technology

Principle: By using a high-resolution camera to capture images of cookies and comparing them with standard templates through AI algorithms (such as image recognition and defect detection), defects can be quickly identified Automatic Biscuit Packing Line.

Advantages: High detection accuracy (up to 0.1mm level), fast speed (processing hundreds of cookies per second), and reduced manual missed detections.

2. High-speed sorting technology

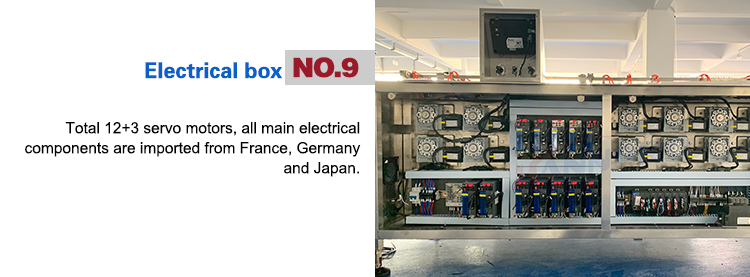

Mechanical hand sorting: The mechanical arm is driven by a servo motor, with a positioning accuracy of ±0.5mm and a sorting speed of up to 300 times per minute Automatic Biscuit Packing Line.

Air-blowing sorting: The airflow is controlled by an electromagnetic valve, with a response time of less than 50ms. It is suitable for the rapid removal of light and small biscuits.

3. Intelligent packaging technology

Servo motor control: Bag-making, filling, sealing and other actions are driven by the servo system, with precise positioning. The packaging speed can reach 60-120 bags per minute Automatic Biscuit Packing Line.

Adaptive adjustment: The size of the cookies is monitored in real time by sensors, and the packaging bag specifications are automatically adjusted to be compatible with multiple product models.