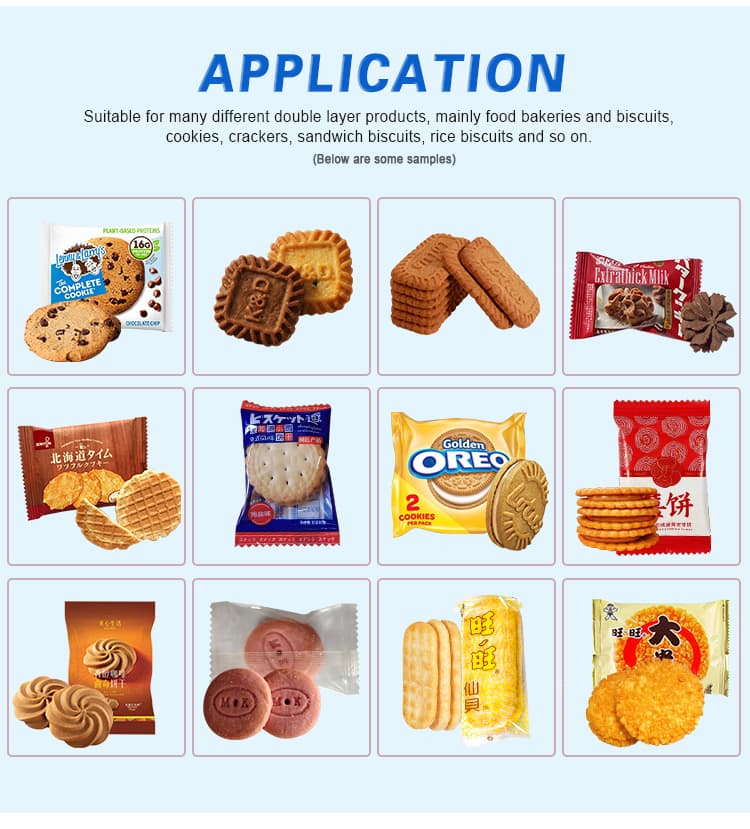

The stacked biscuit packaging machine is a device used for the automatic packaging of stacked biscuits and is widely applied in the food processing industry. The following is its related introduction:

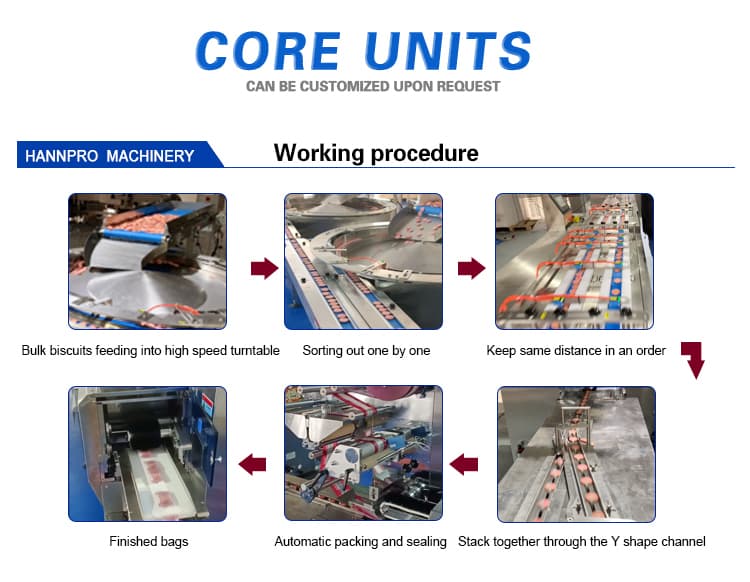

Working principle

Usually, a conveyor belt is used to transport the stacked cookies to the packaging area, and then the cookies are accurately placed on the packaging materials through mechanical arms or other automated devices biscuit packaging machine.

Next, the biscuit packaging machine packaging materials will undergo operations such as folding and sealing according to the preset program to complete the packaging of the cookies biscuit wrapping machine. Some advanced machines can also shape the appearance of packaging and conduct quality inspections to ensure that the packaged biscuits have a neat appearance and are well sealed.

Structural composition

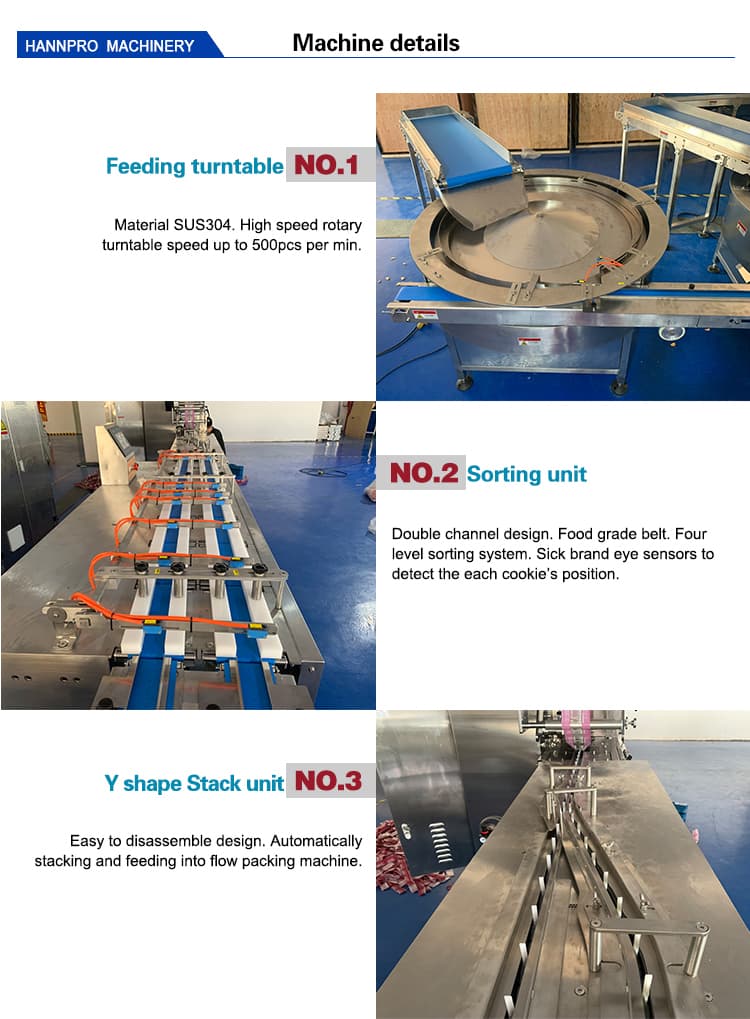

Feeding system: It mainly includes components such as conveyor belts and feeding hoppers. Biscuit wrapping machine function is to smoothly and orderly transport the stacked biscuits to the packaging position, ensuring that the biscuits can accurately enter the packaging process.

Packaging system: It is the core part, composed of packaging material supply devices, sealing devices, cutting devices, etc. The packaging material supply device is responsible for providing the materials required for packaging, such as plastic films, paper boxes, etc. The sealing device seals the packaging materials by means of heating, pressurizing, etc., to ensure the sealing property of the biscuits. The cutting device cuts the packaging materials into the appropriate shapes according to the set dimensions biscuit packaging machine.

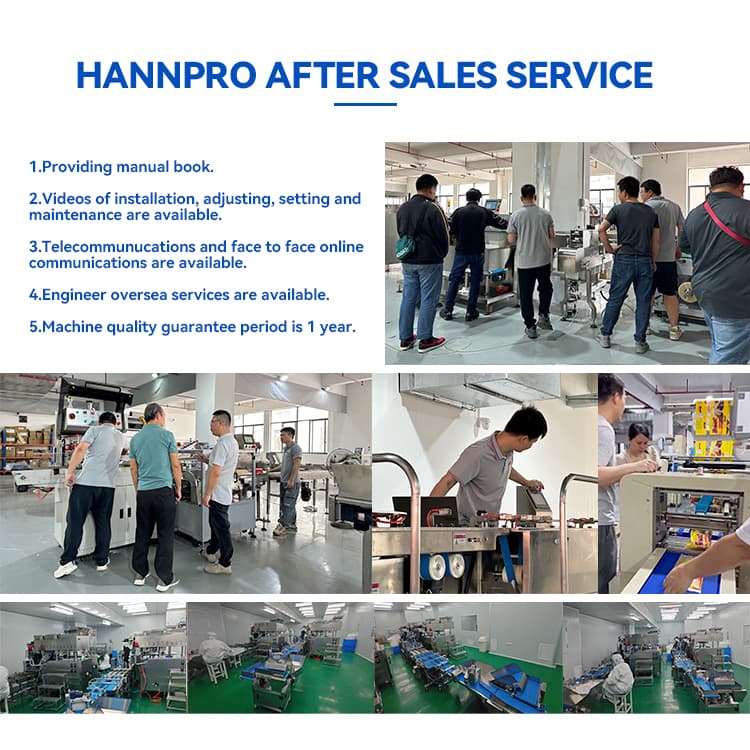

Control system: Generally composed of PLC (Programmable Logic Controller) and human-machine interface. Operators can set packaging parameters such as packaging speed, packaging size, and sealing temperature through the human-machine interface biscuit wrapping machine. The PLC then controls the operation of each component according to the preset program, achieving the automatic control of the entire packaging process multi pack biscuit packing machine.

Detection system: including photoelectric sensors, weight detection devices, etc. Photoelectric sensors are used to detect the position and quantity of biscuits to ensure the accuracy of packaging. The weight detection device conducts weight checks on the packaged biscuits, eliminating those that do not meet the weight standards to ensure the stability of product quality automatic biscuit packing machine.

Performance characteristics

High efficiency: It can achieve high-speed packaging, significantly enhancing production efficiency. For instance, some large stacked biscuit automatic packaging machines can package thousands of biscuits per hour, with a significant improvement in efficiency compared to manual packaging.

Accuracy: Through precise control systems and sensors, cookies can be accurately packaged, reducing packaging errors biscuit wrapping machine. For instance, in terms of the positioning of biscuits and the cutting of packaging materials, it is possible to ensure that the dimensional accuracy is within a very small range.

Stability: By using high-quality components and advanced manufacturing processes, the equipment operates stably and reliably, reducing downtime due to faults biscuit packaging machine. Under normal circumstances, a well-maintained automatic packaging machine for stacked biscuits can operate continuously for a relatively long time, ensuring the stable operation of the production line biscuit packaging machine.

Flexibility: It can be adjusted and set according to different biscuit specifications, packaging materials and packaging requirements to meet the packaging needs of various products. For example, through simple parameter Settings and mold changes, it is possible to package cookies of different shapes and sizes, as well as use packaging materials of different materials biscuit packing machine.

Maintenance and upkeep

Regular cleaning: Regularly clean the surface and interior of the machine from biscuit crumbs, dust and other debris to prevent them from entering the machine and affecting the normal operation of components. In particular, the residual biscuit crumbs on the packaging system and conveyor belt should be cleaned up in time to avoid affecting the packaging quality and the service life of the conveyor belt biscuit wrapping machine.

Component inspection: Regularly check the wear of the conveyor belt and make timely adjustments or replacements. Check the wear of the sealing components, cutting tools and other vulnerable parts of the packaging system biscuit packaging machine. If there is any wear, replace them in time to ensure the packaging quality. At the same time, check whether the connecting bolts of each component are loose. If any are loose, tighten them in time to prevent malfunctions caused by loose components biscuit packaging machine.

Lubrication and maintenance: In accordance with the requirements of the equipment manual, regularly lubricate all lubrication points of the machine, use appropriate lubricating oil or grease, ensure that the moving parts of the machine can be well lubricated, reduce wear, lower energy consumption, and extend the service life of the machine.

Electrical system maintenance: Regularly check whether the wiring connections of the electrical system are firm and whether there are any potential safety hazards such as leakage or short circuit biscuit wrapping machine. Clean the dust inside the electrical control cabinet, check the working condition of the electrical components. If any abnormality is found, repair or replace them in time biscuit wrapping machine. At the same time, it is necessary to ensure that the electrical system is well grounded to guarantee the safety of operators and equipment.