The All-in-one VFFS Machine, a vertical forming, filling and sealing machine, is a common type of automated packaging equipment, mainly used for packaging materials such as powder, granules or liquids during continuous production processes vertical form fill seal machine.

This kind of machine can automatically complete a series of operations such as bag making, metering, filling and sealing, which greatly improves the production efficiency and packaging quality vertical packaging machine.

The multi-in-one VFFS vertical packaging machine is a vertical forming, filling and sealing packaging equipment integrating multiple functions, and is widely used in the food, pharmaceutical, daily chemical and other industries vffs machine. The following is a detailed introduction about it:

Functional characteristics

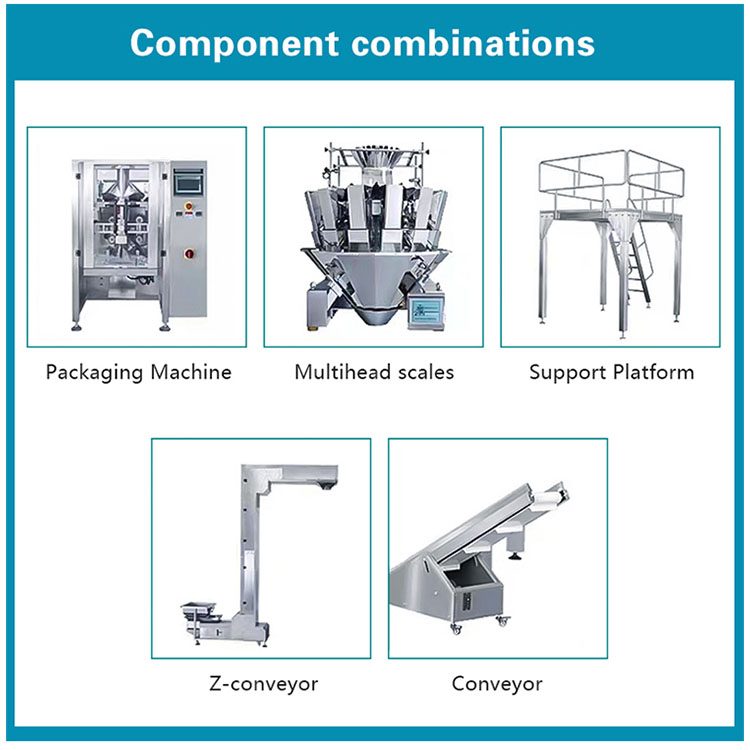

Integration of multiple functions: It can integrate functions such as automatic coding, weighing, filling, bagging, sealing and cutting, and counting, achieving the automation of the packaging process, improving production efficiency, and reducing labor costs vertical packaging machine.

High-precision measurement: Equipped with high-precision measurement devices, such as screw packing or dump packing, and independently adjustable measuring cups, etc.form fill seal machine, it ensures that precise measurement and filling can be achieved for various materials, especially powders and granules with high flow difficulty, even during high-speed operation, guaranteeing the weight accuracy of the products vertical packaging machine.

Multiple bag types to choose from: By changing different molds or forming mechanisms, various bag types can be packaged, such as pillow bags, round-bottom vertical zipper bags, square-bottom bags, and pin bags, to meet the packaging requirements of different products vertical packaging machine.

The packaging materials have strong adaptability: They can adapt to various packaging materials, such as plastic films, composite films, paper-plastic composite materials, etc. They can be selected according to the characteristics of the product and packaging requirements. At the same time, they also support sustainable packaging materials, which is in line with the trend of environmental protection vertical packaging machine.

Intelligent control system: It adopts imported PLC and human-machine interface control system, with full Chinese and English touch screen operation vffs. The working status and operation instructions are clear and straightforward, facilitating parameter setting, equipment debugging and monitoring by operators. It also has an automatic fault alarm display function, which can promptly prompt the cause of the fault and help quickly eliminate the fault vertical packaging machine.

High-precision film pulling and positioning: Equipped with a high-precision servo film pulling system, the film pulling is smooth. It is also equipped with a color standard photoelectric and encoder automatic positioning and tracking system, which can precisely control the bag length and the conveying position of the film material, ensuring the dimensional accuracy of the packaging and the accuracy of pattern printing vertical packaging machine.

Working principle

The packaging materials are installed on the unwinding device of the machine. Through the guide rollers and tension control system, the flat film is conveyed to the forming machine. Under the action of the forming machine, the flat film is folded into a cylindrical shape, forming the initial form of the packaging bag.

After the materials are precisely measured by the metering device, they fall from the hopper into the formed packaging bag cylinder vertical packaging machine.

Under the action of the traction device, the packaging bag moves downward. Meanwhile, the longitudinal sealing device heats and seals the longitudinal seams of the packaging bag to form a complete bag cylinder.

When the packaging bag reaches the transverse sealing device, the device performs transverse sealing and cutting on the packaging bag, completing the forming, filling and sealing process of a packaging bag.

Application field

Food industry: It can be used for packaging various foods, such as milk powder, soybean meal, protein powder, coffee powder, wheat powder, tea powder, baking soda powder and other powdered materials, as well as potato chips, nuts, candies and other granular or block foods. It can also be used for packaging fresh fruits and vegetables and frozen foods vertical packaging machine.

Pharmaceutical industry: It is suitable for the packaging of drugs, such as single-dose or multi-dose packaging of drug powders, granules, capsules, etc., which can ensure the sealing and accuracy of drug packaging and meet GMP requirements.

Daily chemical industry: It can be used for packaging daily chemical products, such as laundry powder, liquid laundry detergent, dishwashing liquid, toothpaste, cosmetics, etc., to meet the packaging needs of different products and enhance the market competitiveness of the products.

Other industries: It is also widely used in the pesticide, veterinary drug, chemical raw material and other industries, and can package powdery, granular or liquid materials, achieving product measurement, filling and sealing vertical packaging machine.