Automatic bottle cartoning machine

The automatic bottle packing machine is an automated device used to automatically organize, arrange and load bottles (such as beverage bottles, glass bottles, plastic bottles, etc.) into cartons or plastic boxes.

It is widely used in the food, beverage, daily chemical, pharmaceutical and other industries box erector machine. Its core function is to replace manual packing, improve production efficiency, reduce labor intensity, and at the same time ensure the neatness and stability of packing box erector.

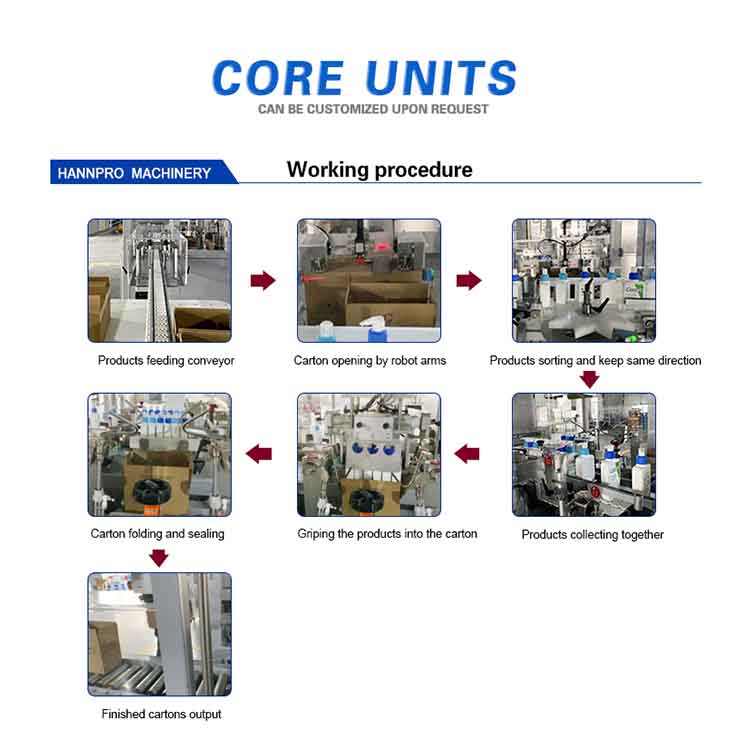

I. Main Structure and Working Principle

Conveying system

It includes the feeding conveyor belt and the discharging conveyor belt, which are used for conveying bottles and boxes.

Bottles are conveyed to the inlet of the case packing machine through the front-end production line (such as filling machine, labeling machine), and the boxes are placed at the designated positions by the case opening machine or manually box erector.

Organize and arrange the structure

Bottle separation device: It separates the continuously conveyed bottles into individual or group arrangements to facilitate subsequent boxing box erector.

Arrange the mold: According to the box specifications (such as the number of bottles per row/column), the bottles are arranged into the predetermined formation (such as matrix type) through mechanical baffles case erector and sealer, bottle push rods, etc box erector.

Packing actuator

Gripper/suction cup device: Use mechanical grippers or vacuum suction cups to pick up the arranged bottles and precisely place them into the empty box below box erector.

Servo motor drive: Ensures the accuracy and stability of grasping, moving and placing actions, and is adaptable to different bottle types (such as round bottles, square bottles) and box types box erector.

Box positioning and fixation system

The boxes are positioned by using photoelectric sensors or mechanical baffles to prevent them from shifting during loading box erector.

Some of the equipment is equipped with a box pressing device to ensure that the bottom of the box is flat after the bottles are filled box erector.

Control system

It is controlled by PLC (Programmable Logic Controller) or industrial computer case erector machine, and supports human-machine interface (HMI) operation. It can set packing parameters (such as the number of bottles and arrangement method), and monitor the operation status of the equipment in real time box erector.

Ii. Applicable Scenarios and Advantages

Applicable scenarios

Industry: Beverages (mineral water, carbonated drinks, beer), condiments (soy sauce, vinegar), daily chemicals (shampoo, laundry detergent), medicine (oral liquid, reagent bottles), etc box erector.

Bottle types: Glass bottles, plastic bottles, metal cans, with specifications ranging from small bottles (100ml) to large bottles (2L) box erector.

Core advantage

High efficiency and stability: The packing speed can reach 10 to 50 boxes per minute (depending on the bottle type and box size), far exceeding manual efficiency Robotic Case Erector, and the arrangement is neat with a low breakage rate box erector.

Flexible production: By changing molds and adjusting parameters, different bottle and box types can be quickly switched to meet the demands of multi-variety and small-batch production box erector.

Cost reduction: Reduce labor input, lower labor intensity, and is especially suitable for repetitive and labor-intensive packaging processes box erector.

Hygiene and safety: Fully enclosed or semi-enclosed structure, reducing manual contact, and meeting the hygiene standards of the food and pharmaceutical industries box erector.

Iii. Key Points for Classification and Selection

Classify by packing method

Grid-type case packing machine: It uses grippers to pick up bottles one by one or in groups and place them in boxes. It is suitable for all kinds of bottle types and is the most widely used box erector.

Bottle-pushing type case packing machine: It uses push plates to push the arranged bottles into the box. It is suitable for lightweight bottle types (such as plastic bottles) and has a relatively low cost box erector.

Drop-out case packing machine: Bottles fall into the box from a height along the guide rail. It is suitable for impact-resistant bottle types (such as glass bottles), with a relatively high speed but lower precision box erector.

Selection reference factors

Bottle type and box type: They need to match the bottle size (diameter, height), weight and box specification (length × width × height).

Capacity requirement: Select the packing efficiency of the equipment (boxes per minute) based on the production line speed box erector.

Degree of automation: Whether it needs to be linked with front-end equipment (such as filling machines, labeling machines) to achieve full-process automation box erector.

Budget and maintenance costs: Grasping devices have high precision but are relatively expensive, while bottle-pushing or drop-out devices have lower costs but limited application ranges box erector.

Iv. Maintenance and Common Faults

Daily maintenance

Clean the debris and stains on the conveyor belt to avoid affecting the positioning of the bottles box erector.

Check the wear of the gripper/suction cup and replace the vulnerable parts (such as sealing rings and vacuum pipelines) in time.

Lubricate mechanical transmission components (such as chains and guide rails) to ensure smooth operation box erector.

Common Faults and Solutions

Bottle misalignment: Adjust the spacing of the bottle separation device or check if the photoelectric sensor is malfunctioning box erector.

If the bottle is damaged during packing: Reduce the speed of the gripper movement or replace it with a softer grasping material (such as a silicone suction cup).

Inaccurate box positioning: Calibrate the position of the mechanical baffle or clean the sensor sensing surface box erector.

V. Development Trends

Intelligence and digitalization: Integrating Internet of Things (IoT) technology, it monitors the status of equipment in real time through sensors, supporting remote fault diagnosis and production data statistics.

Green and energy-saving: Servo motors are adopted to replace traditional pneumatic components, reducing energy consumption. Optimize the mechanical structure to reduce noise and vibration box erector.

High speed and flexibility: Develop multi-station synchronous packaging technology to enhance production capacity; It adopts a modular design to achieve rapid type change (such as completing mold replacement within 10 minutes).