The 3-in-1 Coffee Powder Packaging Machine is an automated coffee powder packaging and boxing line powder stick pack machine. It rapidly packages small strips of coffee powder in multiple columns and quickly performs counting, sorting and boxing multi lane stick pack machine.

The three-in-one coffee powder packaging line is an automated packaging solution specially designed for the production of three-in-one coffee (that is, coffee beverages mixed with coffee powder, sugar and creamer). This packaging line can efficiently and precisely mix the three components in proportion and complete a series of operations from measurement, bag making, filling, sealing to cutting, powder stick pack machine making it suitable for large-scale production.

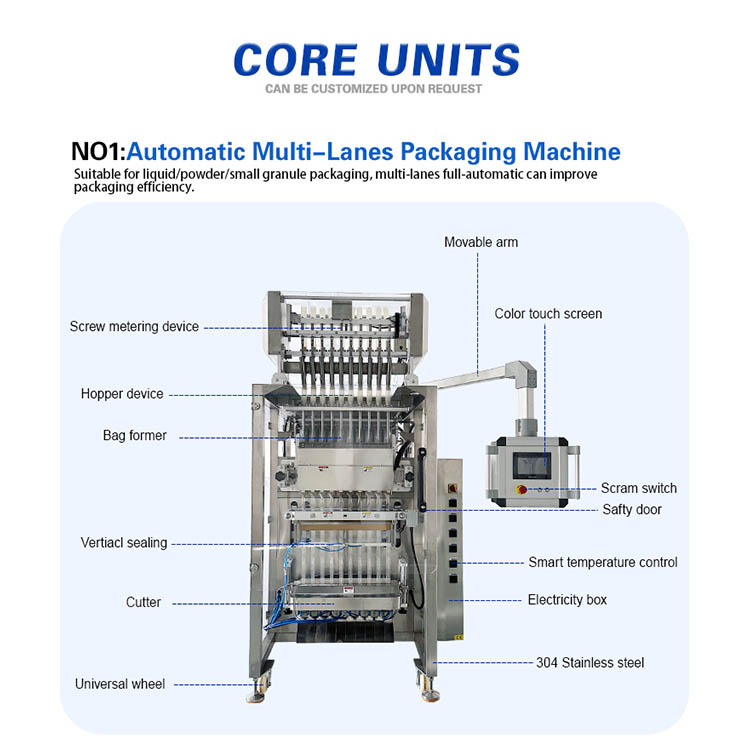

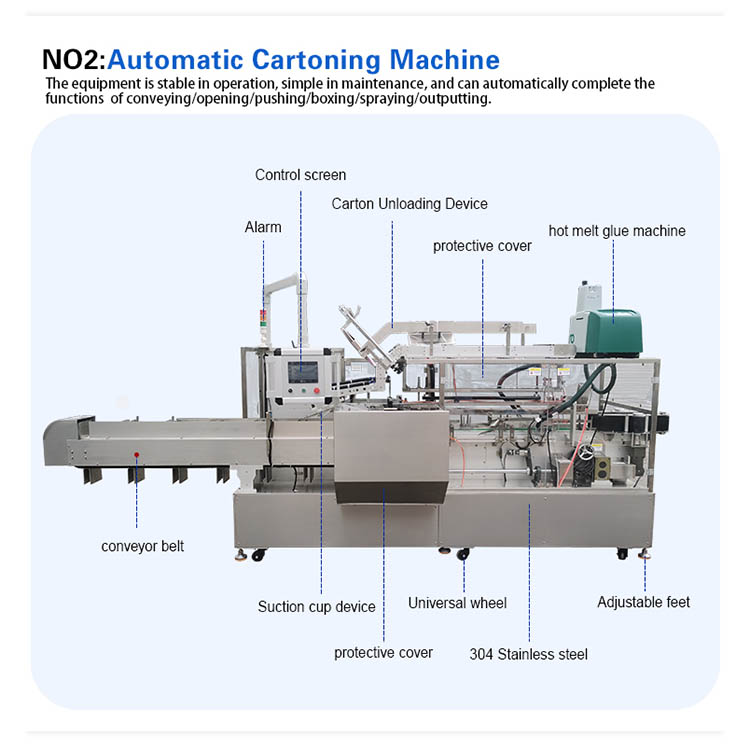

Main components and characteristics

Raw material supply system: Ensure that raw materials such as coffee powder, coffee powder filling machine powdered sugar and creamer can be accurately supplied in accordance with the preset proportion. It is usually equipped with high-precision weighing or volumetric metering devices to ensure that the proportion of ingredients in each serving of the three-in-one coffee is consistent powder stick pack machine.

Mixing system: Evenly blend different ingredients to ensure that the taste of each packet of three-in-one coffee is consistent. Efficient mixing technology is crucial for maintaining product quality.

Automatic packaging machine

Multi-column design: Supports simultaneous packaging of multiple channels, coffee stick packing machine enhancing production efficiency.

Bag-making and filling: Produce suitable packaging bags as required and fill them with the mixed coffee powder powder stick pack machine.

Sealing and cutting: The packaging bags are sealed by heat sealing or other methods and then cut into individual small packages.

Intelligent control system: Modern three-in-one coffee powder packaging lines are usually equipped with PLC control panels or touch screen interfaces, which facilitate operators to set parameters, monitor the production process and adjust the equipment status. Some high-end models also support Internet connection functions to achieve remote monitoring and data management.

Cleaning and Maintenance: Considering the requirements of food hygiene and safety, the design of the packaging line should be convenient for cleaning and maintenance to reduce the risk of cross-contamination.

Customizability: According to the different needs of various customers, different packaging specifications, capacities and appearance designs can be customized powder stick pack machine.

Selection considerations

Production capacity: Determine the production capacity of the packaging line based on the projected market demand.

Product features: Considering the different physical properties of coffee powder, stick filling machine sugar and creamer, such as fluidity and adhesion, select the appropriate equipment configuration.

Budget constraints: Under the premise of meeting production demands, select the solution with the highest cost performance powder stick pack machine.

Market trends: Pay attention to changes in consumer preferences and market trends, and flexibly adjust product specifications and packaging forms.

By using the three-in-one coffee powder packaging line, producers can not only significantly enhance production efficiency and reduce labor costs, but also ensure product quality and consistency, which is conducive to improving the brand's market competitiveness.