1. Classification by packaging process

Filling machinery

It is used for quantitatively filling products (liquids, powders, granules, blocks, etc.) into packaging containers.

For example: liquid filling machines, powder packaging machines, granule packaging machines, sauce filling machines, etc.

Sealing machine

Seal the packaging containers to ensure the product's airtightness and shelf life.

For example: heat sealing machines, capping machines, pressing machines, aluminum foil sealing machines, vacuum sealing machines, etc.

Wrapping machine

Wrap the product with packaging materials such as film or paper.

For example: winding packaging machines, stretch film packaging machines, shrink packaging machines, twist wrapping machines, etc.

Labeling machine

Labels are affixed to the packaging containers to identify product information.

For example: automatic labeling machines, round bottle labeling machines, flat surface labeling machines, self-adhesive labeling machines, etc.

Strapping machinery

Use strapping bands to bind multiple products or packages together.

For example: automatic strapping machines, steel band strapping machines, plastic band strapping machines, etc.

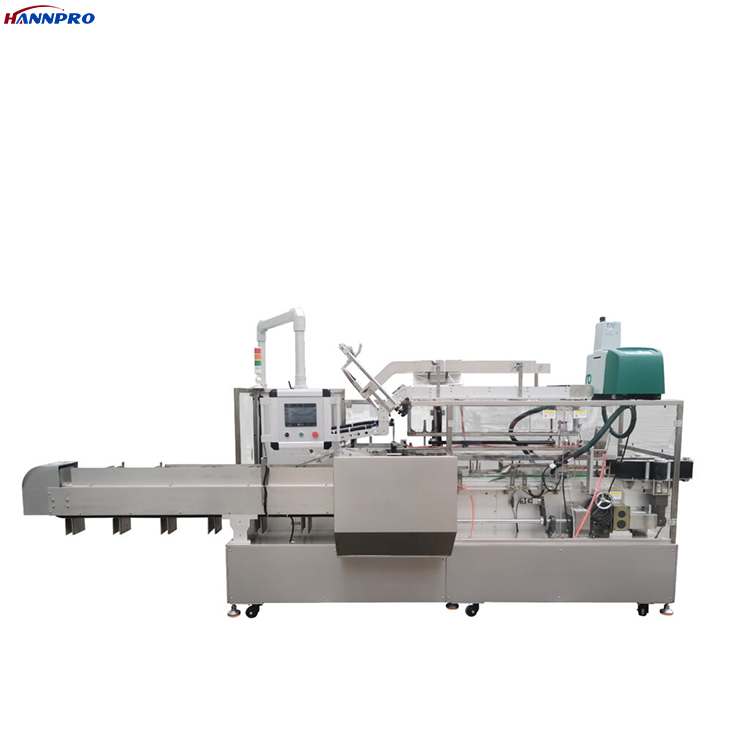

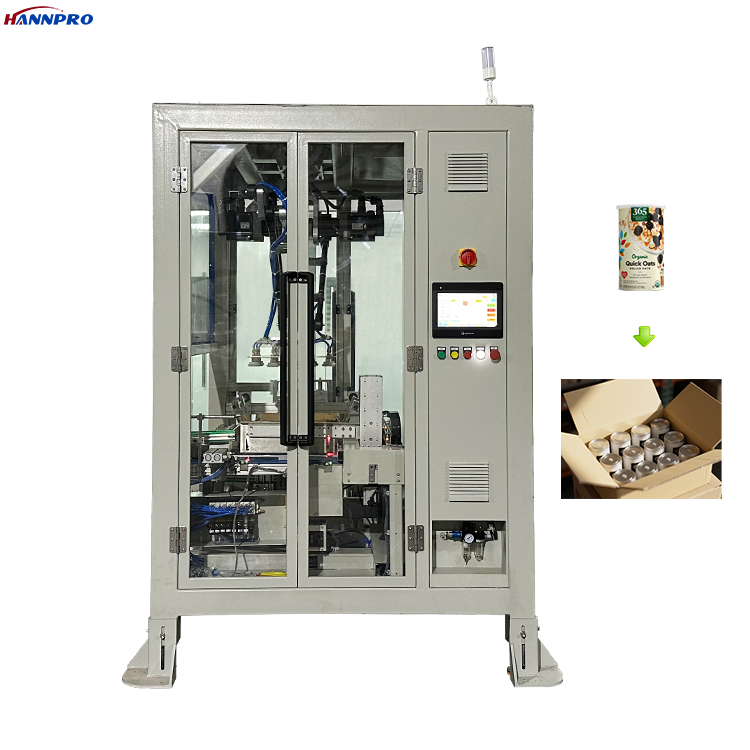

Boxing machinery

Automatically pack the products into cartons or boxes.

For example: automatic case packing machines, case opening machines, box packing machines, carton forming machines, etc.

Palletizing/unloading machinery

Stack the packaged products onto the pallets according to the rules (palletizing), or remove them from the pallets (unpalletizing).

For example: automatic palletizing machines, robot palletizing systems, etc.

Cleaning/drying machinery (mainly used for pre-treatment before packaging)

For example: bottle washing machines, dryers, etc.

2. Classification by degree of automation

Manual packaging machinery: Operation relies on manual labor and is suitable for small-batch production.

Semi-automatic packaging machinery: Some processes are automatic, while others require manual intervention.

Fully automatic packaging machinery: The entire packaging process is completed automatically, with high efficiency and suitable for large-scale production.

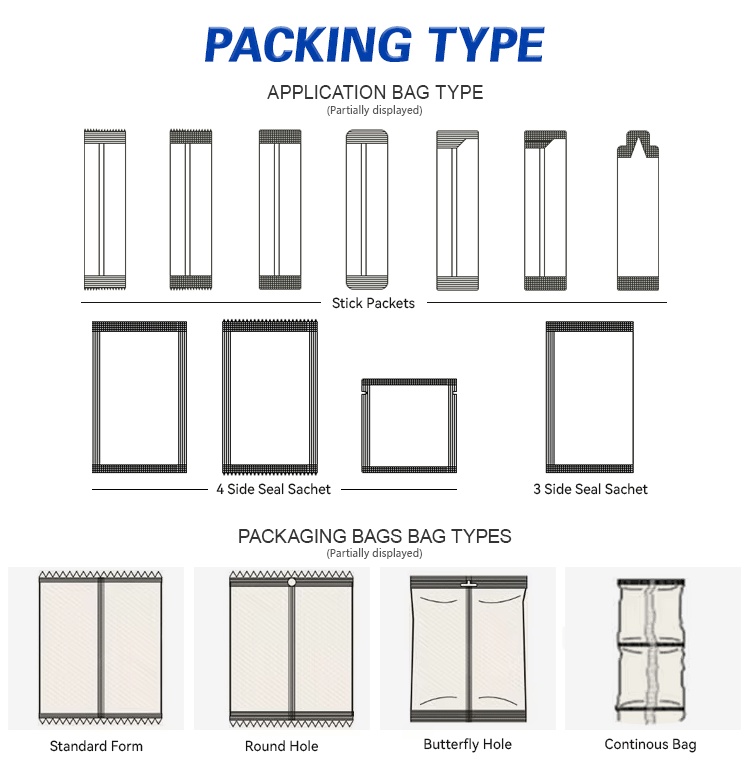

3. Classification by packaging materials

Plastic packaging machinery (such as bottle blowing machines, thermoforming machines)

Paper packaging machinery (such as paper bag machines, paper box forming machines)

Metal packaging machinery (such as can-making machines, can-sealing machines)

Glass packaging machinery (such as bottle washing machines, filling and capping integrated machines)

4. Classification based on product type adaptation

Food packaging machinery (such as vacuum packaging machines, pillow packaging machines)

Pharmaceutical packaging machinery (such as blister packaging machines, aluminum-plastic packaging machines)

Cosmetic packaging machinery (such as filling and capping integrated machines)

Industrial product packaging machinery (such as heavy-duty strapping machines, pallet packaging machines

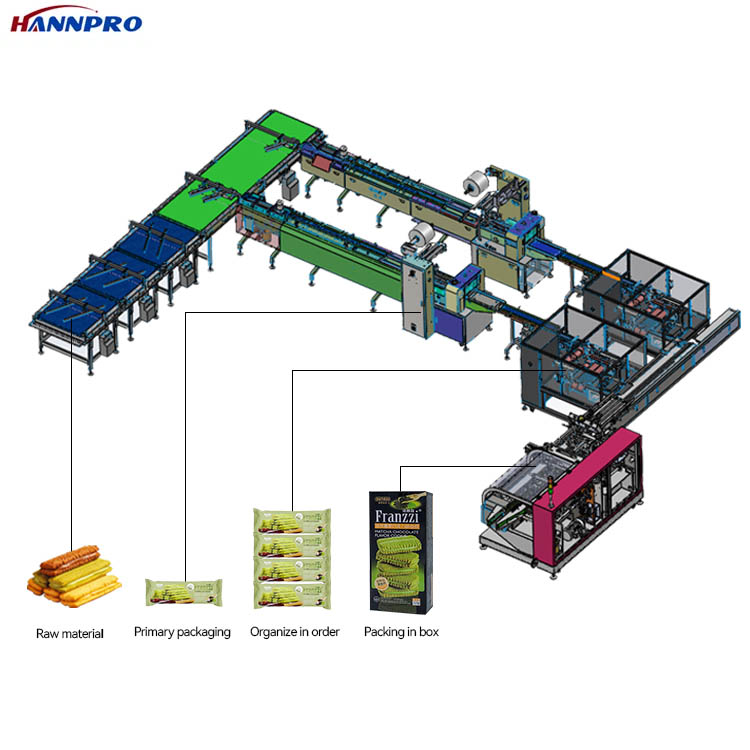

5. Combined/Multi-functional Packaging Equipment

Packaging production line: Integrated with multiple single machines, it realizes full-process automation from filling, sealing, labeling to boxing.

Multi-functional all-in-one machines: such as filling, sealing and labeling all-in-one machines, which save space and improve efficiency.