The price of a bread packaging line is not a fixed value but is determined by multiple technical, commercial and market factors bread packaging line. The following are the core elements that affect its price, classified and explained by importance

Production capacity and speed requirements

Low-speed line (<30 packs per minute) : Suitable for small workshops, price approximately ¥20,000 - ¥80,000

Medium-speed line (30-80 packs per minute) : Mainstream commercial, priced from ¥80,000 to ¥300,000

High-speed lines (>80 packets per minute, even over 150) : For large factories bread packaging line, priced from ¥300,000 to ¥1,000,000

Equipment material and hygiene standards

Ordinary carbon steel + spray painting: Low cost, but not suitable for direct contact with food, and inexpensive.

All stainless steel (304/316) : Complies with food safety standards bread packaging line, easy to clean, corrosion-resistant, and the price is 30% - 100% higher.

Whether it has passed CE, FDA, and QS certifications: This is often required by export or high-end customers and will increase design and testing costs bread packaging line.

Degree of customization

Standard model: In stock, transparent pricing, and fast delivery.

Non-standard customization: Specifically designed based on the customer's bread size bread packaging line, shape, packaging materials (such as degradable film), production line layout, etc. Payment required:

Design fee (¥5,000 - ¥50,000)

Commissioning and trial production costs

The delivery period may be extended

Market and supply chain factors

Fluctuations in raw material prices (such as stainless steel, motors, PLC controllers)

The increase in labor costs

Supply and demand relationship: During peak seasons (such as before the Mid-Autumn Festival), the delivery time of equipment is tight, and prices may increase

Policy impact: For instance bread packaging line, the enhancement of environmental protection requirements prompts manufacturers to upgrade their equipment, indirectly pushing up costs

To accurately budget the bread packaging line in a factory bread packaging line, it is necessary to systematically cover multiple dimensions such as equipment investment, supporting facilities, operating costs, and risk preparedness, and to combine the actual production capacity demands and development strategies of the enterprise. The following is a step-by-step and implementable budgeting method, applicable to new or upgraded bread packaging line projects:

I. Clarify project objectives and technical parameters (budget premise)

Before making a budget, it is necessary to first determine:

Product types: Toast, croissants, hand-torn bread, small meal buns, etc. (Shape/size affects equipment selection)

Daily/shift production target: For example, 10,000 packs per day bread packaging line, with a 3-shift system → approximately 25 to 30 packs need to be processed per minute

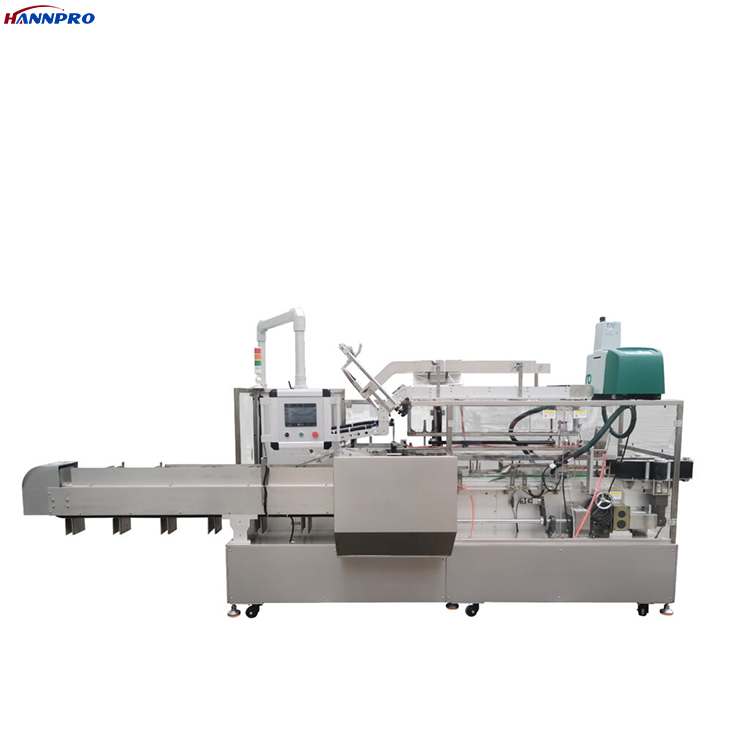

Packaging form: Pillow-type heat-sealed? Boxed? Is nitrogen filled/vacuumed?

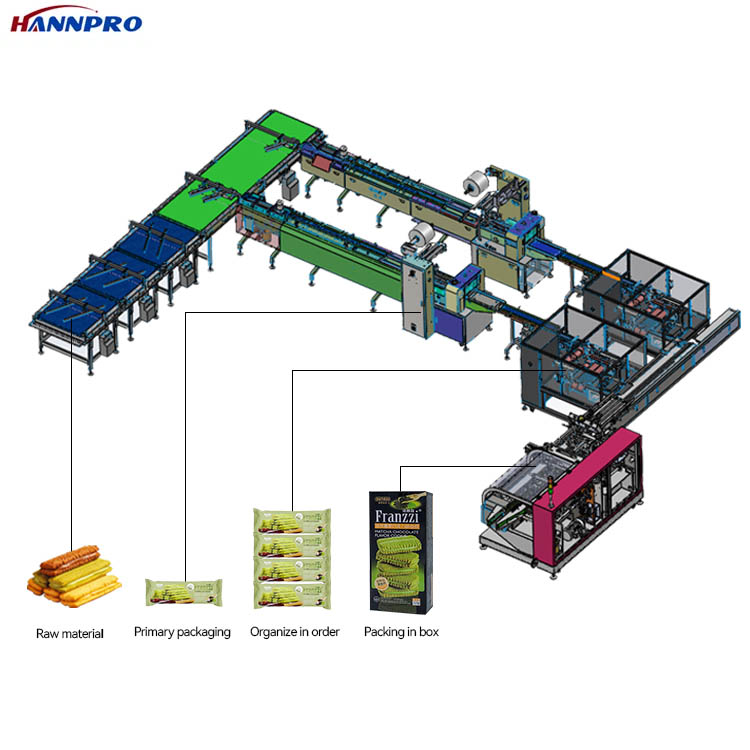

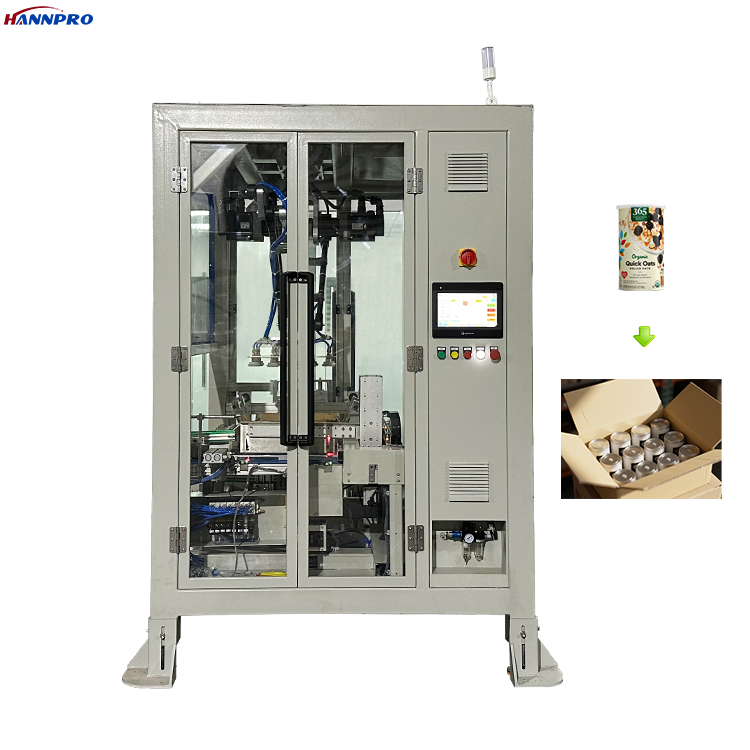

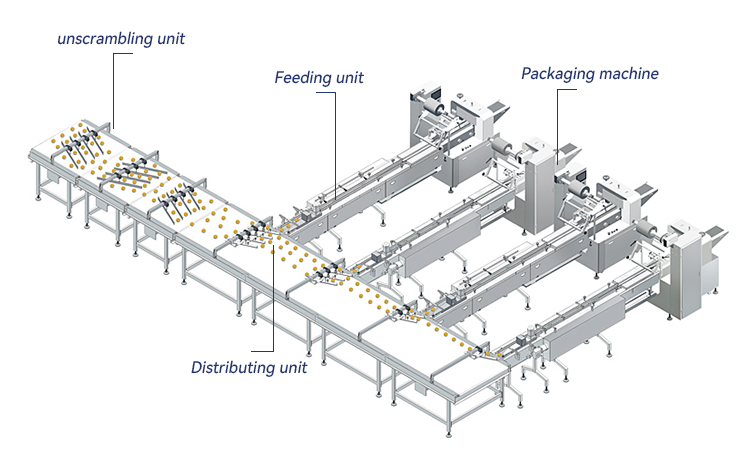

Degree of automation requirement: Fully automatic? Semi-automatic? Is it connected to the front-end cooling line or the back-end box packing and palletizing?

2. Installation and engineering costs (approximately 10% - 15%)

Equipment foundation construction (anchor bolts, shock absorption)

Electrical wiring and gas line installation (380V industrial electricity and air compressor required)

Equipment commissioning and trial operation ( bread packaging line usually included in the equipment price, but confirmation is required)

Factory renovation (such as clean area, exhaust, and lighting upgrade)

3. Personnel training and initial operating costs

Operator training (Manufacturers usually offer 1 to 3 days of free training)

First batch of packaging film/consumables procurement ( bread packaging line PE film, composite film, paper boxes, etc.)

Spare parts (blades, belts, sensors, etc.) : It is recommended to reserve 3% to 5% of the total equipment price

4. Reserve Working Capital (Key Point!)

For covering the initial stage of production:

Raw material procurement

Electricity charges and labor wages

Equipment wear and tear during the running-in period (scrap rate may reach 5% - 10%)

Market promotion and customer sample testing

5. Contingency Reserve (Not to be ignored

Basic contingency reserve: For design changes and omissions bread packaging line, it is calculated at 5% to 8% of the total investment

Contingency reserve for price increase: If the equipment delivery cycle is long (such as 3 to 6 months), consider the risk of price increases for steel, chips, etc

Ii. Key Strategies for Budget Control

Implement in phases

Phase One: First, install the core packaging line (material handling + pillow packaging)

Phase Two: Install additional modules such as inspection and packaging

Select more than three suppliers

A detailed configuration list (brand, model, warranty period) is required.

Give priority to integrators that offer "turnkey projects"

Pay attention to the total life cycle cost (TCO)

Not only should the purchase price be considered bread packaging line, but also: energy consumption, failure rate, maintenance cost and residual value

Apply for policy subsidies

Many regions offer subsidies of 10% to 30% for "intelligent manufacturing" and "green factory" projects (such as special funds for technological transformation).