stick pack sorting machine is an automated industrial system designed to handle, organize, and sort small, narrow pouches known as stick packs—typically used for single-serve portions of products like drink powders, condiments, pharmaceuticals, or personal care items.

A stick pack is a small, tube-shaped pouch, usually 5–20 cm long and sealed at both ends. It's commonly used for:

Drink mixes (e.g., coffee, juice, energy drinks)

Seasonings and sauces (e.g., soy sauce, ketchup)

Nutraceuticals and pharmaceuticals (e.g., probiotics, supplements)

Detergents or liquid soap samples

Key Functions of a Stick Pack Sorting Machine

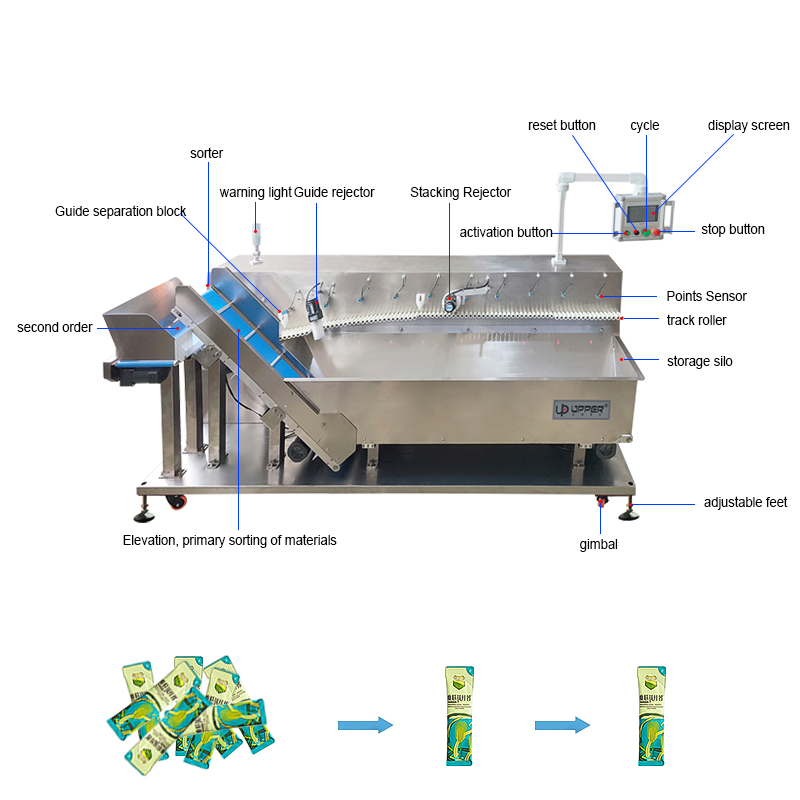

Feeding (Unscrambling & Orientation)

Takes randomly dumped or piled stick packs from a hopper.

Aligns them uniformly using vibratory feeders, conveyor systems, or rotating discs.

Inspection & Detection

Check for missing or damaged packs

Verify printing, sealing quality, or batch codes

Detect double-stacked or misaligned packs

Uses vision systems (cameras) or sensors to:

Sorting & Distribution

Product type

Flavor or variant

Customer order

Packaging stage (e.g., into multi-packs or cartons)

Directs stick packs into correct lanes or containers based on:

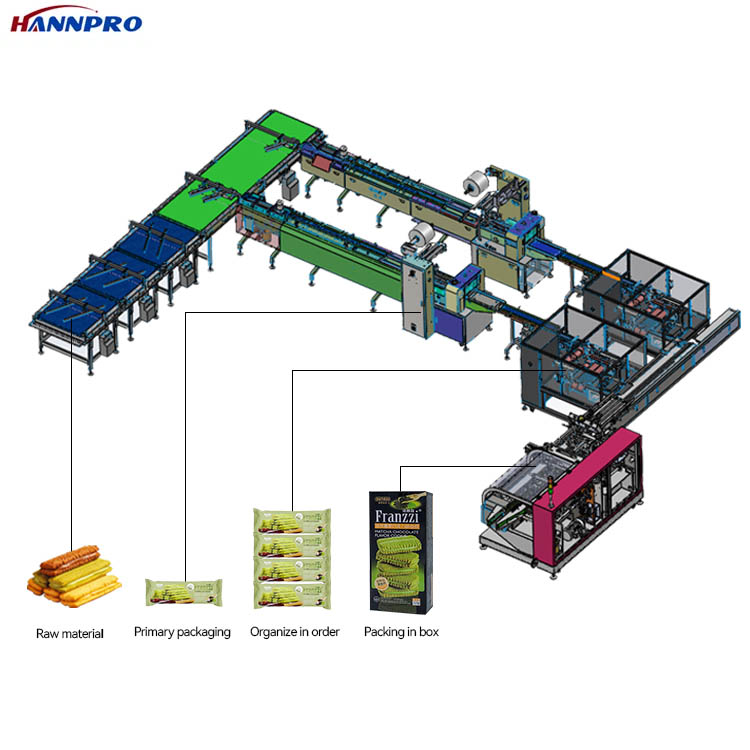

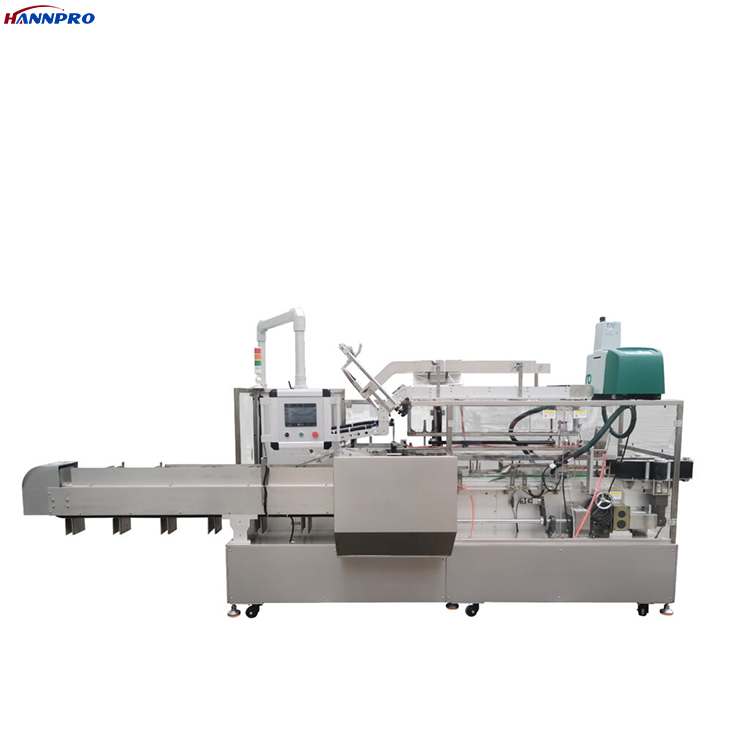

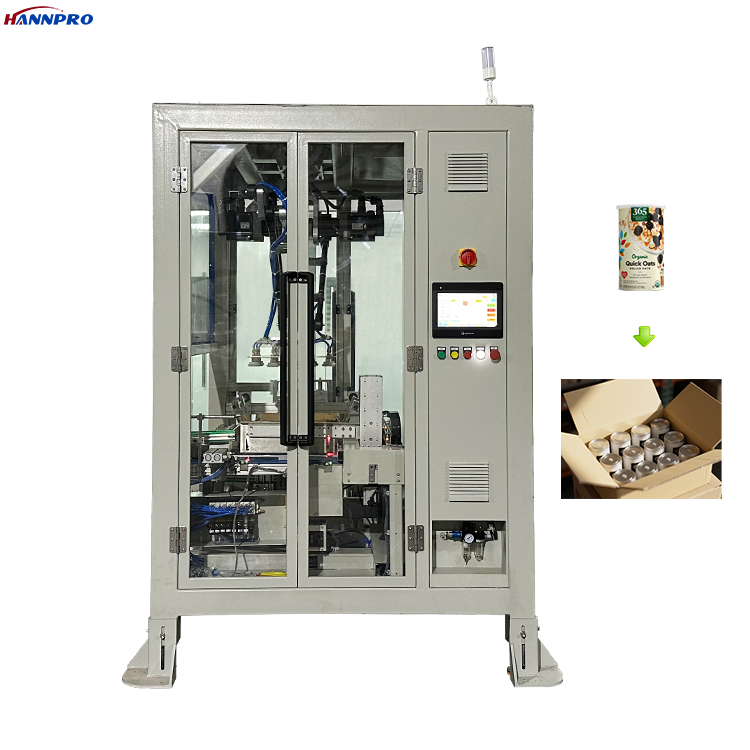

Integration with Downstream Equipment

Multi-pack wrappers (e.g., grouping 5 sticks together)

Cartoning machines

Labeling or case-packing systems

Feeds sorted stick packs into:

Common Technologies Used

Vibratory bowl feeders – Gently move and align stick packs.

Linear conveyors with guides – Transport packs in single file.

Robotic pick-and-place (with vision guidance) – For flexible, high-speed sorting.

Pneumatic or mechanical diverters – Route packs to different output channels.

Benefits

High Speed: Can process hundreds of stick packs per minute.

Consistency: Reduces human error in sorting.

Hygiene: Minimizes manual handling, important for food and pharma.

Scalability: Easily integrated into fully automated production lines.

Summary

A stick pack sorting machine automates the process of organizing and routing small stick-shaped pouches from a disordered state into a structured, efficient workflow. It ensures that the right product goes to the right packaging or shipment, improving throughput, quality control, and operational efficiency in modern manufacturing.