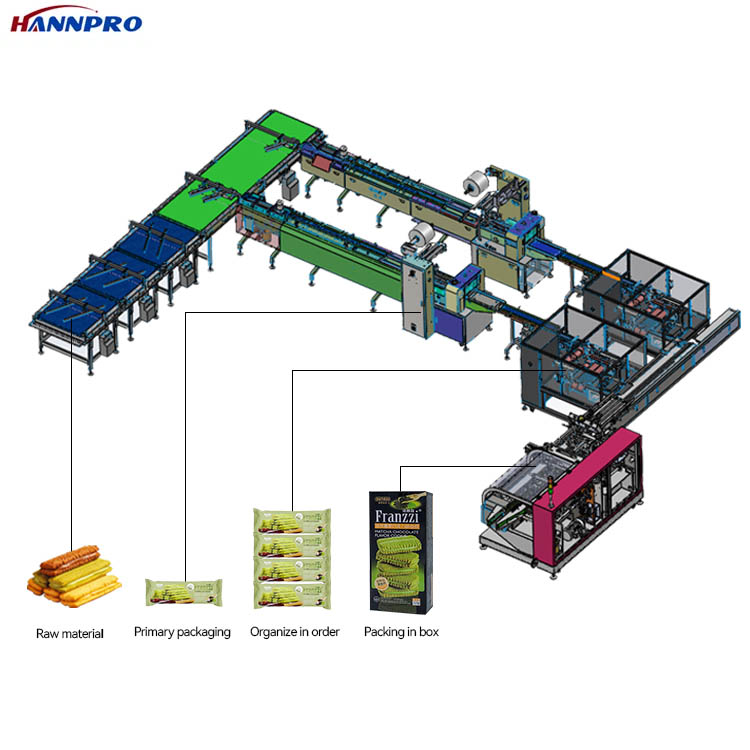

A biscuit box packing machine is an industrial machine designed to automatically package biscuits (cookies) into boxes or cartons. These machines are a crucial part of the biscuit manufacturing and packaging line, ensuring efficiency, hygiene, consistency, and speed in the packaging process.

Here’s a breakdown of what it is and how it works:

Key Functions:

Product Feeding: Biscuits are typically fed into the machine via a conveyor belt after baking and cooling. They may be arranged in specific patterns (e.g., stacked or side-by-side).

Counting & Grouping: The machine counts a precise number of biscuits per pack using sensors or mechanical counters.

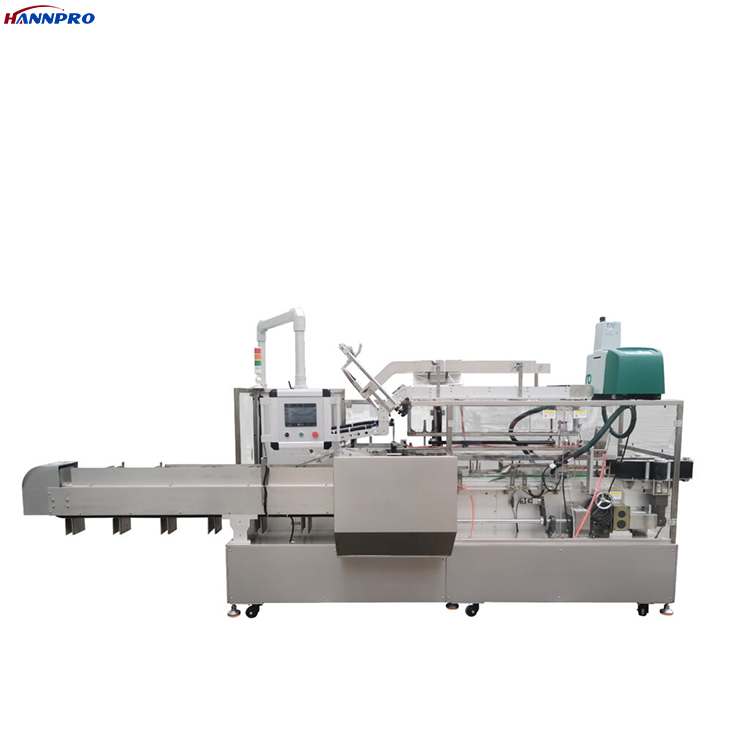

Box (Carton) Forming: In many cases, the machine forms the box from a flat cardboard blank (carton blank) using a cartoning mechanism.

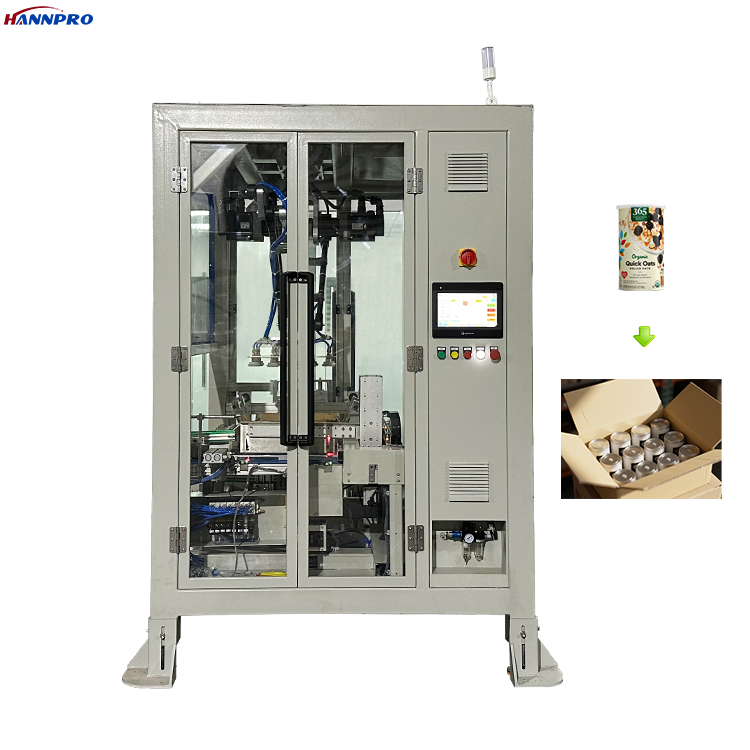

Loading: The counted biscuits are placed into the formed or pre-made box.

Sealing/Closing: The box is sealed, usually by folding and tucking the flaps, or sometimes using adhesive or tape.

Discharge: The packed box is ejected from the machine for further processing, such as labeling, date coding, or case packing.

Types of Biscuit Box Packing Machines:

Automatic Cartoners: Form, fill, and seal cartons automatically. Ideal for high-speed production.

Top-Load or End-Load Cartoners: Differ in how the biscuits are inserted into the box.

Preformed Carton Packers: Use pre-made boxes instead of forming them from blanks.

Flow Wrapping + Secondary Packing: Sometimes biscuits are first individually flow-wrapped, then grouped and packed into a box.

Key Features:

High Speed: Can pack hundreds or thousands of boxes per hour.

Adjustable: Can be adjusted for different biscuit sizes, shapes, and box dimensions.

Hygienic Design: Made from stainless steel and food-grade materials for easy cleaning.

Integrated Controls: Often use PLC (Programmable Logic Controller) systems with touch screen interfaces for easy operation and monitoring.

Benefits:

Increases packaging speed and reduces labor costs.

Ensures consistent pack quality and weight.

Minimizes product damage and contamination.

Improves overall production line efficiency.

These machines are widely used by biscuit and snack food manufacturers to meet market demands for packaged goods.