The working principle of the multi-column packaging machine

The multi-column packaging machine is an automated device, and its working principle can be summarized into the following main steps:

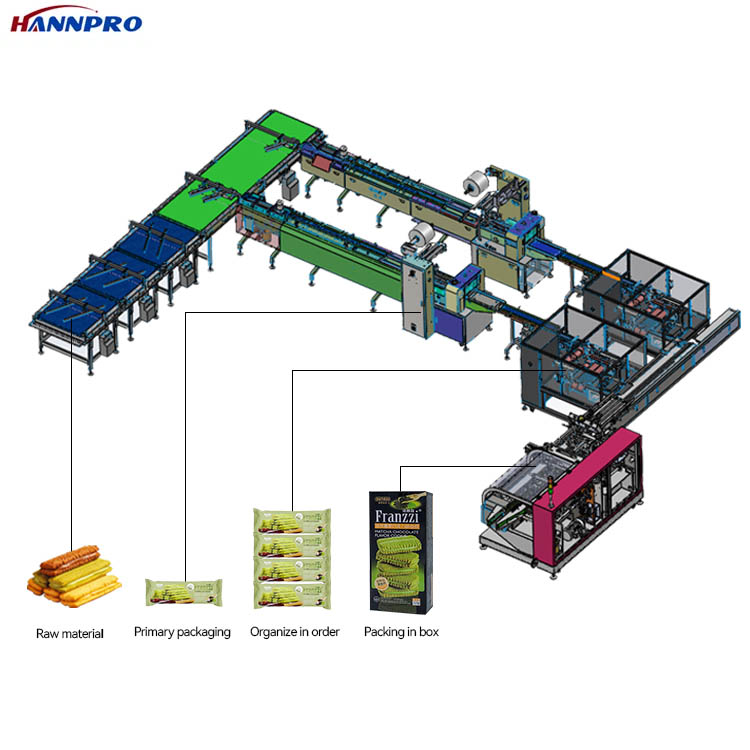

Feeding and slitting: The products first enter the multi-row packaging machine through the feeding system. Under the action of the feeding system, the products are conveyed to the feeding port of the packaging machine. Multi-column packaging machines will divide the incoming products into multiple columns according to the set packaging specifications, usually arranged column by column.

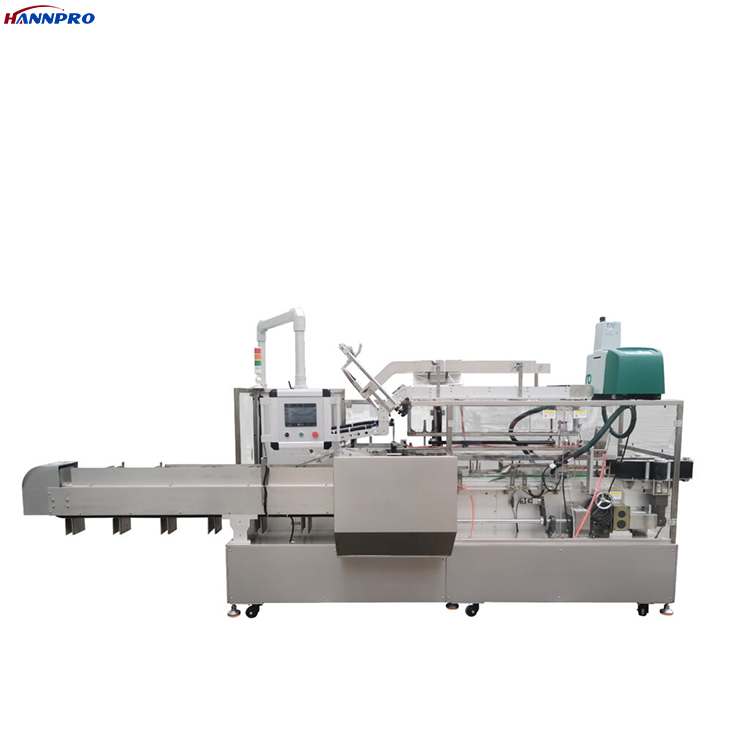

Packaging: Next, the sorted products will enter the packaging system. In the packaging system, different packaging methods are adopted according to the different packaging requirements of the products, such as bagging, bottled packaging, box packaging, etc. The multi-column packaging machine usually automatically completes the processes such as bag forming, filling, sealing and coding during the packaging process.

Control and Monitoring: The entire packaging process is intelligently managed by a control system. The control system uses PLC(Programmable Logic Controller) or other similar control devices to guide the operation of the multi-column packaging machine according to preset programs and parameters. Operators can set packaging specifications, adjust production parameters and monitor the operating status of the machine in real time through the human-machine interface.

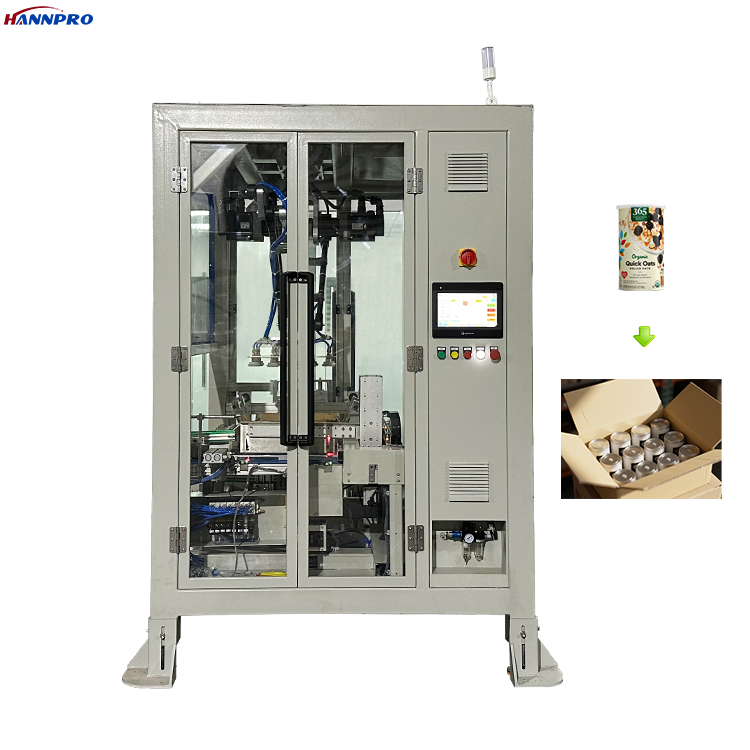

Discharge: The packaged products eventually leave the discharge port of the multi-row packaging machine and enter the next stage of the production process, such as subsequent packaging, boxing or storage, etc.

It is worth noting that the working principle of multi-column packaging machines may vary depending on different types of packaging machines and specific products. For instance, in the food industry, multi-column packaging machines may be used for packaging products such as candies, biscuits, and bottled beverages. In the pharmaceutical industry, multi-column packaging machines may be used for the packaging of medicines such as tablets and capsules. Therefore, multi-column packaging machines are usually customized and adjusted according to the characteristics of different industries and products to meet the needs of customers to the greatest extent.