The differences between horizontal cartoning machines and vertical cartoning machines

In the automated equipment system of cosmetic factories, the cartoning machine is an important piece of equipment in the packaging process horizontal cartoning machines. Among them, horizontal cartoning machines and vertical cartoning machines are widely used, and there are significant differences between the two in many aspects.

I. Structural Design and Working Principle

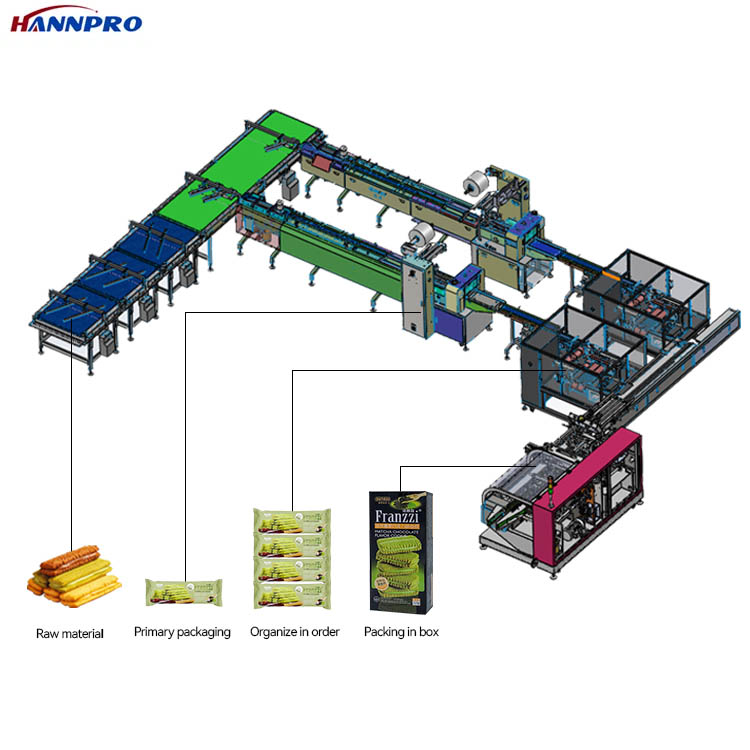

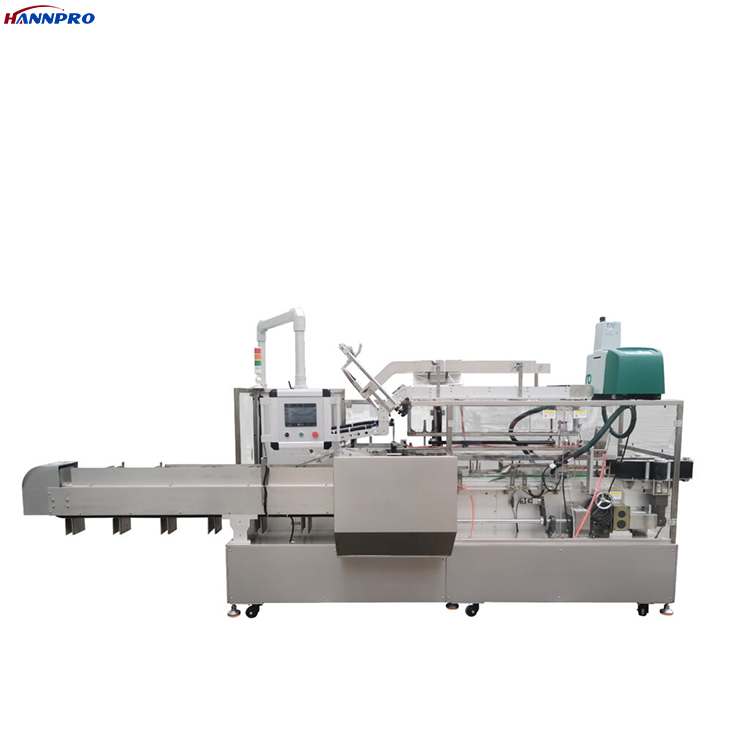

The horizontal cartoning machine is laid out horizontally as a whole. Most of the actions such as box conveying, product pushing in and box sealing are completed in the horizontal direction horizontal cartoning machines. It first sucks the paper box out of the paper box warehouse and spreads it flat on the horizontal conveyor belt horizontal cartoning machines. Then, the product moves horizontally to the box loading station through the conveyor belt or other conveying devices, and is pushed horizontally into the box by the push plate. Finally, the folding of the tongue and sealing of the box are completed. Take the cosmetic lipstick box as an example. Multiple lipsticks are first neatly arranged and then pushed horizontally into the open paper box.

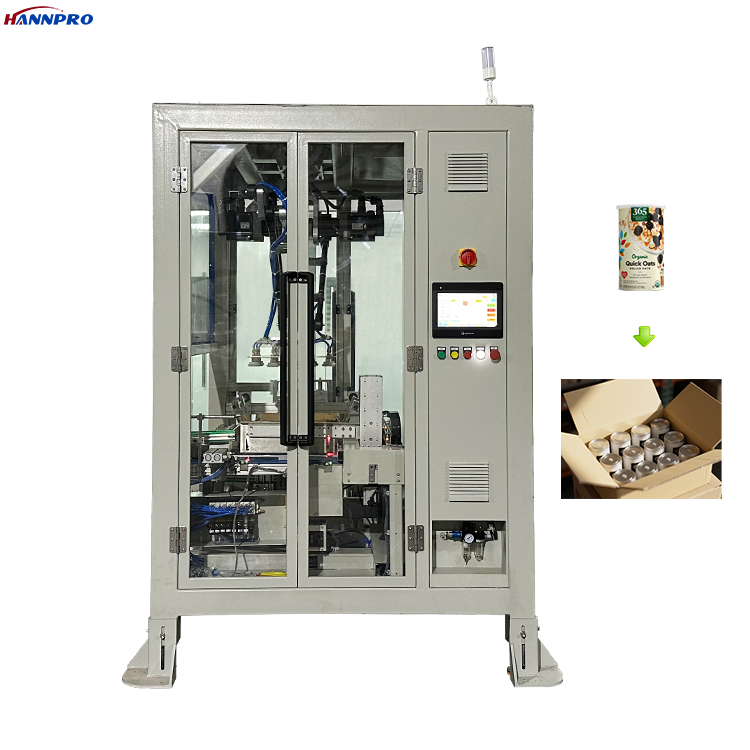

The vertical cartoning machine is structurally arranged vertically. Generally, the paper boxes are placed vertically in the paper box silo and are taken out one by one through mechanical devices and placed upright on the conveyor belt horizontal cartoning machines. The products fall vertically from above or are pushed vertically into the upright paper box, and then the edges are folded and the box is sealed. Like bottled toner, it is usually packed vertically from top to bottom into a vertical paper box horizontal cartoning machines.

Ii. Applicable Product Types

Horizontal cartoning machines are suitable for cartoning flat and regular-shaped products, such as powder compacts, eyeshadow palettes, facial masks, etc. This type of product is less likely to shift or get damaged during horizontal conveying and being pushed into the paper box, ensuring the stability and accuracy of the box packing. In addition, for some multi-piece combined product sets, the horizontal cartoning machine can also complete the cartoning by virtue of its large operating space and flexible combination methods.

Vertical cartoning machines are more suitable for cylindrical, bottle-shaped and other tall or irregularly shaped products, such as lotion bottles, spray bottles, mascara bottles, etc. As the products fall vertically or are pushed into the paper box, for taller products, it can reduce the risk of toppling or collision caused by horizontal push, and can better adapt to the irregularity of product shapes vertical cartoning machines.

Iii. Production Efficiency

Horizontal cartoning machines have obvious efficiency advantages when dealing with flat and regular products and in large production batches vertical cartoning machines. Its horizontal operation mode makes the product conveying and boxing process relatively smooth, and the movement continuity of components such as the push plate is good. For some standardized production products, high-speed boxing can be achieved. However, if the product specifications are frequently switched, due to the adjustments involving multiple aspects such as the size of the paper box and the position of the push plate, it may lead to a decrease in efficiency.

Vertical cartoning machines can also achieve high production efficiency when handling bottle-shaped and other products. However, due to the vertical placement of the paper boxes and the vertical drop of the products, the accuracy of the positioning of the paper boxes and the drop of the products during the boxing process has a significant impact on efficiency vertical cartoning machines. If the product specifications change, the adjustment of components such as the paper box warehouse and the product introduction device will be relatively complex, which may affect production efficiency to a certain extent.

Iv. Equipment Cost and Maintenance

The horizontal cartoning machine has a relatively complex structure, involving multiple horizontal transmission and operation components. Moreover, to adapt to different products and box specifications, the design and manufacturing requirements for its mechanical structure are relatively high. Therefore, the equipment procurement cost is usually high. In terms of maintenance, due to the large number of components and their scattered layout, daily inspections and troubleshooting are relatively cumbersome, and the maintenance cost is also relatively high.

The vertical cartoning machine has a relatively compact structure. Although there are certain difficulties in the design of components in the vertical direction, the overall structural complexity is lower than that of the horizontal cartoning machine, and the equipment procurement cost is relatively low. However, its vertical moving parts, such as the paper box grasping device and the product vertical feeding device, are prone to wear and tear after long-term operation vertical cartoning machines. Moreover, due to the relatively narrow space, the maintenance and replacement of some components are inconvenient, and the maintenance cost is also not to be underestimated.

V. Space Occupation

Due to its horizontal layout, the horizontal cartoning machine has a relatively long overall length, occupies a large horizontal space in the workshop, and requires a larger installation site vertical cartoning machines. When the space in the factory building is limited, it may have a certain impact on the layout of other equipment and the planning of the production process.

The vertical cartoning machine mainly operates in the vertical direction, occupies a relatively small area, and has a higher height. It is more suitable for use in workshops with limited space but high floor height, and has certain advantages in space utilization.

Vi. Shuoma Vertical Cartoning Machine: Initiating a New Era of Efficient Cartoning

Among the numerous vertical cartoning machine brands, Shuoma's vertical cartoning machine stands out with its outstanding performance of "one machine for a hundred boxes", becoming the preferred equipment for cosmetic enterprises to enhance packaging efficiency. The Shuoma vertical cartoning machine is equipped with an intelligent flexible switching system. Through the collaborative operation of high-precision servo motors and advanced PLC control systems, it can quickly adapt to the cartoning requirements of over a hundred different specifications of products such as lotion bottles and essence bottles without the need for cumbersome mold changes, truly achieving multi-purpose use with one machine.

In terms of efficiency, the high-speed operation capability of the Shuoma vertical cartoning machine is remarkable vertical cartoning machines. Its unique spiral paper box conveying and product synchronous introduction technology ensures that each small box can be filled with thousands of boxes. According to actual application data, compared with traditional vertical box filling machines, the efficiency has been increased by more than 30%. Even when dealing with long and irregular products such as mascara and lip gloss, it can accurately and quickly complete the boxing, significantly shortening the production cycle.

Not only that, but Shuoma has also made great efforts in the stability and ease of use of its equipment vertical cartoning machines. The body is made of high-strength alloy material, and the key components have undergone special wear-resistant treatment to reduce the failure rate during long-term operation. Equipped with a visual touch operation interface, operators only need to simply set product parameters, and the equipment can automatically adjust the boxing process. New employees can also quickly get started. Choosing the Shuoma vertical cartoning machine means choosing an efficient, stable and intelligent packaging solution, helping enterprises seize the initiative in the fierce market competition.