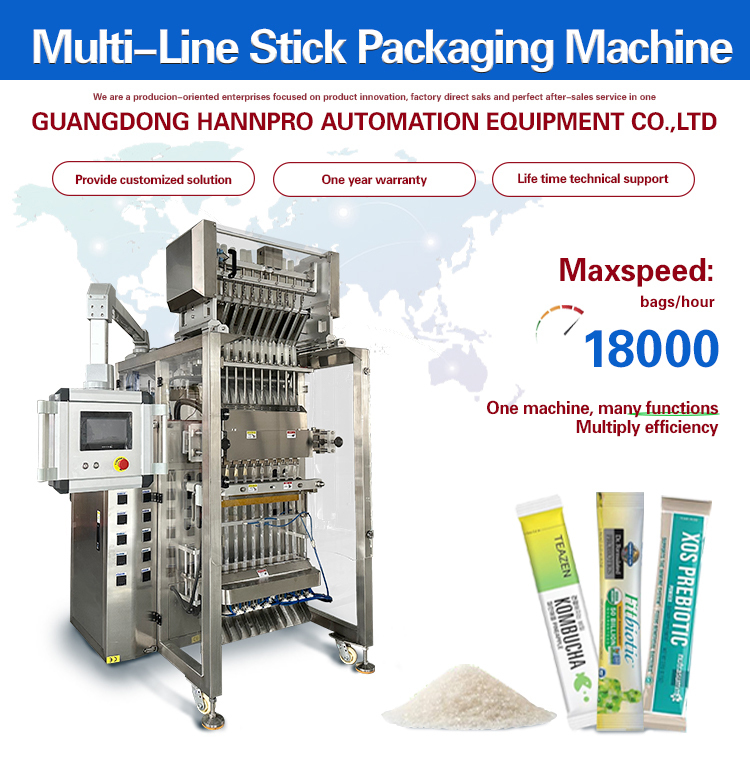

Rounded corner bar packaging multi-row packaging machine

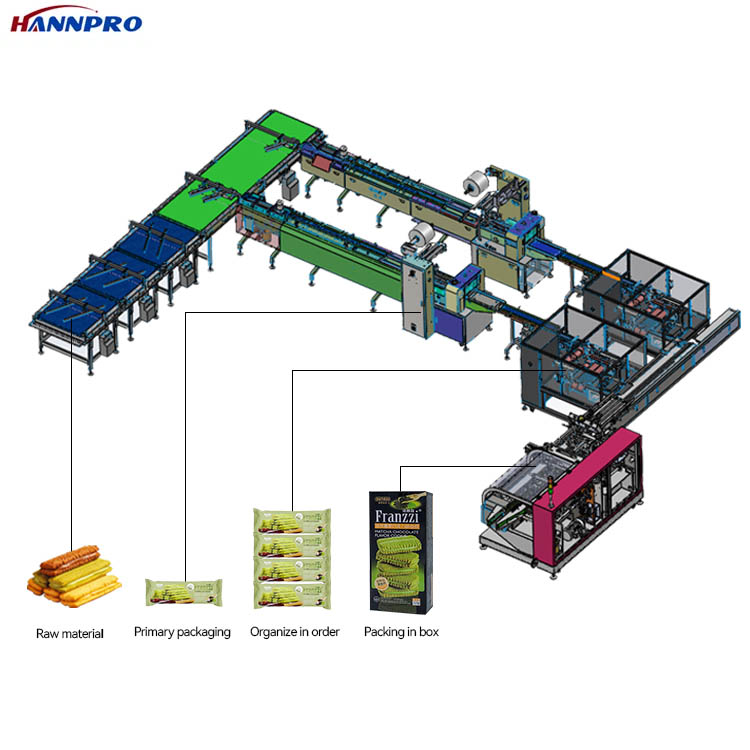

The rounded corner bar and strip packaging multi-row packaging machine is a device used to package bar and strip products into rounded corner strip bags and can perform multi-row packaging simultaneously. The following is an introduction to its working principle, structural composition, features and applications, etc.

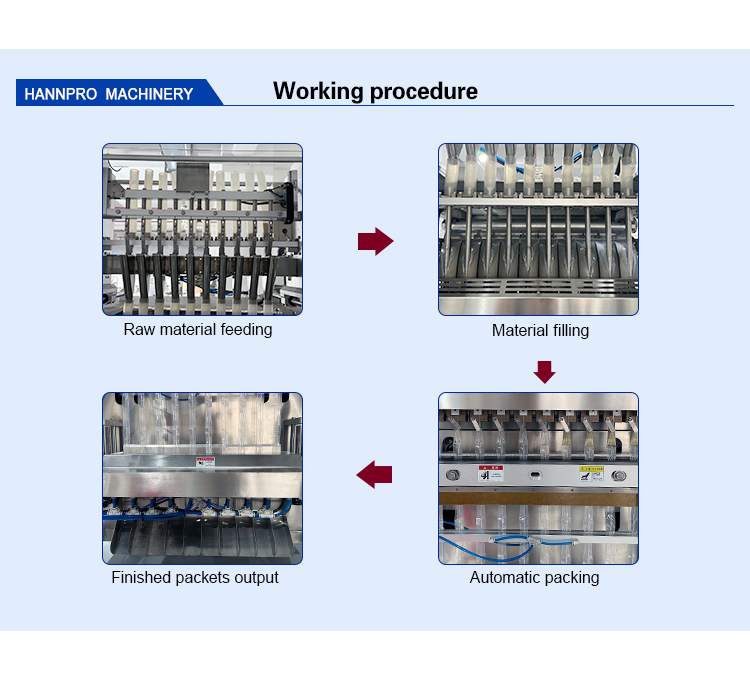

Working principle

Feeding system: Accurately conveys the bar materials to be packaged to the packaging area at the set speed and quantity. Meanwhile, packaging materials (such as plastic films) are unrolled from the rolls and, after passing through a series of guiding and tension control devices, are conveyed to the bag-making and forming mechanism multi-lane packaging machine.

Bag making and sealing: The packaging film is formed into a cylindrical shape through a lapel type or other forming methods, and then the side of the cylindrical packaging film is sealed by a vertical edge sealing mechanism to form a longitudinal sealing edge. After the material filling is completed, the horizontal edge sealing mechanism seals the packaging film horizontally, dividing it into individual rounded corner strip bags multi-lane packaging machine.

Filling materials: During the bag-making process, the feeding system accurately fills the rod-shaped materials into the formed bags. The quantity or weight of the materials in each bag can be controlled through the metering device to ensure the accuracy of packaging stick multi-lane packaging machine.

Cutting and discharging: After sealing the packaging strips, the cutting mechanism cuts them to the set length, divides them into individual rounded corner strip bags to package the finished products, and then discharges them through the discharge port, completing the entire packaging process multi-lane packaging machine.

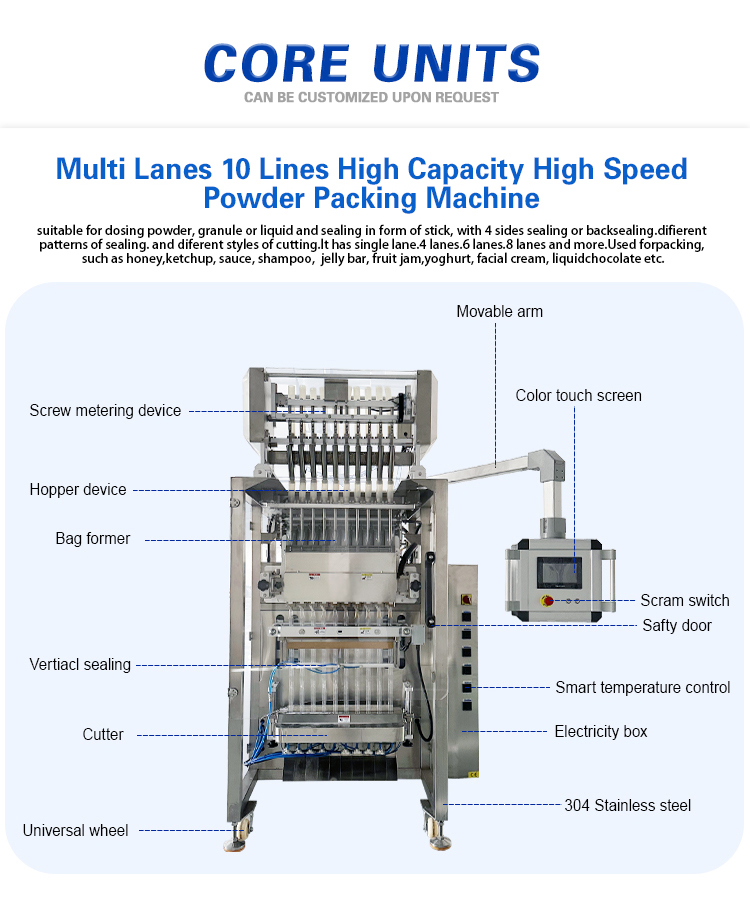

Structural composition

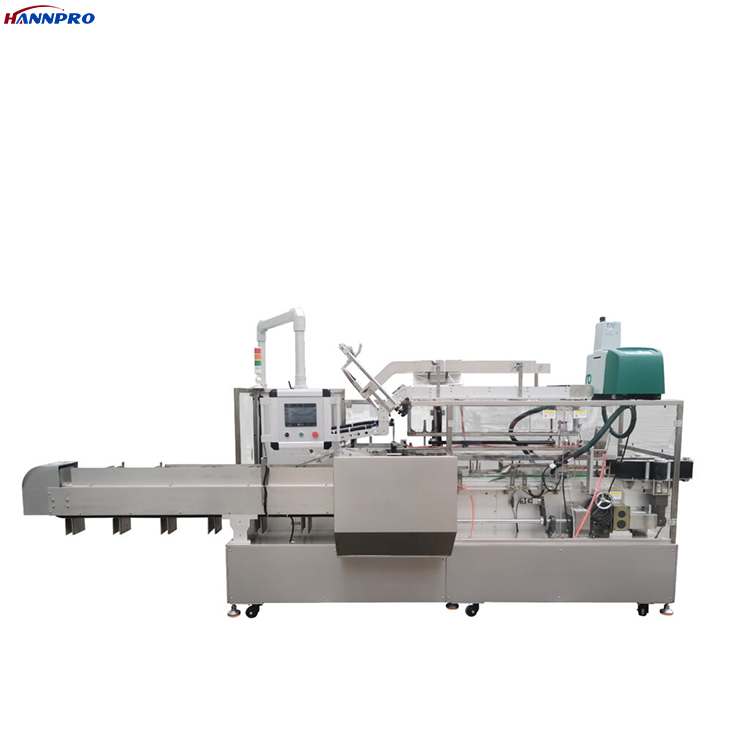

Frame and electrical control system: The frame is used to support all components of the entire packaging machine, ensuring the stability of the equipment. The electrical control system usually adopts PLC (Programmable Logic Controller) in combination with a touch screen operation interface to achieve functions such as parameter setting, operation control, and fault diagnosis of the packaging machine, facilitating the operation and monitoring by the operators multi-lane packaging machine.

Feeding and metering devices: These include feeding equipment such as conveyor belts and vibrating discs for conveying bar materials, as well as metering devices for precisely measuring the quantity or weight of materials, such as screw metering machines and measuring cup metering devices, to ensure that the amount of materials in each packaging bag meets the requirements multi-lane packaging machine.

Packaging film supply and forming mechanism: Composed of film placement brackets, film traction devices, formers, etc., it is responsible for unfolding, pulling and forming packaging film rolls into cylindrical or bag-shaped forms suitable for packaging rods. At the same time, it can be equipped with photoelectric eye tracking devices to ensure the accurate alignment of packaging film patterns stick multi-lane packaging machine.

Edge sealing and cutting mechanisms: Vertical edge sealing mechanisms and horizontal edge sealing mechanisms usually adopt heat sealing technology. By heating and pressurizing, the sides and bottom edges of the packaging film are sealed to form a firm seal. The cutting mechanism generally adopts pneumatic punches or rotary cutters, which can quickly and accurately cut the packaging strips into rounded corner bags of specified length multi-lane packaging machine.

Features of multi-column packaging machines

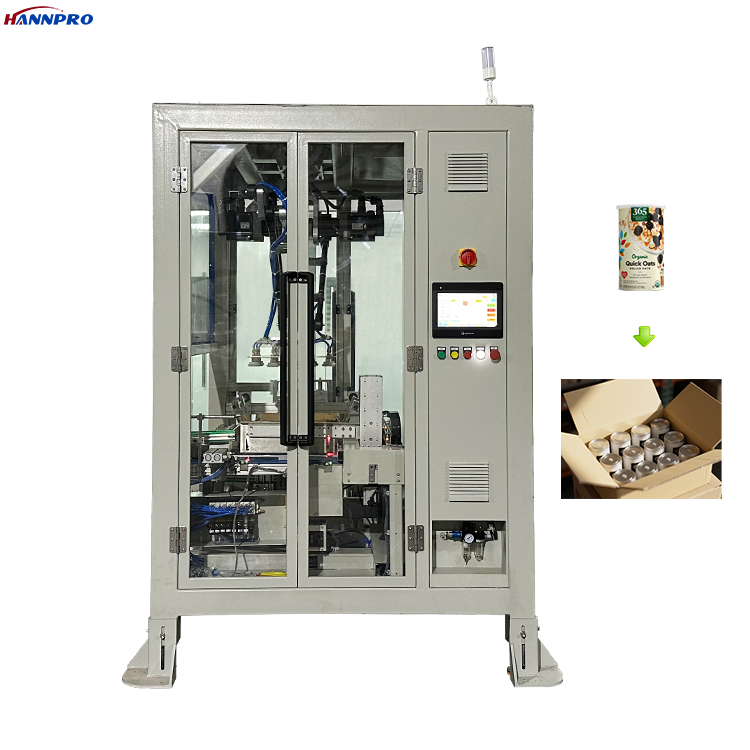

High-efficiency production: The multi-row packaging design enables the machine to package multiple bars simultaneously, significantly enhancing packaging efficiency and meeting the demands of large-scale production multi-lane packaging machine.

High packaging accuracy: Advanced metering devices and control systems are adopted, which can precisely control the filling amount of materials and the size of packaging bags, ensuring the consistency of packaging weight and appearance, and reducing material waste and defective product rates.

Good stability: Through an optimized mechanical structure and electrical control system, the equipment operates stably and reliably, reducing downtime caused by faults, enhancing production efficiency multi-lane packaging machine, and also lowering maintenance costs stick multi-lane packaging machine.

Strong flexibility: According to different bar sizes, packaging specifications and production requirements, various parameters of the packaging machine can be conveniently adjusted, such as bag length, width, sealing temperature, packaging speed, etc. It can also adapt to various packaging materials, such as plastic film, composite film, etc.

Application field

Food industry: such as packaging for candies, chocolate bars, biscuit bars, meat jerky strips and other foods multi-lane packaging machine.

Pharmaceutical industry: It can be used for packaging medicine sticks, capsule strips, ointment strips, etc.

Daily necessities industry: For instance, packaging of stick-shaped daily necessities such as toothpaste, lipsticks, and solid balm stick multi-lane packaging machine.