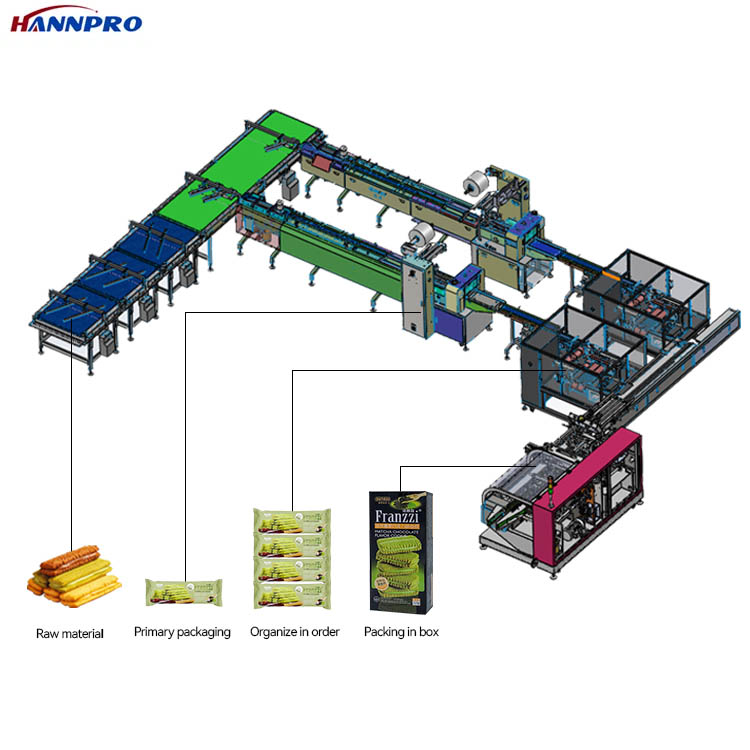

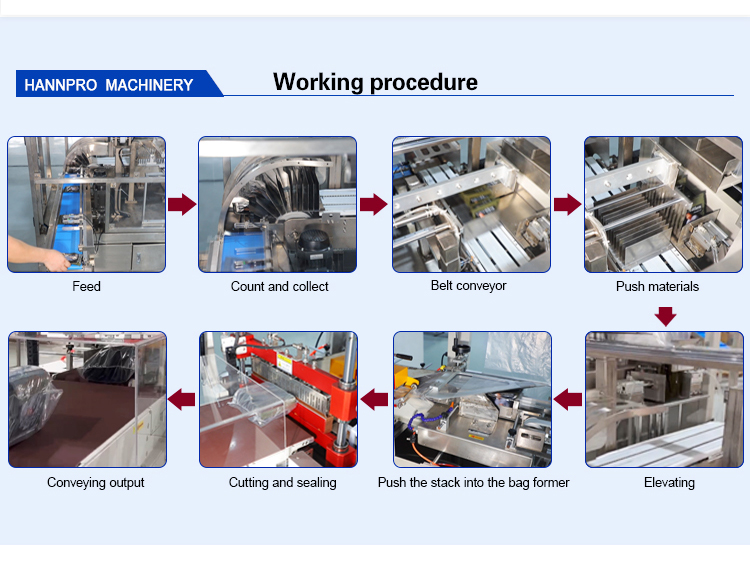

The following is the general implementation of the automatic biscuits packaging machine putting small packages into the medium packages process:

1. Conveying and sorting of small packages of biscuits

Conveyor belt system: Biscuits that have completed independent small packaging are conveyed to the medium packaging area through the conveyor belt.

Arrangement/counting device: Utilizing photoelectric sensors automatic biscuits packaging machine, visual recognition or mechanical baffles to count small packages, and neatly arranging them into groups according to the set quantity (such as 10 packages, 20 packages).

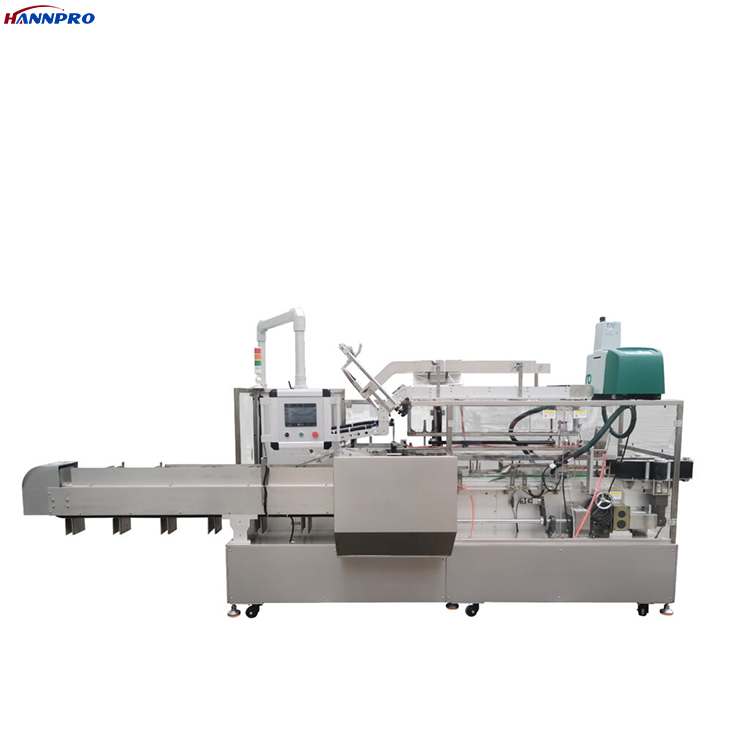

2. Supply and molding of medium bags

Roll film feeding: The middle package uses rolled packaging film (such as composite plastic film automatic biscuits packaging machine), which is automatically fed into the forming device by the unwinding mechanism.

Bag forming: The flat film is rolled and folded into a cylindrical shape through a forming device (such as a set plate or U-shaped forming device) to form the basic shape of the middle bag.

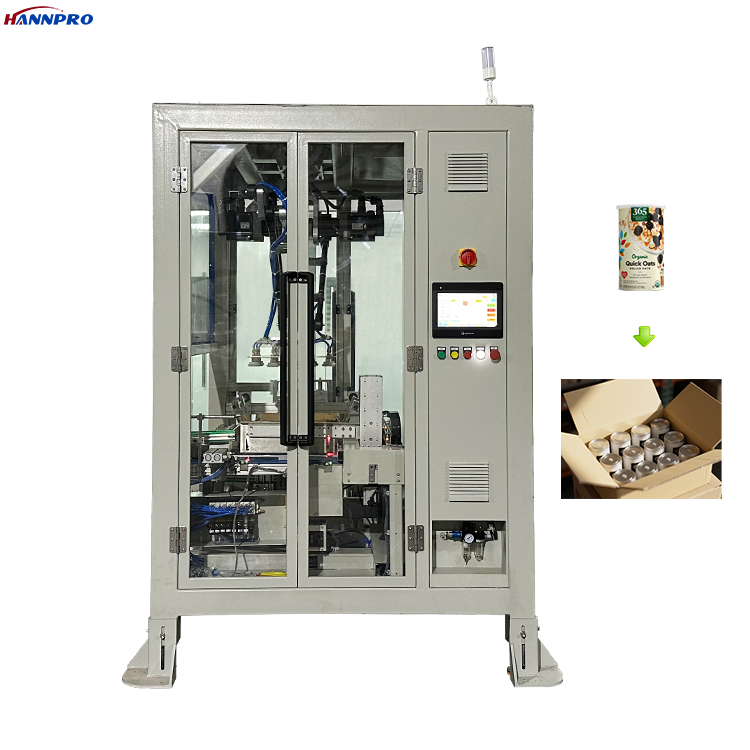

3. Put the small bag into the bag

Feeding/grasping mechanism

Push rod type: A cylinder or servo motor drives the push rod to push the arranged small bags into the already formed middle bag at one time.

Mechanical hand type: It uses multi-axis mechanical arms or vacuum suction cups to precisely grasp and place into bags (automatic biscuits packaging machine suitable for fragile or high-precision products).

Synchronous control: Ensure that the pushing action is precisely synchronized with the position of the bag body to prevent missed loading or material jamming.

4. Sealing and cutting

Vertical seal and horizontal seal

Longitudinal heat sealing seals both sides of the cylindrical film.

Horizontal heat sealing seals the bag opening after loading into small bags and simultaneously cuts the front and rear bags.

Sealing methods: Commonly used are heat sealing, pulse sealing or ultrasonic sealing automatic biscuits packaging machine, and the selection should be based on the material properties.

5. Detection and Rejection

Weight/Quantity inspection: Check whether there are any missing parts in the bag through a load cell or a visual system.

Non-conforming product removal: If any abnormality is detected, the pneumatic push rod or diversion device will remove the defective products from the production line.

6. Control system

The entire process is uniformly coordinated by PLC (Programmable Logic Controller) or industrial computer, in conjunction with servo motors, sensors and human-machine interfaces (HMI), to achieve high-speed, stable and adjustable packaging operations.

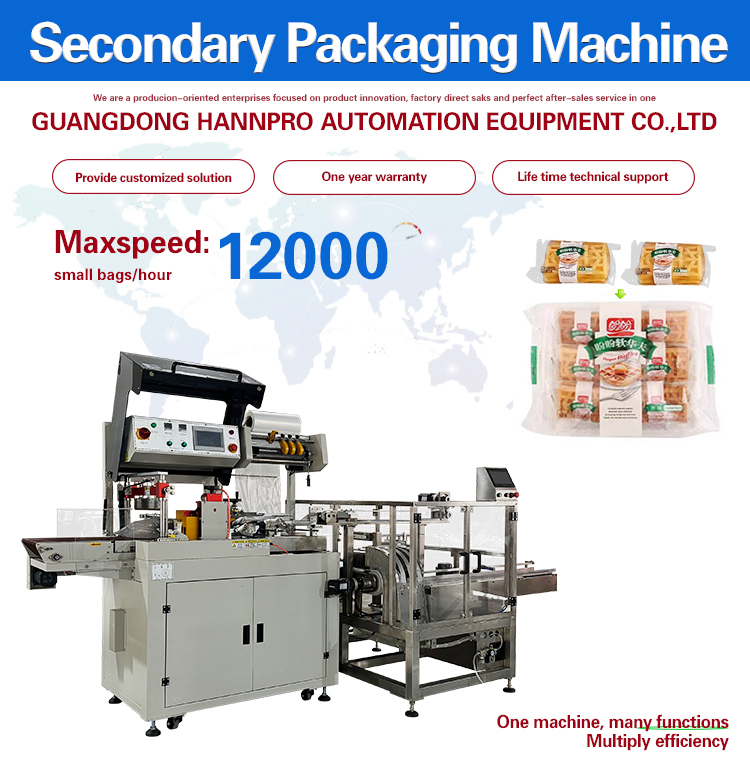

Application example

For instance, a biscuit packaging line might complete 40 to 80 medium-sized packages per minute automatic biscuits packaging machine, with each package containing 12 small packages. The entire process does not require manual intervention; it only needs regular replenishment of packaging film and monitoring of operational status.

If further optimization plans are needed for specific products (such as soft-wrapped/hard-wrapped biscuits), production capacity requirements or packaging forms (pillow type, three-side seal, etc.), more specific equipment selection suggestions can also be provided.