Fully automatic cartoning machine

Working principle

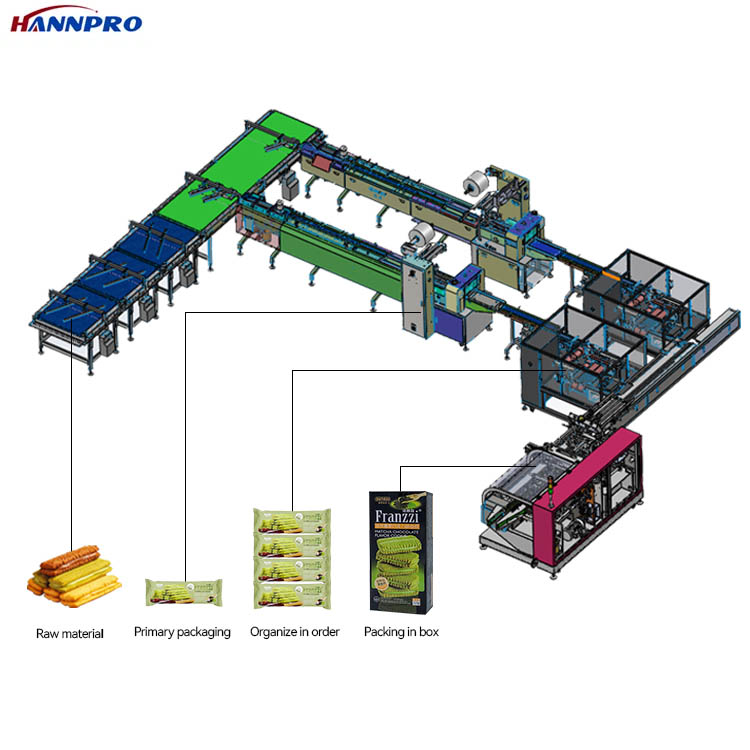

The fully automatic cartoning machine realizes a series of automated operations from product conveying to cartoning, sealing and labeling through a precise mechanical system and control system Fully automatic cartoning machine. The equipment will automatically identify the quantity, size and other information of the products, and make intelligent adjustments according to the preset parameters to ensure that the products are accurately and error-free packed into the boxes.

Generally speaking, its feeding is divided into the instruction manual inlet, the product inlet such as medicine bottles or medicine plates, and the machine packaging box inlet. From the feeding of the machine bag box to the final packaging formation, it can roughly be divided into four stages: lowering the box, opening, filling, and closing the lid Fully automatic cartoning machine.

Structural type

Classified by working mode

Continuous cartoning machine: It is suitable for the high-speed automatic cartoning requirements of small packaged products, including functions such as opening the box, folding the instruction manual, cartoning, sealing the box and printing batch numbers Fully automatic cartoning machine. The equipment features high transmission accuracy, precise positioning and strong stability at high speed.

Intermittent cartoning machine: Mainly suitable for the cartoning requirements of larger-sized products. The motion control module drives the servo motor and actuator, making the operation more precise and stable Fully automatic cartoning machine. The intelligent formula and module guidance make the parameter setting simple. The full balcony design is convenient for maintenance, upkeep and operation. It is adaptable to the feeding and conveying of various specifications of products, with rapid specification switching and stable and reliable conveying.

Classified by structural form

Vertical cartoning machine: It has the advantage of small floor space and is suitable for cartoning various bulk candies, chocolates, biscuits, hardware parts and other products Fully automatic cartoning machine. Some vertical cartoning machines can also be designed in both automatic and semi-automatic modes.

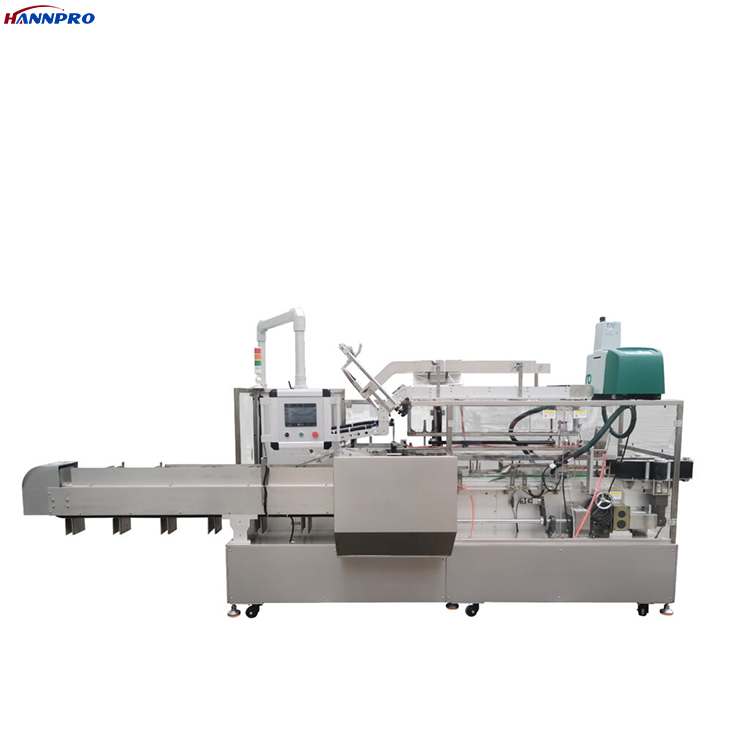

Horizontal cartoning machine: The products are conveyed and cartoned in the horizontal direction. It usually has a high cartoning speed and stability, and is suitable for cartoning products such as medicine plates, tubes, and ampoules Fully automatic cartoning machine.

Main functions

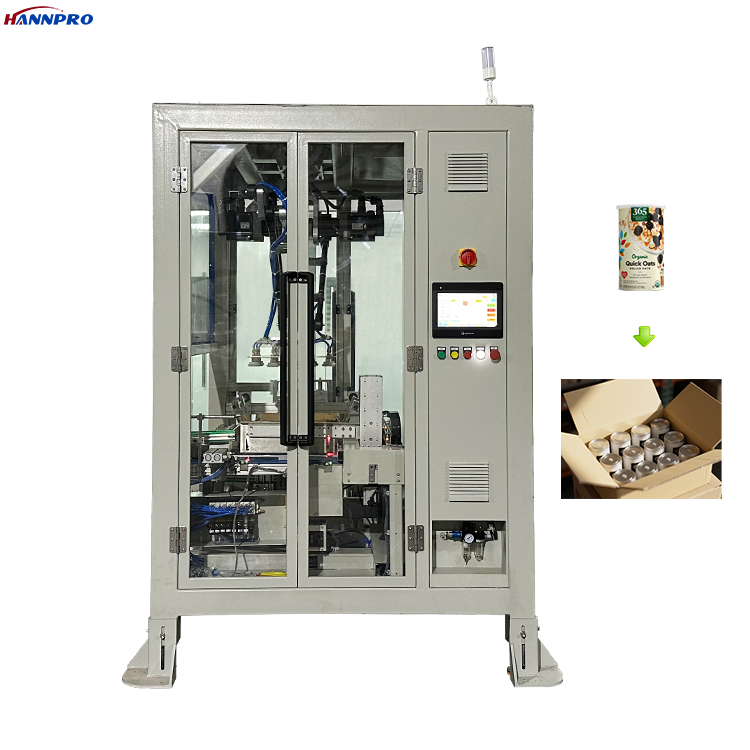

Automatic box feeding: The paper box is sucked from the paper box feeding port by suction cups or other mechanical devices and then lowered onto the main line of box loading.

Instruction manual folding: It can automatically fold the instruction manual in the preset way to accurately place it in the packaging box.

Product filling: Accurately pack various products such as medicine bottles, medicine boards, ointments, toys, and food into open paper boxes Fully automatic cartoning machine.

Sealing the box: After the product is filled, the lid of the paper box is automatically closed, and the box is sealed by means of tongue insertion, adhesive, heat sealing, etc., to ensure that the packaging box is firmly sealed Fully automatic cartoning machine.

Batch number printing: Relevant information such as production date, batch number and validity period can be automatically printed on the packaging box.

Advantages

Improving production efficiency: It can significantly increase the speed of box filling, reduce manual operation links, and shorten the production cycle. For instance, some high-speed fully automatic box filling machines can fill over 100 boxes per minute.

Improving product quality: By adopting precise mechanical and control systems, errors and flaws that may occur during manual operation are avoided, ensuring accurate product packaging.

Reduce production costs: It has significantly reduced labor costs, while also lowering the scrap rate and loss rate during the production process Fully automatic cartoning machine.

Strong adaptability: It is suitable for boxing products of different sizes, shapes and materials. Just make simple parameter adjustments and replace the corresponding molds to meet the boxing requirements of different products Fully automatic cartoning machine.

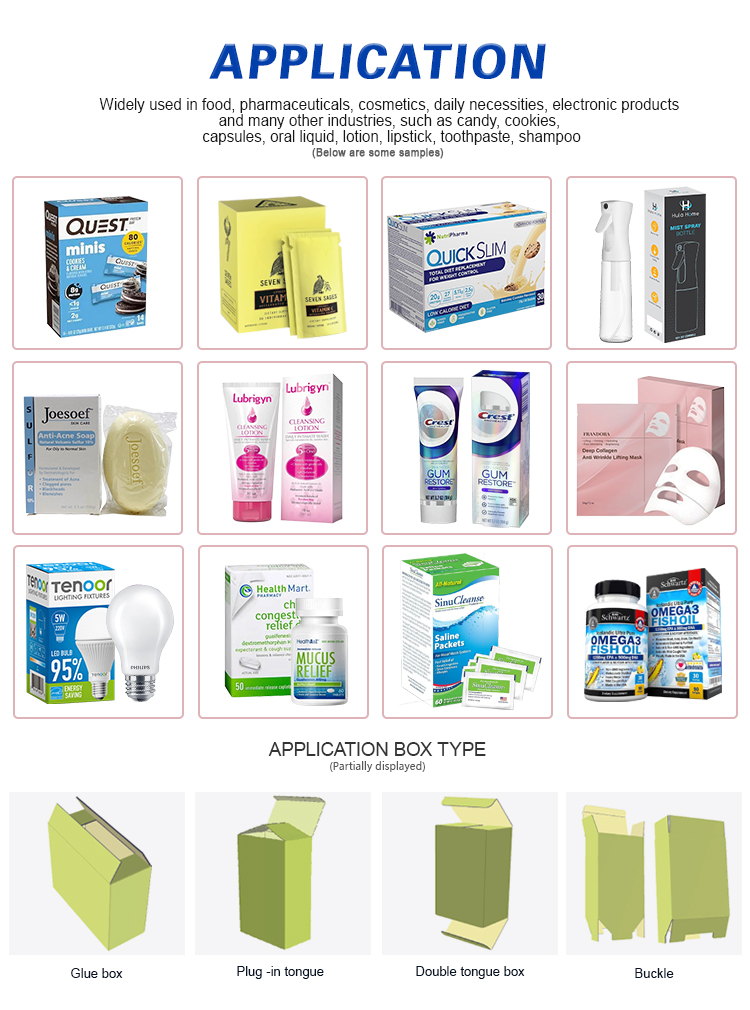

Application fields

Pharmaceutical industry: It is used for boxing medicine bottles, medicine plates, ointments and other medicines, as well as folding and loading instructions to ensure the standardization and hygiene of medicine packaging.

Food industry: such as the boxing and packaging of biscuits, candies, coffee, milk powder, beverages and other foods Fully automatic cartoning machine, to improve the efficiency and quality of food packaging.

Cosmetics industry: It can box cosmetics such as facial masks, facial cleansers, body lotions, perfumes, etc., enhancing the aesthetic appeal and grade of cosmetic packaging.

Hardware industry: Suitable for boxing of hardware accessories such as screws, locks, hinges and cutting tools, facilitating the storage, transportation and sales of hardware products Fully automatic cartoning machine.