Automatic packaging line for powder stick packages

The powder small strip package automatic packaging line is an automated equipment used for packaging small strip packages of powder materials powder stick packaging line. It can be widely applied in the food, pharmaceutical, chemical and other industries, and can realize a series of packaging processes such as powder measurement, filling, sealing and coding, effectively improving production efficiency and packaging quality powder stick packaging line. The following is the relevant introduction:

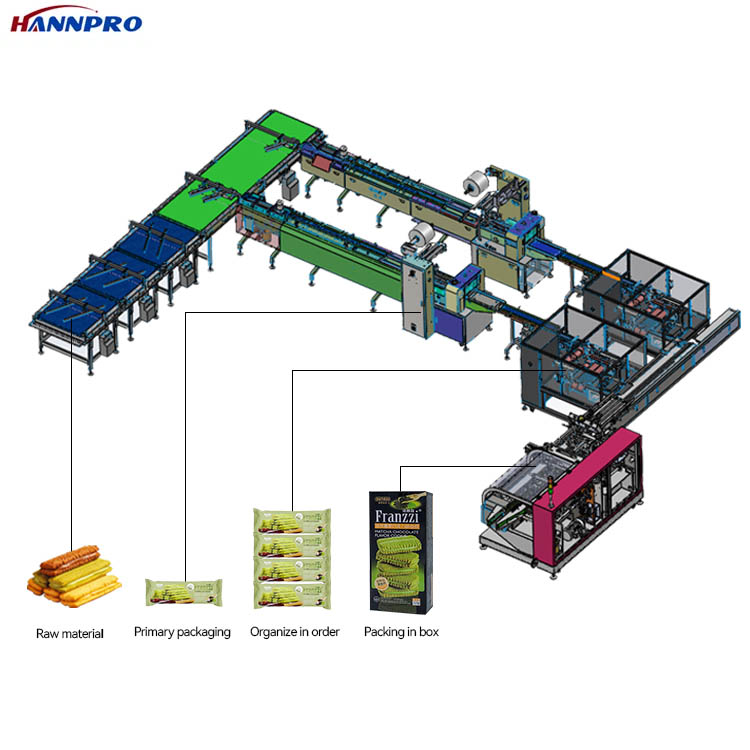

Components

Multi-row bagged powder packaging machine: It is the core equipment, capable of automatically completing operations such as bag forming, powder metering and filling, sealing and cutting, and coding. It can handle multiple product streams simultaneously powder stick packaging machine, thereby increasing the packaging speed powder stick packaging line.

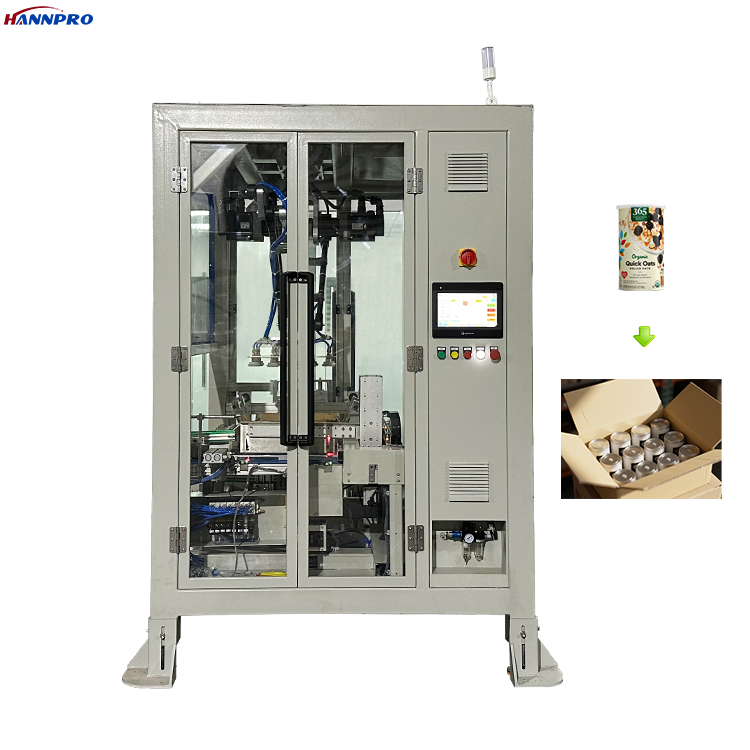

Automatic material sorting machine: It is used to count and organize the packaged powder small strip packages, arrange them in an orderly manner and convey them to subsequent equipment, facilitating operations such as boxing powder stick packaging line.

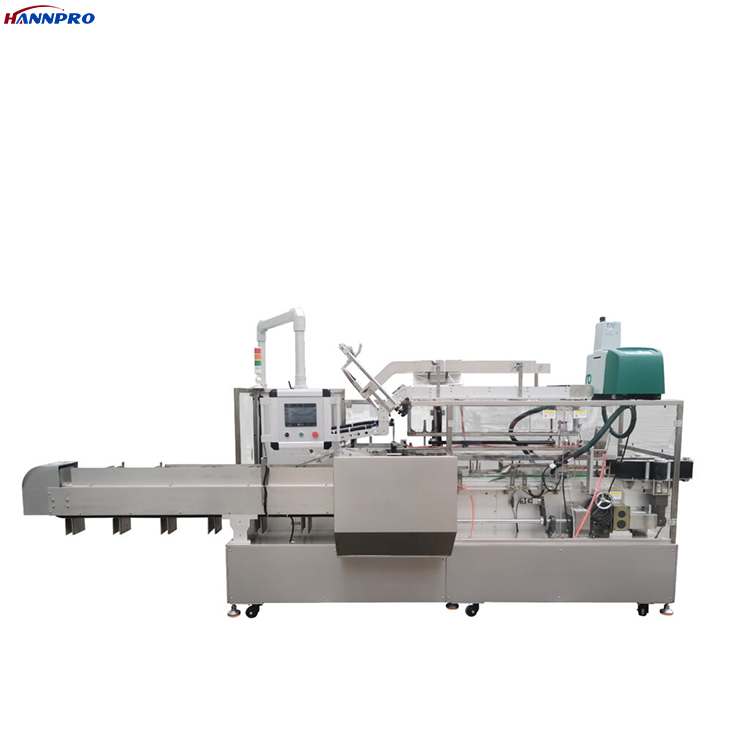

Automatic cartoning machine: It can automatically complete the forming and opening of paper boxes, pack the powder strips conveyed by the material arranging machine into boxes, and then seal the boxes. It is usually equipped with an automatic folding mechanism and a hot melt adhesive machine powder stick packaging line.

Heat shrink packaging machine: It performs heat shrink packaging on products after boxing. By heating, the packaging material shrinks and is firmly attached to the product, enhancing the aesthetic appeal and sealing performance of the packaging, and preventing moisture and contamination powder stick packaging line.

Vacuum feeder: Optional, it is used to automatically convey powder materials from the storage area to the hopper of the packaging machine, achieving automatic material supply and reducing the manual feeding process powder stick packaging machine.

Working principle: The multi-row powder packaging machine precisely fills the powder materials into the packaging film through an automated metering and filling system powder stick packaging line. The coding system prints the identification information, and the sealing and cutting system seals and cuts the packaging film to form small strip packages powder stick packaging line. Then, the automatic material sorting machine counts and organizes the small packages and sends them to the automatic cartoning machine. The cartoning machine completes the operations of box suction, box opening, box loading and box sealing powder stick packaging machine. Finally, the sealed boxes are sent into the heat shrink packaging machine. After the packaging film wraps around the boxes, they undergo high-temperature shrinkage, completing the entire packaging process powder stick packaging line.

Equipment features

High-efficiency production: By adopting a fully automated process, it can quickly complete the powder packaging process and handle multiple rows of packaging simultaneously, significantly enhancing production efficiency powder stick packaging line.

Precise packaging: Equipped with high-precision measurement and control systems, it ensures the accuracy of the packaging quantity of each package of powder and good product consistency powder stick packaging machine.

Hygiene and safety: Generally made of food-grade materials and stainless steel, it meets hygiene standards. The fully enclosed packaging structure can reduce dust overflow. Some equipment is also equipped with built-in dust removal devices powder stick packaging line.

Easy operation: Generally, a human-machine interface operating system is adopted, which is simple and intuitive to operate powder stick packaging machine. It also has the function of automatic detection and alarm for equipment faults, making maintenance convenient.