Automatic packaging line for meal replacement powder

The automatic packaging line for meal replacement powder is an automated device used for packaging meal replacement powder. It can realize the automated operation of a series of packaging processes from metering, bag making to sealing and output of meal replacement powder, which can effectively improve production efficiency and ensure packaging quality. The following is its relevant introduction:

Components

Feeding device: It is usually composed of a storage bin and a conveying mechanism Powder Stick Packing Line. The storage bin is used to store meal replacement powder, and the conveying mechanism conveys the meal replacement powder from the storage bin to the metering device. Common types include screw conveyors, etc., which can stably transport the powder to the designated location.

Metering device: Generally, screw metering structure or load cell metering is adopted Automatic packaging line for meal replacement powder. The screw meter controls the feeding amount through the rotation of the screw and can precisely measure a certain amount of meal replacement powder according to the set parameters. The weighing sensor measurement can monitor the weight of the materials in real time to ensure that the amount of meal replacement powder in each packaging bag meets the specified requirements.

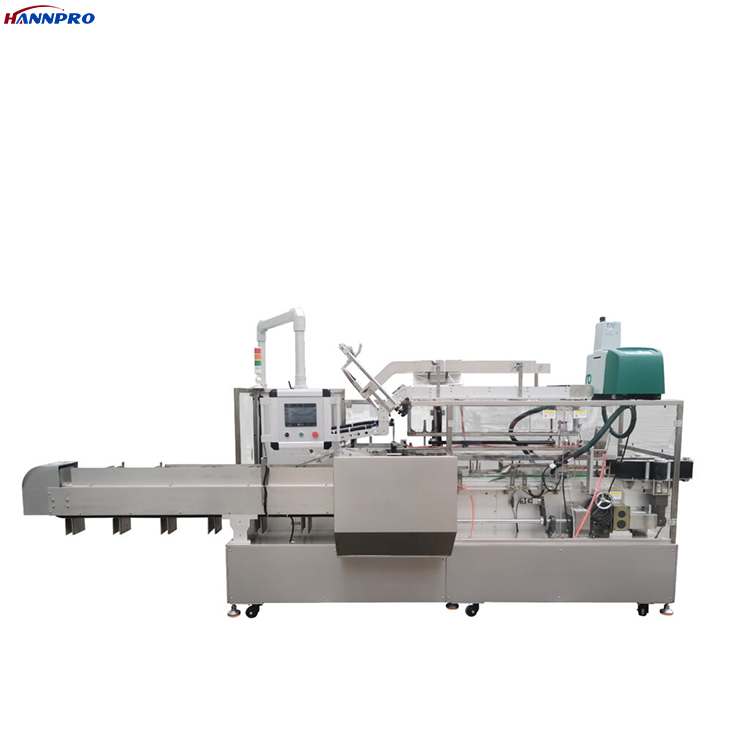

Bag-making device: Mainly composed of bag-making machine, heat sealing device and cutting knife, etc. Packaging materials (such as composite films) are automatically bag-pulled and heat-sealed by bag-making machines to form packaging bags of preset sizes and shapes, and then cut by cutters to the preset lengths.

Filling device: Fill the measured meal replacement powder into the prepared packaging bags, usually working in conjunction with the metering device to ensure the filling process is accurate and efficient.

Sealing device: Heat sealing is mostly adopted Automatic packaging machine for meal replacement powder. The temperature is controlled by an enhanced heat sealing mechanism and an intelligent temperature controller, making the sealing pattern of the packaging bag clear and the sealing performance strong. Some equipment also uses other methods such as ultrasonic sealing.

Inkjet coding device: It is used to print production date, shelf life, batch and other information on packaging bags Powder Stick Packing Line. Generally, a laser coding machine is adopted. The coding content is clear and visible, and can be conveniently modified in a computer.

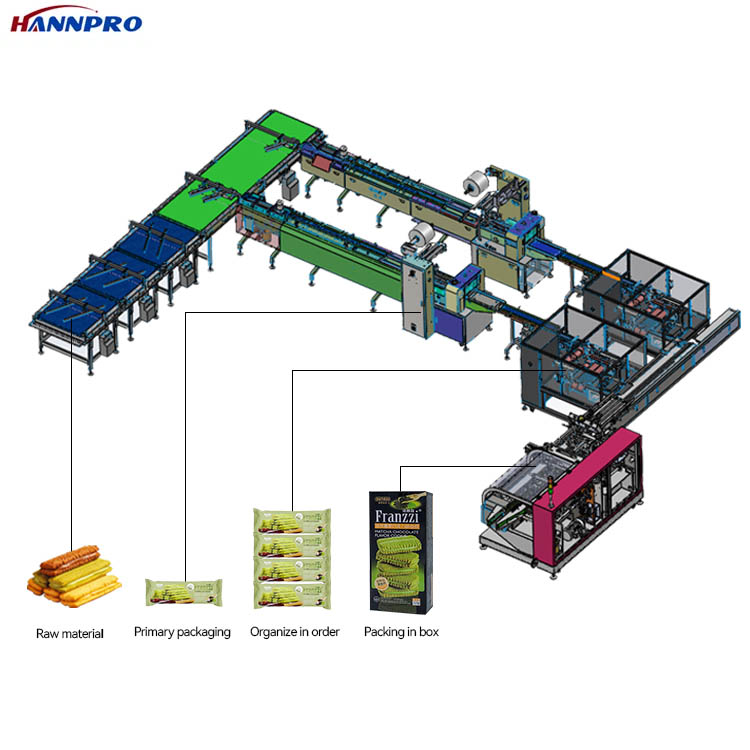

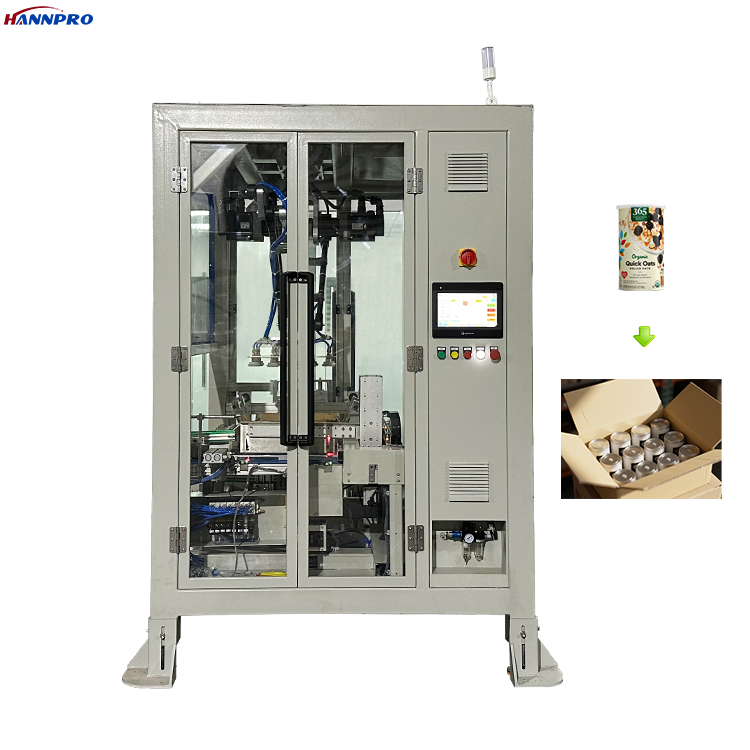

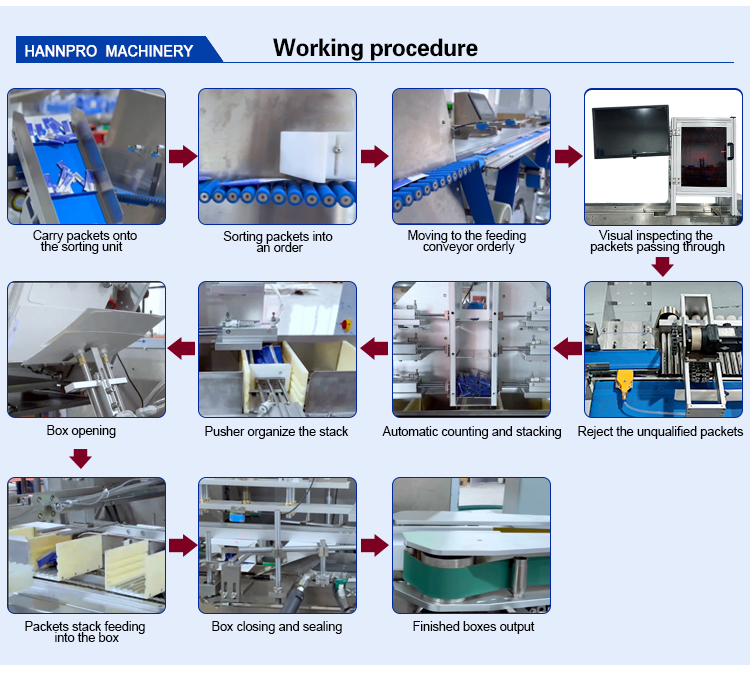

Conveying device: Driven by a motor and transmitted through chains or belts, it conveys materials from one process to the next, ensuring the continuity of the meal replacement powder packaging process Automatic packaging line for meal replacement powder. At the same time, it can also transport finished products to the subsequent palletizing or boxing areas Automatic packaging machine for meal replacement powder.

Control system: It usually adopts the form of PLC (Programmable Logic Controller) combined with touch screen Powder Stick Packing Line. Operators can set various packaging parameters through the touch screen, such as bag length, packaging weight, packaging speed, etc. The PLC is responsible for precisely controlling and coordinating each component of the entire packaging line.

Working principle: Firstly, the meal replacement powder is sent into the metering device by the feeding device. The metering device accurately measures a certain amount of powder according to the preset parameters. Then, the packaging materials are formed into packaging bags by the bag-making device, and the measured meal replacement powder is filled into the bags by the filling device. Then, the sealing device performs heat sealing on the packaging bag, which is then cut by a cutter to form an independent package. Finally, the finished products are sent out by the conveying device, completing the packaging process.

Equipment features

High degree of automation: It can automatically complete multiple packaging processes such as metering, bag making, filling, sealing, cutting, and coding, reducing manual intervention and lowering labor costs Automatic packaging machine for meal replacement powder.

Precise measurement: It can achieve high-precision measurement, avoiding errors and missed packages, etc., ensuring that the weight of each bag of meal replacement powder meets the standard Automatic packaging line for meal replacement powder.

Fast packaging speed: It can work continuously and stably, meeting the demands of large-scale production and enhancing production efficiency Automatic packaging machine for meal replacement powder.

Convenient operation and maintenance: The humanized touch screen display makes it easy for operators to view the output and set parameters, and the replacement and cleaning of equipment components are relatively convenient.

Strong adaptability: It can be customized and modified according to different packaging requirements and product types, and can adapt to various specifications of packaging bags and different types of meal replacement powder packaging Powder Stick Packing Line.