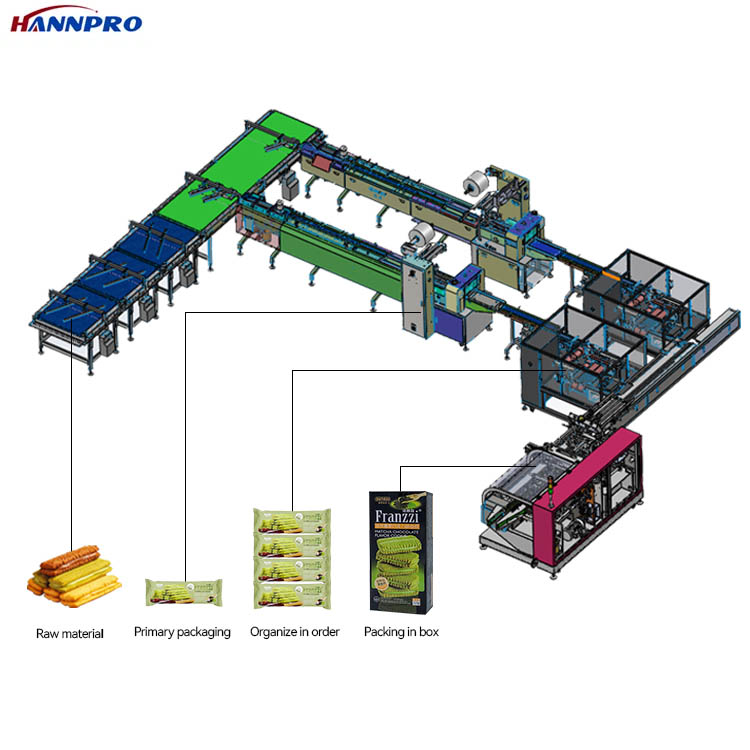

The automatic packaging line for lip cigarettes is an automated production line used for packaging lip cigarette products Snus Packing Line. It can complete a series of processes from raw materials to finished product packaging for lip cigarettes Snus Packing Machine. The following is its related introduction:

Equipment composition

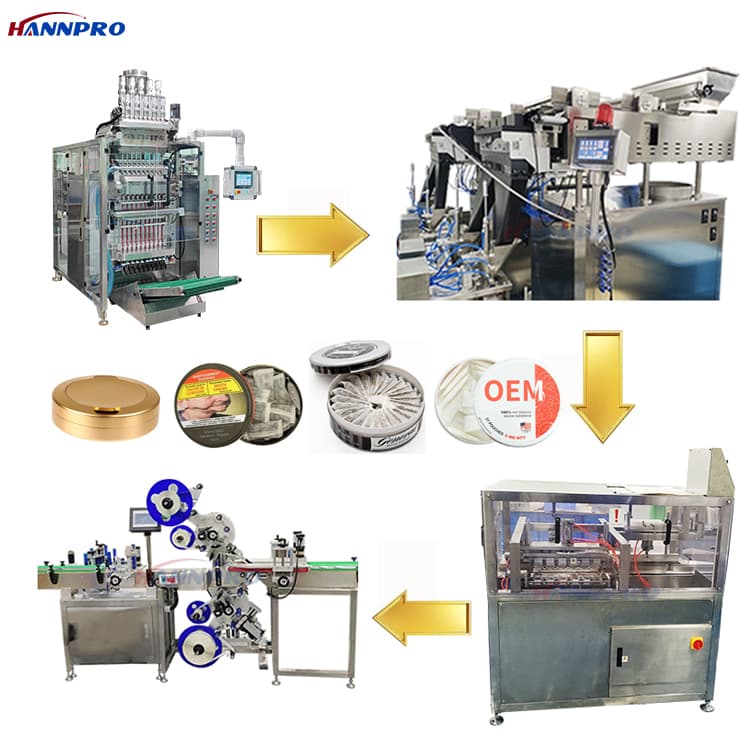

Packaging machine: Commonly used ultrasonic cigarette packaging machine, which achieves sealing through the principle of ultrasonic vibration Snus Packing Line. During packaging, the machine converts ultrasonic energy into high-frequency vibration, which is then conducted to packaging materials such as non-woven fabrics through specific welding heads, causing the materials to melt and bond instantly to complete the sealing Snus Packing Machine. This process is fast, and the sealing is firm and aesthetically pleasing. It is suitable for various packaging materials such as films and non-woven fabrics Snus Packing Line.

Metering equipment: The lip cigarette packaging machine is equipped with a precise metering system, such as electronic scales or volumetric metering devices,Snus Packing Machine etc., to ensure that the weight or quantity of each package of lip cigarettes meets the preset standards, satisfies consumer demands, and saves raw material costs for enterprises Snus Packing Line.

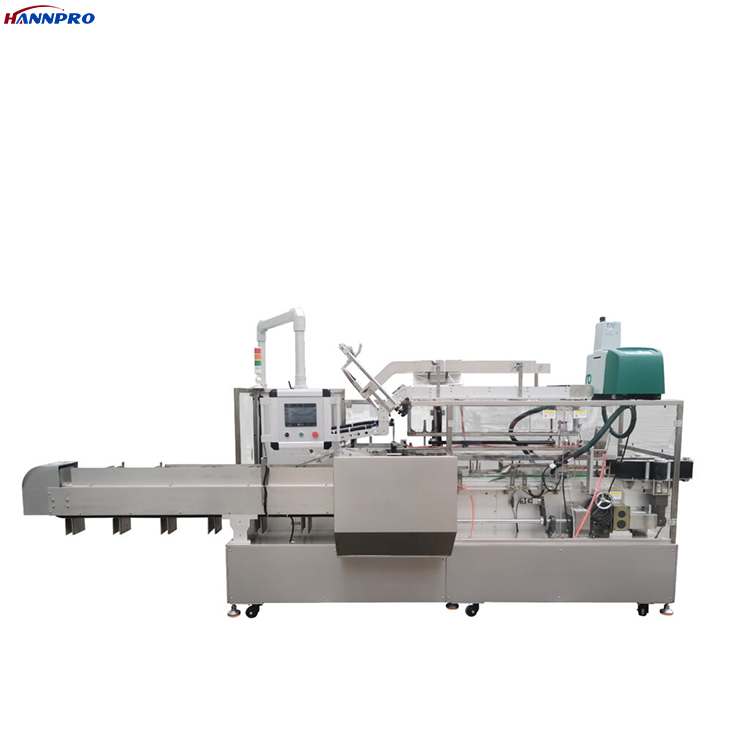

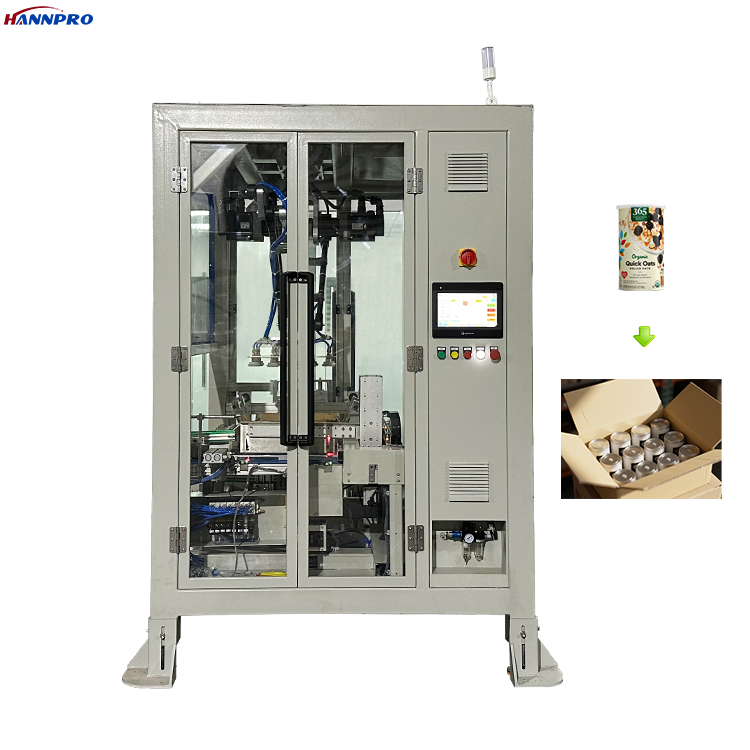

Cartoning machine: It places the packaged lip cigarette products into packaging boxes to achieve further packaging of the products Snus Packing Machine, facilitating transportation and sales. Some cartoning machines also have functions such as automatic box opening and sealing Snus Packing Line.

Labeling machine: It can automatically stick labels on packaging boxes or product packaging. The label content usually includes product name, specification, production date, shelf life, brand logo and other information, which is helpful for product identification and market promotion Snus Packing Machine.

Heat shrink machine: It performs heat shrinkage treatment on products after labeling, causing the labels or outer packaging to shrink and adhere to the products, achieving both aesthetic and protective effects for the products Snus Packing Line.

Working principle

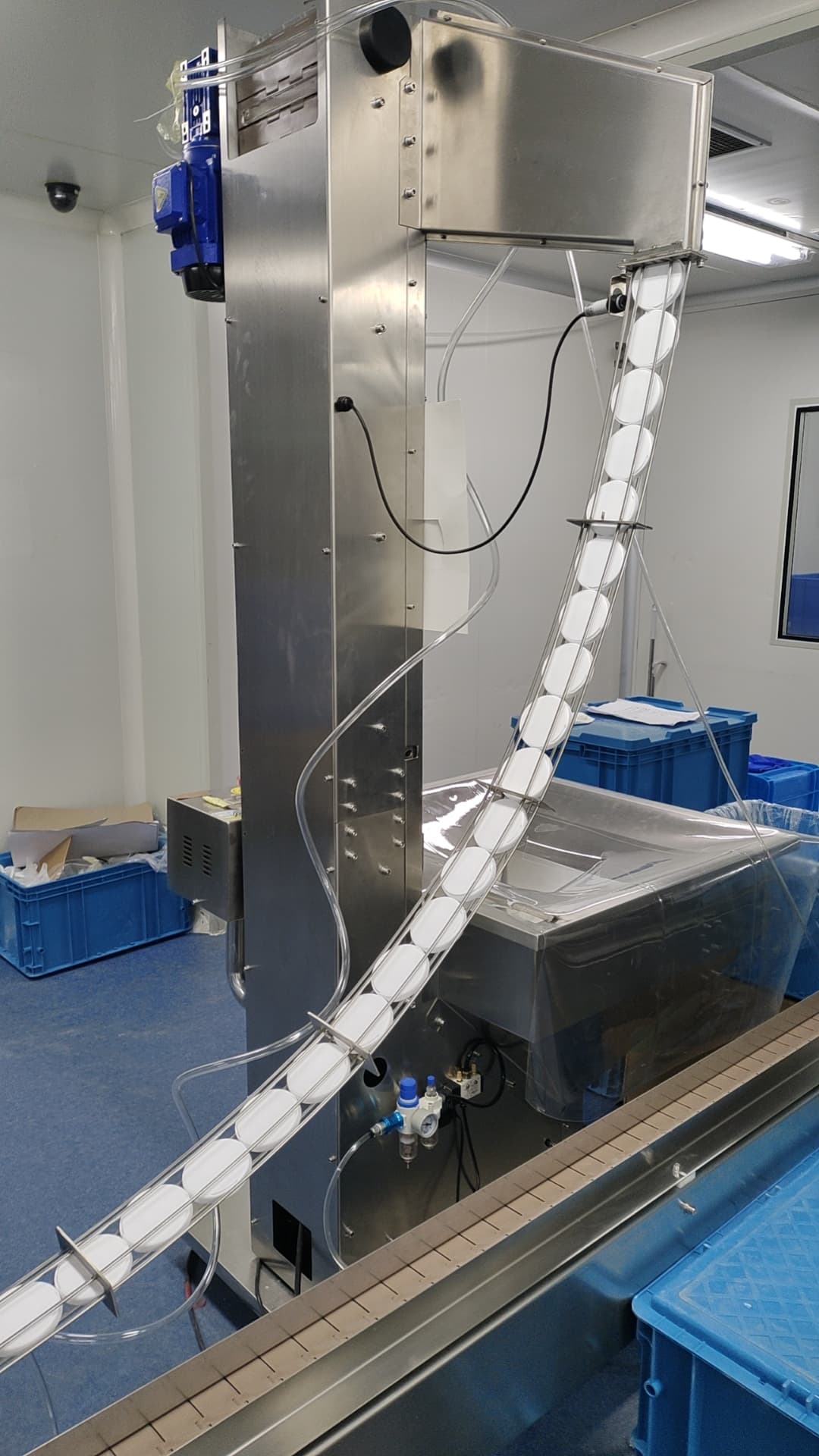

Automatic feeding: The raw materials of lip smoke are automatically conveyed to the packaging position through conveyor belts or other feeding devices. During the feeding process Snus Packing Machine, precise measurement can be carried out through metering equipment Snus Packing Line.

Packaging forming: The packaging material (such as non-woven fabric) is unrolled from the reel and passes through the ultrasonic sealing device Snus Packing Machine. Under the action of ultrasonic energy, the packaging material seals around the lip cigarette raw material to form the initial packaging product Snus Packing Line.

Boxing and labeling: The packaged lip cigarette products are conveyed to the boxing machine for boxing Snus Packing Machine, and then labels are affixed at the corresponding positions by the labeling machine Snus Packing Line.

Heat shrink and finishing: After the products are boxed and labeled, they enter the heat shrink machine. Through heating Snus Packing Machine, the packaging labels or films shrink to tightly wrap the products. Finally, they undergo finishing and inspection. Qualified products can proceed to the next stage Tobacco Pouches Packing Line.

Technical characteristics

High degree of automation: By adopting automation technology, it realizes the full automation operation of a series of processes from measurement, filling, sealing, coding to boxing, labeling, and heat shrinkage, reducing manual intervention, improving production efficiency, lowering labor costs and errors caused by human factors, and enhancing the stability of product quality Snus Packing Machine.

Precise measurement: Equipped with a high-precision measurement system, it ensures that the weight and quantity of each pack of lip cigarettes are accurate and meet the preset standards Snus Packing Machine.

Diversified packaging: According to market demand, packaging of different specifications, shapes and materials can be achieved. The flexible packaging method helps enterprises expand their product lines and meet consumers' personalized demands Snus Pouches Packing Line.

Advantage

Enhance production efficiency: It can operate continuously at high speed, completing multiple packaging cycles per minute. Compared with manual packaging, its efficiency is significantly improved, meeting the demands of large-scale production Snus Packing Machine.

Ensuring product quality: Automated operation reduces the influence of human factors, making the packaging quality of each pack of lip cigarettes more stable Snus Packing Machine. The sealing is firm, the label application position is accurate, and the product appearance is uniform, enhancing the overall quality and market image of the product Snus Packing Machine.

Reduce costs: Decrease the use of labor and lower labor costs Snus Packing Machine; The precise measurement system avoids the waste of raw materials and can reduce the production costs of enterprises in the long term Snus Packing Machine.